Our Team

Alex Morcate

I am a fourth year mechanical engineering student at Cal Poly. I look forward to graduating in 2020 and starting full time at my job in project management.

Chloe Ng

I’m a 4th year Mechanical Engineer interested in using my mechanical engineering background to help others and hope to enter the biomedical/healthcare industry after graduation. In my free time, I enjoy eating at new restaurants and like to stay active through running and playing sports.

Alexander Cherry

I am a fourth year ME. I have a background in FRC robotics, but am pursuing a career in Construction Management. I plan to be a Project Manager five years after graduation working for a general contractor building large scale multi-family projects across the Bay Area. I am an avid scuba diver and enjoy mountain biking.

Tyler (Mikio) habu

I am a 4th year Mechanical Engineering major. I am looking to go into either the medical technology industry or fire protection engineering industry after graduation. In my free time I enjoy working out, photography, and watching and playing sports.

Acknowledgements

Thank you to Dr. Brian Self for being our faculty advisor through the duration of this project, Vanessa Salas for being our QL+ advisor and the Quality of Life Plus organization for funding our project.

Our Project Videos

Our Project's Digital Poster

Problem Statement

Initially, Ret. Major Peter Way needed an efficient lifting and storing mechanism for his wheelchair that takes up a minimal amount of space in the back seat of his truck cab. Space is limited and collaboration with the Dog Ramp team is necessary. Storing the chair in the bed of the truck was not an option because the wheelchair would not be protected from the outside elements. However, focus has shifted away from a lifting device to a universal, easy to use, storage system for his wheelchair. The system allows for quick and secure loading and unloading of his wheelchair and keeps it from damaging the truck, others, or itself while in motion.

Design Constraints

Fits in the available space within the backseat of the truck cab

Fit and deployment works with the dog and Dog Ramp teams device

Mechanical Layout

Both racks use a modular headrest plate interface allowing them to be installed in any vehicle with a standard two post headrest

All components are steel with a rubberized corrosion resistant coating

The majority of the components are commercial off the shelf products which means replacement parts are readily available

Both racks have been designed and tested to securely store their respective wheelchair components both under static and dynamic conditions with a minimum factor of safety of 2

The overall weight of both racks combined was kept under 15 lbs in order to make transfer and installation as easy as possible.

Part replacement and maintenance only requires 7/16” wrenches

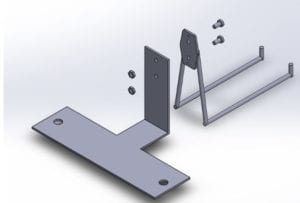

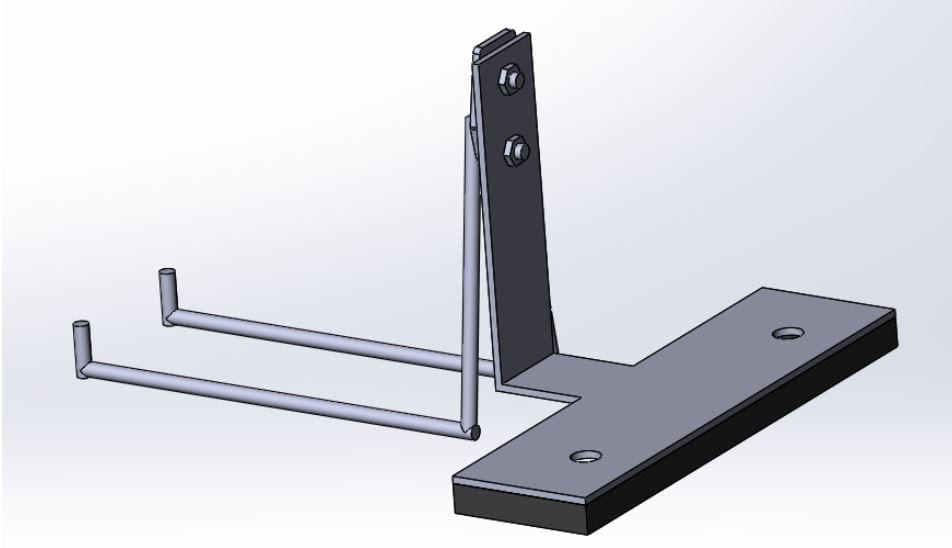

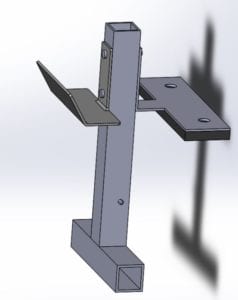

Wheel storage rack shown in an exploded view above. It is designed to attach to the back of either the driver’s or front passenger’s headrest.

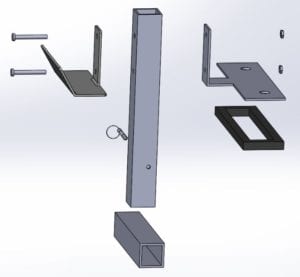

Wheelchair storage rack shown in an exploded view. It is designed to attach to the rear passenger seat using the headrest and child seat connectors.

Design Concept

Storage rack secured to back of driver’s seat with wheels placed on hook arms

Storage rack secured to backseat headrest with wheelchair placed on hooked shelf

These CAD models allowed us to ensure that both storage systems allowed the wheelchair and wheels to be stored in the appropriate amount of space.

This project is sponsored by Quality of Life Plus

Design Analysis

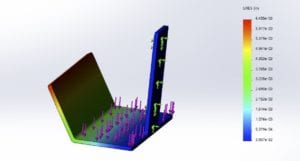

Shown is the Deflection of Final Shelf Design, Loaded with 120 lbf during a Solidworks Simulation.

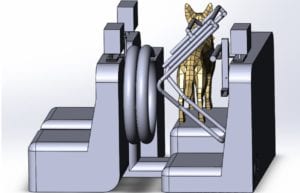

The expected storage arrangement for the wheelchair (front right) and wheel (front left) racks and dog ramp (back left).

(left): Areas of red indicate more deflection in the vertical direction than areas of blue. The Shelf Design deflects minimally, still within acceptable ranges. This simulation was then verified with physical testing.

(right): The team’s greatest challenge was maximizing the effectiveness of the space available and sharing it with the other team tasked with helping Peter’s service dog, Rory. The two teams collaborated to develop integrated solutions that fit nicely in Peter’s backseat.

Manufacturing Process and Components

Design Verification

In order to test the deflection on the hook, we took weights , placed them on the rack (shown above), and drove around to replicate the natural bumps of the road.

Our team was able to send out a fully functional prototype to Peter to test out himself. He has been using it for the past few months and has assured our team that our storage solution has been working really well for him. He has also provided us with some feedback which we hope to incorporate in a future design.

While we were not able to take a Toyota Tacoma out on a test drive, we did install both storage systems in one of our cars. We loaded both racks with 25 lbs on each hook arm to test for deflection. We also loaded the wheel rack with a set of wheelchair wheels to test how much noise they made while driving around. The wheelchair storage rack we tested used a different set of hook arms. These arms experienced significant vertical deflection which led us to redesign this rack incorporating the new shelf hook.

Final Design

Specifications

2 Systems: Wheelchair Rack and Wheel Rack

Wheelchair Storage Rack Weight Capacity: 120 lb

Wheel Storage Rack Weight Capacity: 50 lb (?)

Storage Time: < 2 minutes

Custom Components

Headrest plates

Wheelchair Rack T-frame

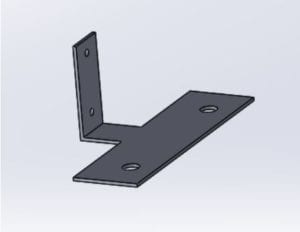

Wheelchair Shelf Hook

L bracket

Stock Components

Car Seat Straps

¼-20 – 2.25” SHCS

¼-20 Nylon Lock Nut

Hitch Pin ¼” x 1-¾”

Wheel Hooks

Future Application

The modular design of the storage racks allow them to be used in any vehicle that has adequate space. Further, the child seat safety connector buckles used to secure the wheelchair rack are compatible with all cars produced after 2001. If QL+ decides to move forward with this design they would be able to install these storage racks in most vehicles with little to no modifications to the design and no permanent damage to the vehicle.

CAD model of the modular headrest interface design. This allows the racks to be used with any vehicle that has a standard two post headrest layout.

The child safety seat connectors used to secure the wheelchair storage rack can attach to all vehicles that have child seat hooks.

Image of the storage rack installed on a Toyota Tacoma. The design does not require any permanent modification of the vehicle in order to be installed.

Recommendations

Improvements to the design if we were to redesign our product:

Adjustable rack height

Aluminum over steel

Fewer custom parts

Wheel rack redesign to keep from sagging