The atmospheric water harvesting device is designed to collect liquid from moist humid air and condense it into viable drinking water.

This process is done with silica gels similar to what is seen in packets of dry goods. Once the gels become saturated with moisture, they are heated to the point where the water is condensed and collected.

Our Team

Meet the team that put together this senior project.

Adam Goldstein

Team Progress Manager

I am 4th year Mechanical Engineering Student. My interests in Mechanical Engineering include the thermal sciences and mechatronics. This project allowed me to gain deeper knowledge in the renewable energy field with the application of thermodynamics and heat transfer.

Scott Seno

Design/Test Manager

I am a 4th year Mechanical Engineering Student set to graduate in June 2020. I am interested in HVAC system design and thermal sciences. This project has given me an opportunity to make a change in an issue that affects people all over the world. Performing tests on this project allowed me to take a look at the real life applications of thermodynamics.

Kristen Dentici

CAD/Manufacturing manager

I am a fourth year Mechanical Engineering Student graduating at the end of this summer. On this team, my main function was manufacturing and analysis. I was in charge of CAD packages, manufacturing plans, and some of the analysis performed. This project was a unique and valuable experience and helped me expand my knowledge of thermo-fluids concepts that I had not encountered before.

Acknowledgements

We would like to thank our project sponsor, Rama Adajian, for his continued guidance and support throughout the design of the atmospheric water harvester. We would also like to thank our advisor, Sarah Harding for helping keep the project on track and for always lightening the mood.

Thank you to the following people for your support during the project: John Larson, Dr. Pascual, Everett Johnson, Kyle Kreitzman, and our ME 428-430 section.

Our Project Videos

Atmospheric Water Harvester

Problem Statement

Access to potable water is a global issue that has yet to be adequately solved. In regions with limited access to electricity and ground or surface water, it is not always possible to provide clean water through means that require external power or extensive infrastructure to implement. We are seeking to address these major issues by designing a water harvesting device that can be used in a wide variety of conditions at a low price point.

Design Constraints

- Collect 1/2 gallon of water per day

- Function off power from 1-2 solar panels

- Standard, metric parts when possible

- Cost less than $450

Design Description

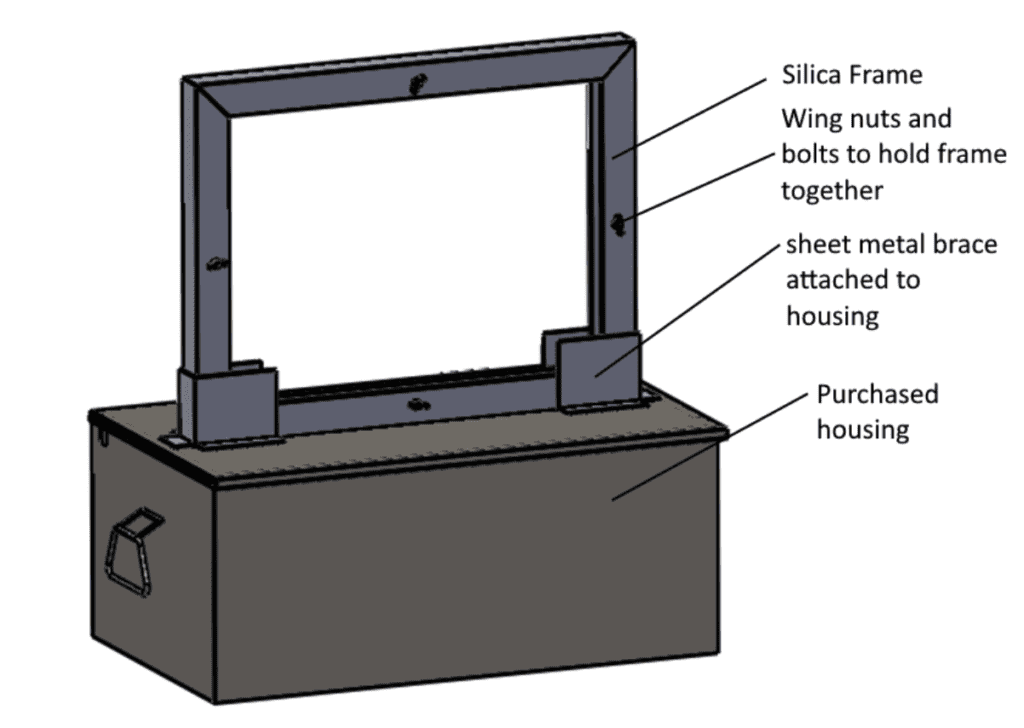

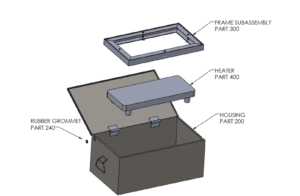

Our design features three main components: housing, silica gel frame, and heating. The silica gel collects water, then is heated to release the water to the air while the water is trapped inside of the housing.

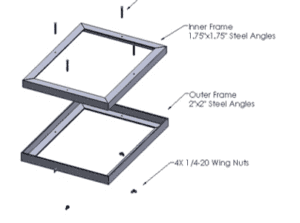

Silica frame to be manufactured out of 90 degree steel angle bars.

The frame consists of two parts in which one side of the frame slides into the other side of the frame similar to that of a gift box. The frame will then be bolted together which will allow for replacement of the silica gel when needed.

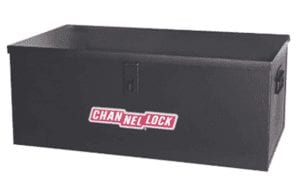

The heating box will holds the heating element as well as the silica frame when the system is in the heating and condensing phase. The heating box is based off of the dimensions for the frame. We used a Westward 13” x 31” x 18” welder’s box due to its large size and shape. This box is to be airtight to contain the evaporated water

Design Concept

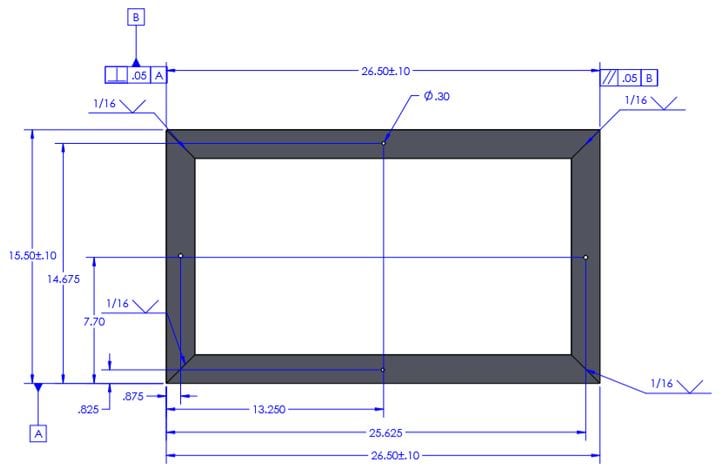

Silica Frame CAD Drawing

The main CAD component was the silica frame. The silica frame dimensions were used to size the housing as well as to determine hole placements for mounting the frame.

Team Sponsor

Rama Adajian

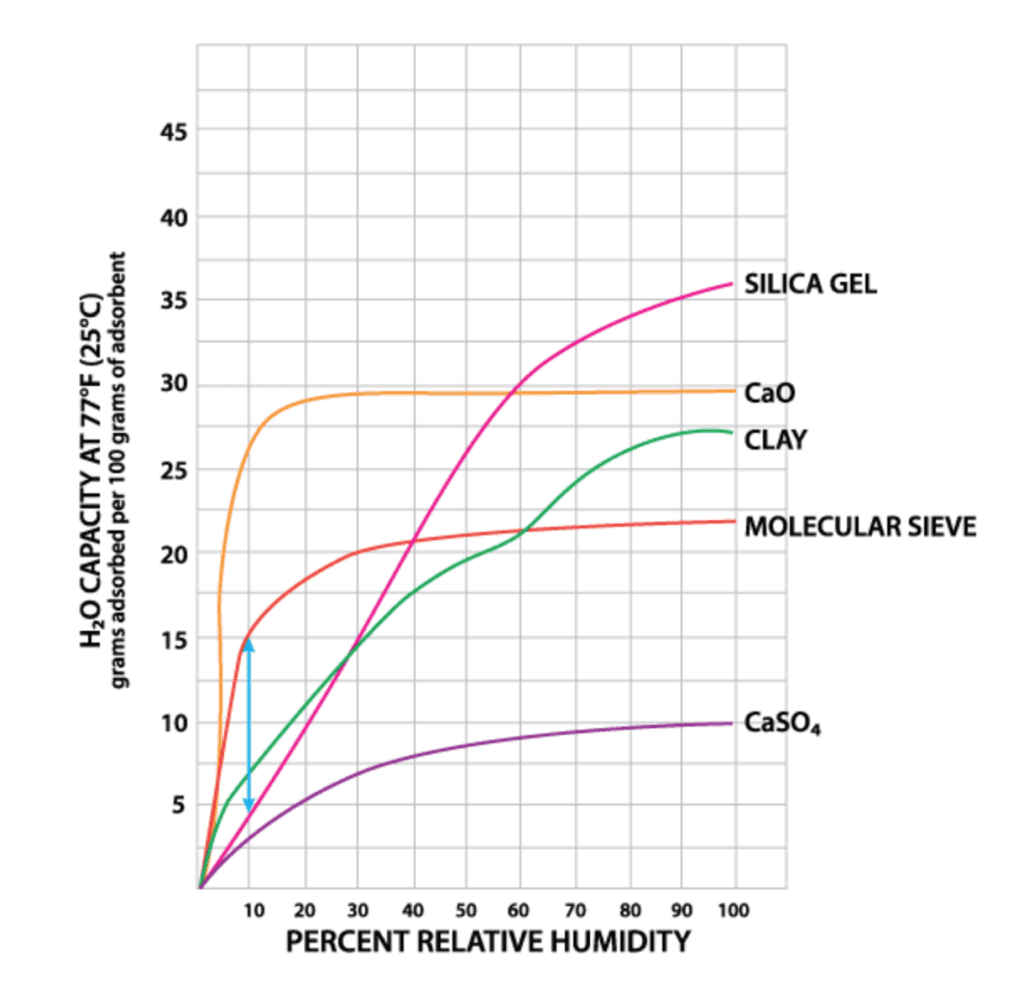

Desiccant Choice

Through mass and heat transfer analysis, it was determined that silica would be the optimal desiccant choice. This was based on it having a high H20 capacity relative to its volume. Additionally, it absorbs a significant amount of H20 in low humidity environments which other desiccants are less capable of.

Molecular Sieve was considered as well due to its ability to absorb significant amounts of moisture in low humidity environments. However, it is not nearly as readily available as silica gel and its consumption health effects are not as well known as silica gel.

Manufacturing Process and Components

Manufacturing was cut short due to Covid 19. The metal for the silica frame was cut to size, however it was never welded together.

Design Verification

Due to the Covid Pandemic, the only verification test we were able to complete was silica water absorption test.

Silica Absorption Test:

- Silica gel was left out overnight near a window and reheated the next morning.

- ~3 lbs of silica were heated for 1 hour at 250 °F.

- Tests estimate ~1/4 gal of water extrapolating data to 30 lbs silica.

Final Design

Specifications

Silica Weight: 30 lb

Dimensions 13″ X 31″ X 18″

Custom Components

- Silica Frame

- Mounting Brackets

Stock Components

- Housing (Heating box)

- Silica Gels

- Heater

- Aluminum Mesh

- Sealant

- Gaskets/Grommet

- Fasteners

Future Application

Due to Covid 19, this project was not able to be completely manufactured as originally planned. Once expo is complete, all of the parts of this project will be sent off to our sponsor where he will complete the manufacturing and assembly of this project on his own time.

Due to Covid 19, this project was not able to be completely manufactured as originally planned. Once expo is complete, all of the parts of this project will be sent off to our sponsor where he will complete the manufacturing and assembly of this project on his own time.

Ultimately, a complete functioning prototype will be generated to reliably generate half a gallon of water a day for an individual.

Recommendations

We recommend the following improvements/testing:

- Full scale (30 lb of silica) test

- Heating power test

- Housing seal test

- Implement multiple types of dessicant

- Improve heat source

- Design water collection area

- Automate water scraping and collection