Our Team

Journey Martinson

I am a 4th year Mechanical Engineering student at Cal Poly. I will be graduating in June of 2020 and I’m planning on pursuing a career in the HVAC industry.

Spencer Goodman

I am a 5th year Mechanical Engineering student at Cal Poly. I will be graduating in December of 2020 and I’m planning on pursuing a career in the robotics industry.

Jake WAlejko

I am a 4th year Mechanical Engineering student at Cal Poly. I will be graduating in December of 2020 and I’m planning on pursuing a career in the aerospace industry.

Kalina Burns

I am a 5th year Mechanical Engineering student at Cal Poly. I will be graduating in June of 2020 and I’m planning on pursuing a career in manufacturing design.

Acknowledgements

We would like to thank our faculty advisor Dr. Brian Self for his devotion to all of the senior project teams this year. We would also like to thank Home Depot, Lowes, and Traffic Management Inc. for their generous donations to our team.

Our Project Video

Our Project's Digital Poster

This project is sponsored by…

Achievement House, Inc.

Problem Statement

The overall objective of the project is to design and manufacture adaptive exercise equipment for people with varying levels of mental and physical disabilities. Non-adapted exercise equipment does not have the safety features, support, or wheelchair features necessary to allow a wide range of people to participate. In addition, adaptive exercise equipment on the market today is expensive, which makes it challenging for non-profit organizations such as Achievement House to provide such equipment for their clients. Introducing adapted exercise equipment into their fitness class will allow more athletes to participate, which will create a more inviting environment and help encourage socialization and community. Our goal is to develop adapted exercise equipment that will allow people with mental and physical disabilities to exercise various muscle groups at varying levels of difficulty by developing specialized equipment specifically for their client’s unique range of motion, strength, and dexterity.

Design Constraints

- Accessible to athletes that use wheelchairs

- Able to target multiple major muscle groups

- Fits in the Achievement House exercise room

- Easy for athletes to use

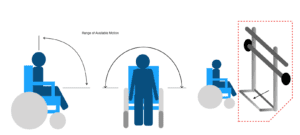

Boundary Diagram

The user should be able to remain seated in their wheelchair while performing the workout.

The image above is the exercise room at Achievement House. We were told that the equipment we designed can be placed anywhere in the room. The team decided that the best location would be against the back wall where Jake and Journey can be seen measuring the length.

Analysis

Concept Designs

The upper body elliptical functions similarly to a typical elliptical machine, but it is designed for a wheelchair user to achieve cardio exercise with their upper body.

The adaptable rowing machine has space for a wheelchair user to lock into the machine and then perform a rowing exercise.

The hand pedaler works similarly to a stationary bike, but a wheelchair user is capable of rolling up the machine and achieving a cardio workout using their arms. The resistance would be adjustable to allow the user to control the difficulty of the exercise.

The adaptable rowing machine has space for a wheelchair user to lock into the machine and then perform a rowing exercise.

Final Design

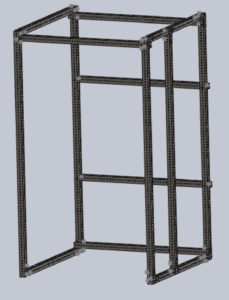

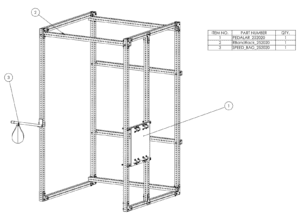

Resistance Band Rack

Dimensions: 7.5 ft x 4 ft x 4ft

The resistance band rack is designed to have hooks placed on it wherever the trainer desires. Resistance bands can be attached to these hooks, and a wheelchair user can roll into the structure and complete various exercises.

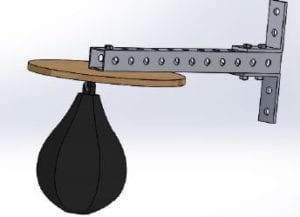

Punching Bag

Dimensions: 1.5 ft x 1.0 ft

The punching bag attachment was included for a specific athlete that stressed her interest in boxing to the team. The punching bag can be placed at different heights to allow it to be used by those standing or sitting down.

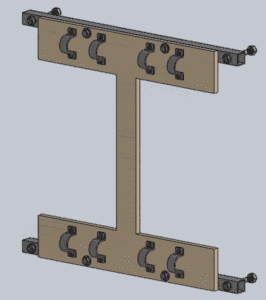

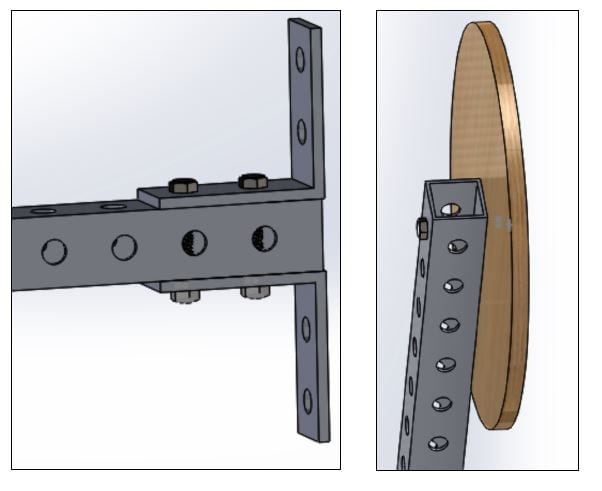

Pedaler Attachment

Dimensions: 1.5 ft x 1.5 ft

The pedaler attachment was included to help the athletes achieve a cardiovascular exercise. A portable pedaling device can be attached to the brackets shown above. The attachment can be placed at different heights so that it can be used for pedaling with the arms or with the legs. The resistance of the pedaling motion can be adjusted for the athletes’ varying ranges of strength.

The final design is comprised of the resistance rack as well as the punching bag and pedaler attachments. Three athletes can complete a workout at once with this design, and all three stations are accessible to wheelchair users.

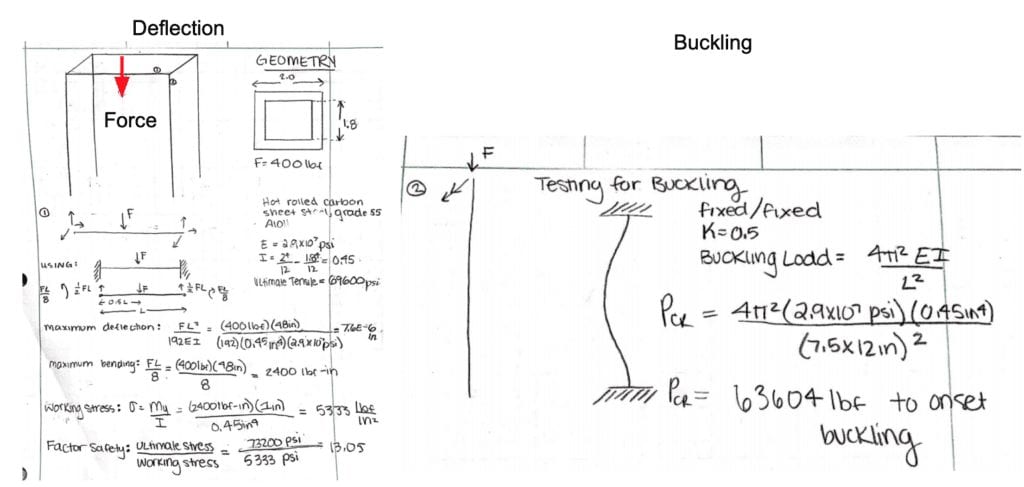

Design Analysis

Resistance Rack

Beam analysis was performed on the resistance band rack in order to determine the maximum load if someone were to hang off the top cross-beam.

Max Load: 500 lbf

- SF = 13.0

- Max Deflection = 7.6 E-6 in

- Failure @ 63,000 lbf

Punching Bag

- SF = 2.0

- Max Deflection = 0.23 in

Pedaler Attachment

The pedaler’s factor of safety and maximum loads were to be determined during testing by applying a load at the center of mass using a force gauge.

- Grade 5 Bolts Shear Failure @ 8000 lbf

- U-bracket strength to be determined during prototype testing

Manufacturing

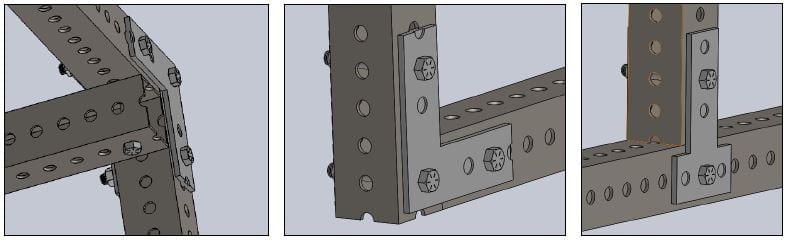

Resistance Band Rack

The resistance rack will be assembled together via the three connection methods shown above. The “L” and “T” brackets shown are made of 1/8″ galvanized steel and were donated by Home Depot and Lowes. They are connected to the frame with Grade 5 galvanized steel bolts, which are commonly used in automobile suspension systems.

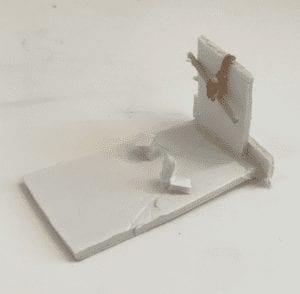

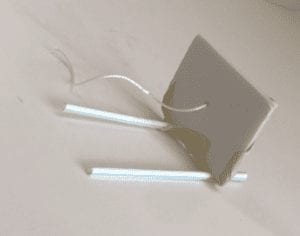

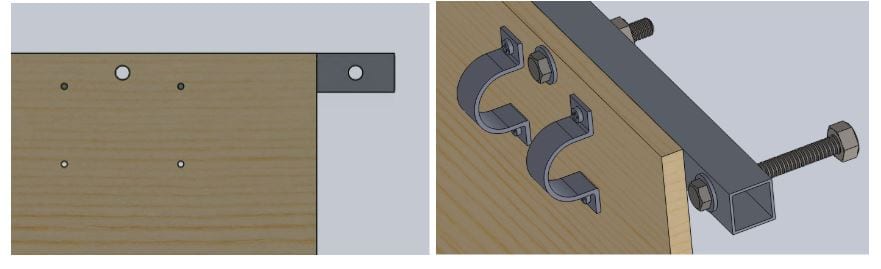

Punching Bag

To manufacture the punching bag attachment, bolt the 2 corner L-brackets to the top and bottom face of the 18″ perforated steel beam (shown in the left image). Then, attach the swivel mount and wooden platform to the other end of the steel beam. The speedbag can then be attached to the swivel mount.

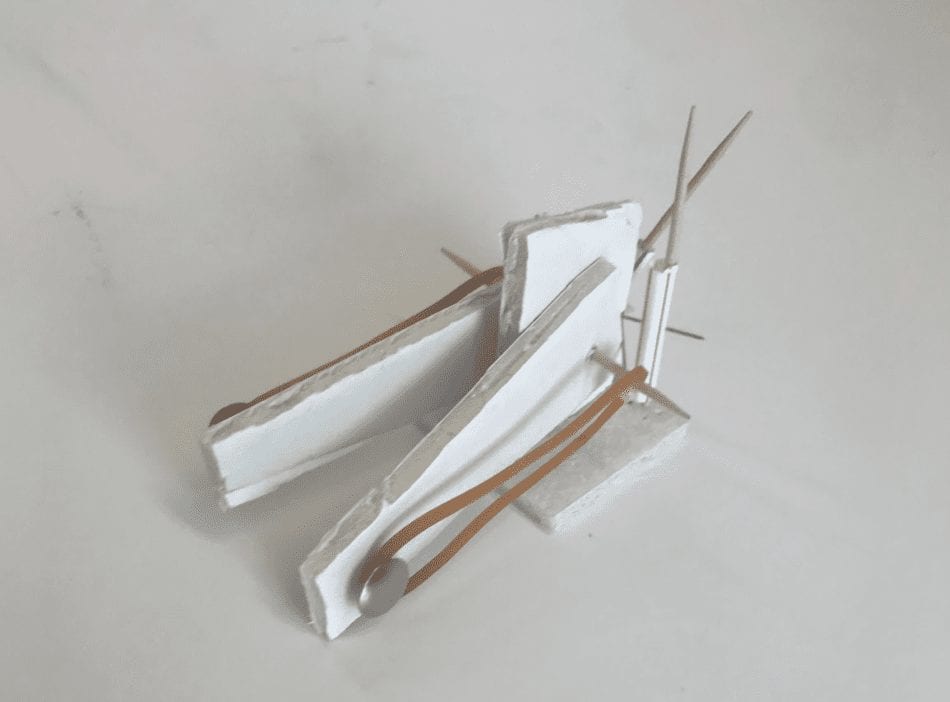

Pedaler Attachment

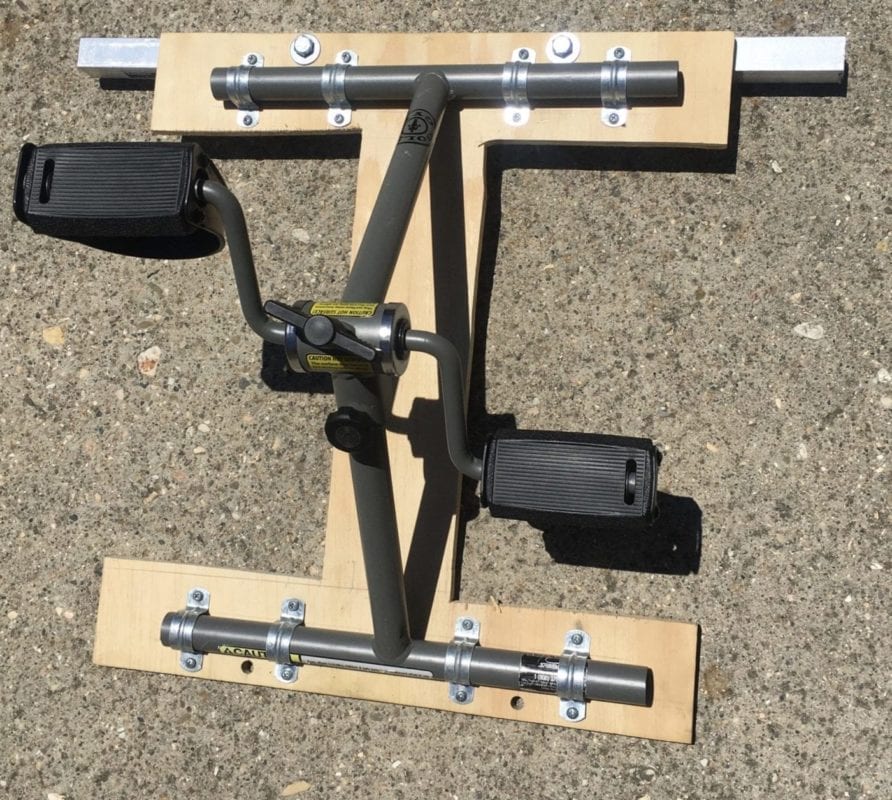

Once the appropriate holes have been drilled according to the pedaler engineering drawings, the aluminum square tubing can be bolted to the wood platform.

The pedaler can then be attached to the wood platform by clamping it with the U-brackets as shown above.

Testing Plans

Resistance Band Rack

Weight Test: Hang 200 lbs from center of top beams to simulate if a user were to hang on the resistance rack

Toppling Test: Apply a force at varying angles to the top beams of the rack and find the magnitudes that will cause the rack to tip over.

Punching Bag

Weight Test: Apply a weight to the end of the cantilever to simulate a user putting excess force on the top of the beam.

Impact test: Apply an impact horizontally to the end of the cantilever to ensure the attachment can withstand being bumped into.

Pedaler Attachment

Bracket Strength: Apply force to the pedaler once it is attached with the U-brackets. Find the magnitude of the force that will cause brackets to fail.

Recommendations

Improvements to be made if the exercise equipment were to be re-designed:

- More horizontal steel beams could be added to the resistance band rack to add more locations at which the bands can be connected.

- A higher quality pedaler would come equipped with a timer and also have longer durability than the purchased pedaler. However, the manner in which it is connected to the frame would have to be redesigned since the higher quality pedalers have different stands.

- Adjustable components could be redesigned with a pulley system instead of having to be unbolted and re-bolted.