Meet the Mechani-Kids

We are all graduating seniors who loved making these kits this year.

sophie carson

statics Kit Lead

Sophie is graduating this spring with a degree in Mechanical Engineering. She has led the design and manufacturing of the Statics MechaniKit throughout Senior Project. After graduation, she is moving to Seattle to begin a career with Stryker as a Quality Engineer.

Vincent Seguin

Dynamics kit Lead

Vincent is graduating from Cal Poly this spring. He led the design, manufacturing and in-class tests of the Dynamics MechaniKit throughout Senior Project. After graduation, he will be moving back to his parents’ house.

Jake Utley

Physics Kit Lead

Jake is graduating from Cal Poly this Spring. During Senior Project he led the design and manufacturing of the Physics Kits. After college he will be moving to Seattle to start his career as a Project Manager for Microsoft .

Acknowledgements

This project would not have been possible without the help of our Senior Project Advisor Peter Schuster, and our sponsors at Cal Poly: Dr. Vokos, Dr. Moelter, Dr. Chen, and Dr. Self. We received funding for this project through the Mechanics of Inclusion and Inclusivity in Mechanics grant, a grant aimed at improving educational outcomes for students from diverse backgrounds. We would also like to thank the entire ME Department for all of their help throughout our academic careers!

Our Project Videos

MECHANIKIDS' SENIOR DESIGN PROJECT

Problem Statement

The purpose of the MechaniKits senior project was to create hands-on, supplemental materials to enhance student learning in Cal Poly mechanics courses to help satisfy student learning needs in General Physics, Statics, and Dynamics.

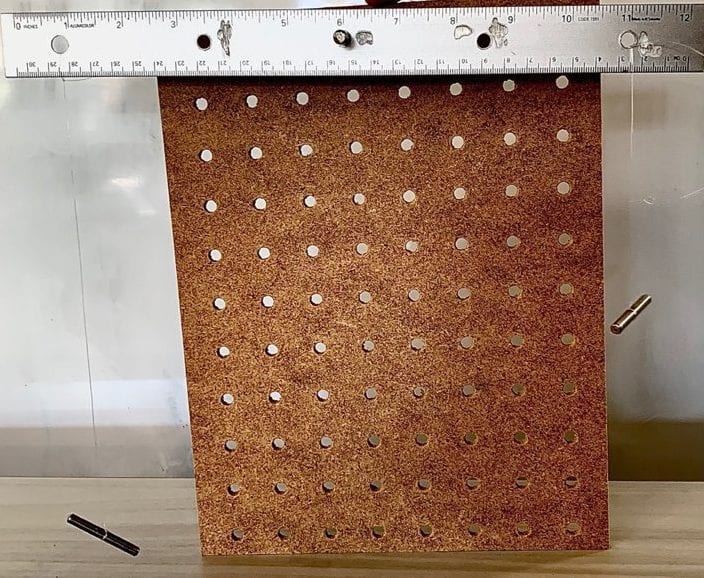

Design Constraints

- Cost less than $50 per Kit

- Maintain component functionality through 3 quarters of use

- Retain functionality after a 6 ft drop test

- Contain zero toxic materials

- Function properly 95% of the time

- Increase student understanding with an effect size of .2

- Allow activity assembly in less than 5 minutes

- Weight less than 5 lbs / kit

- Ensure all kits support at least 3 activities

- Create separate customizable kits for Physics, Statics, and Dynamics

- Have a minimum student satisfaction of 75% for every activity

- Ensure all kits can fit in a backpack

Prototype Kit Activites

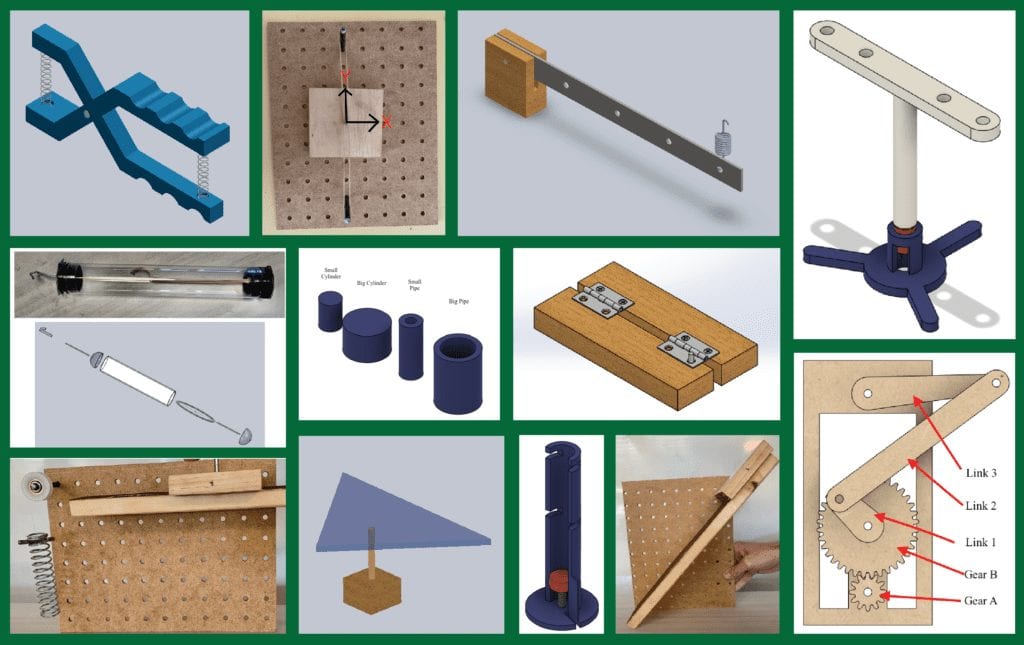

Concept Prototype Phase

- Our project involved extensive prototyping in the Fall and Winter Quarters

- In total we designed, manufactured and tested 20 prototypes to ensure our kits had activity designs that worked and aided student understanding

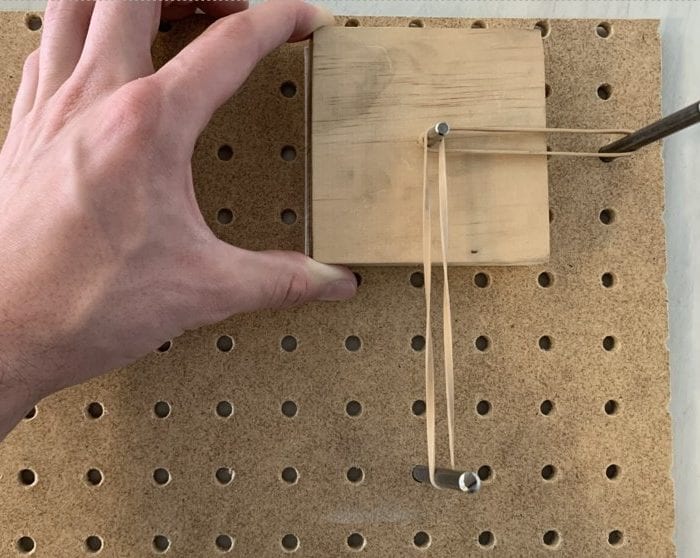

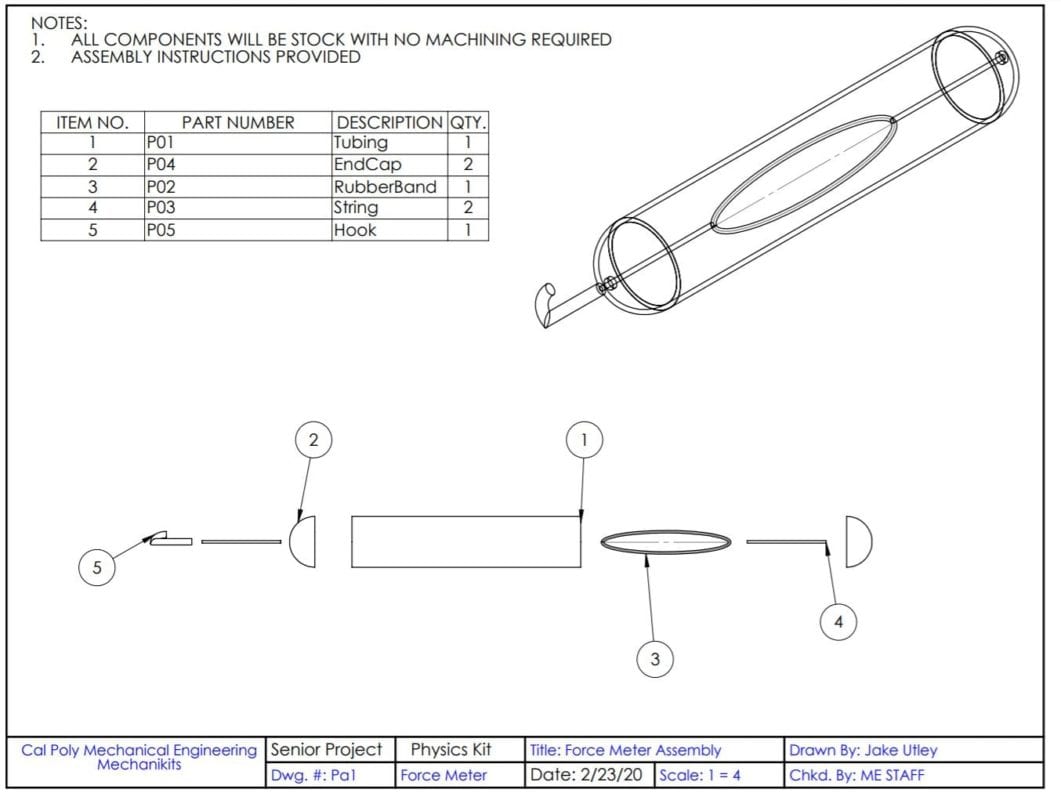

Physics Concept Prototypes:

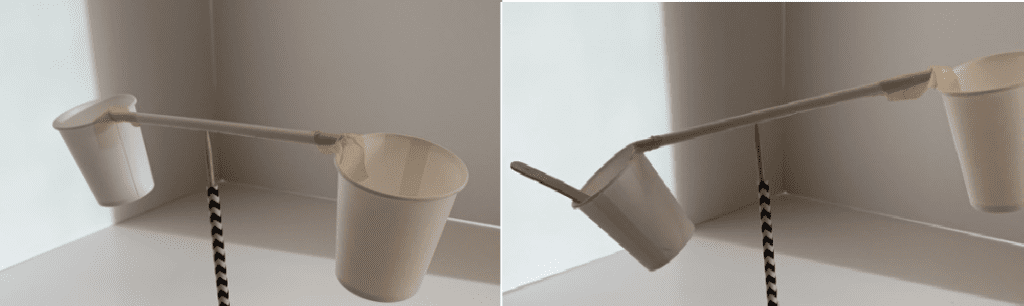

- Movable Pivot Balance

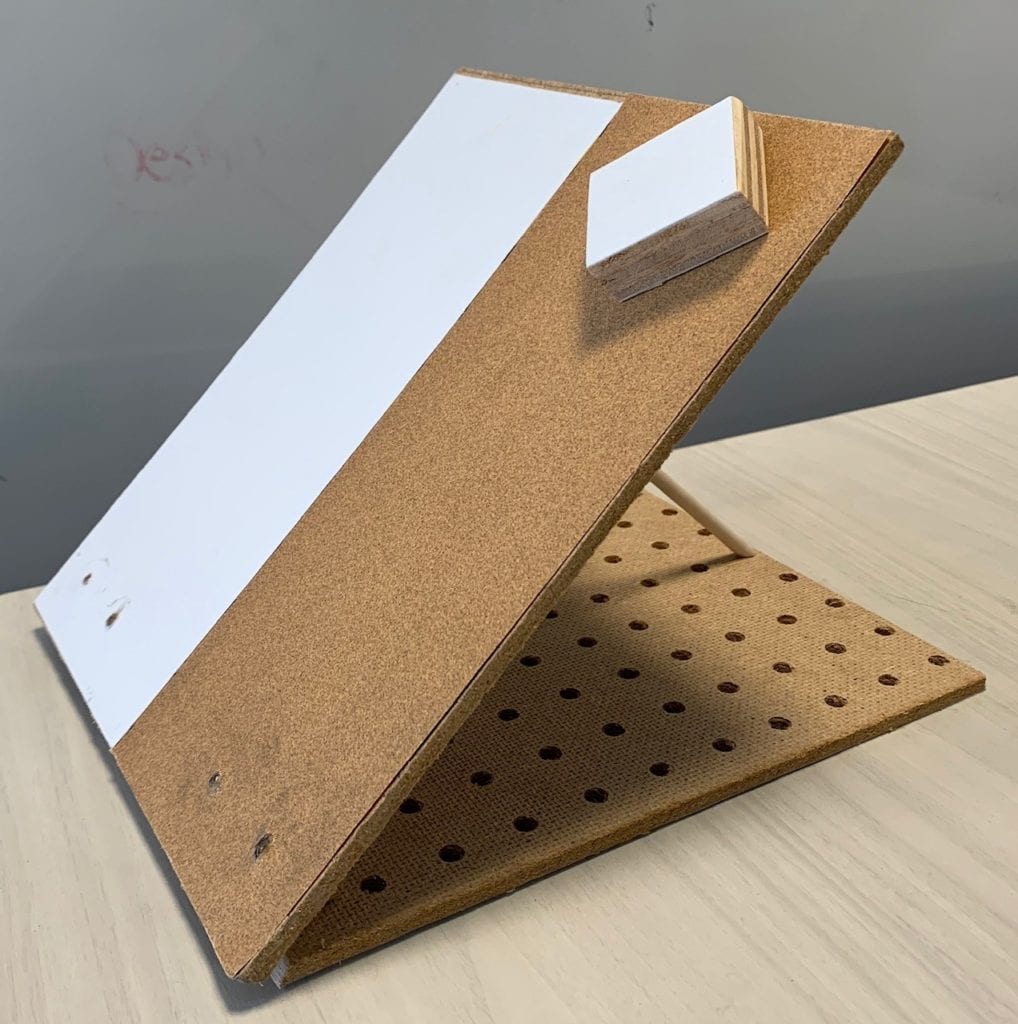

- Block and Ramp

- Simple Atwood Machine

- Ramp Atwood Machine

- Static Friction Ramp Activity

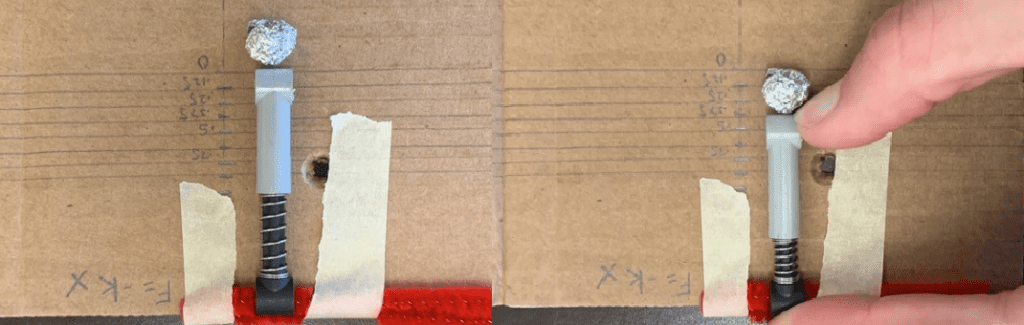

- Force Meter

- Vector Demonstrator

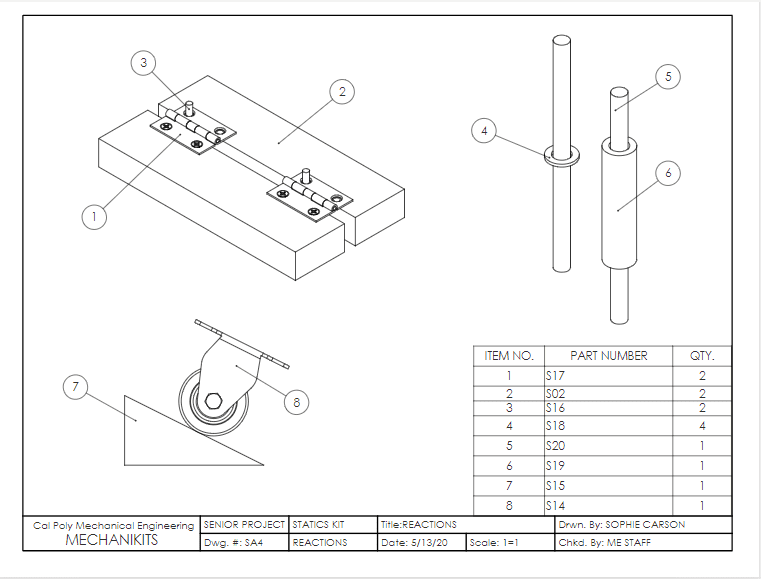

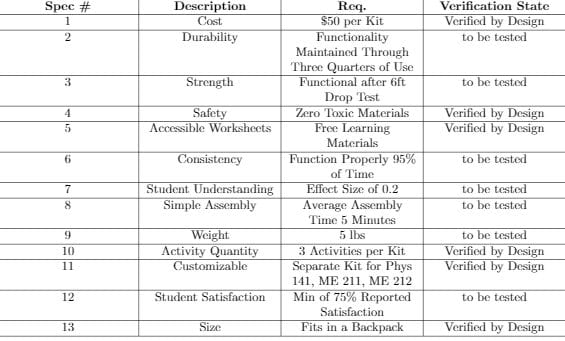

Statics Concept Prototypes:

- Identify Centroids

- Remove Zero Force Member

- Force Component Detection on an Inclined Plane

- Force to Balance Torque

- Max Static Friction

- Machine Force

- Identify Reactions

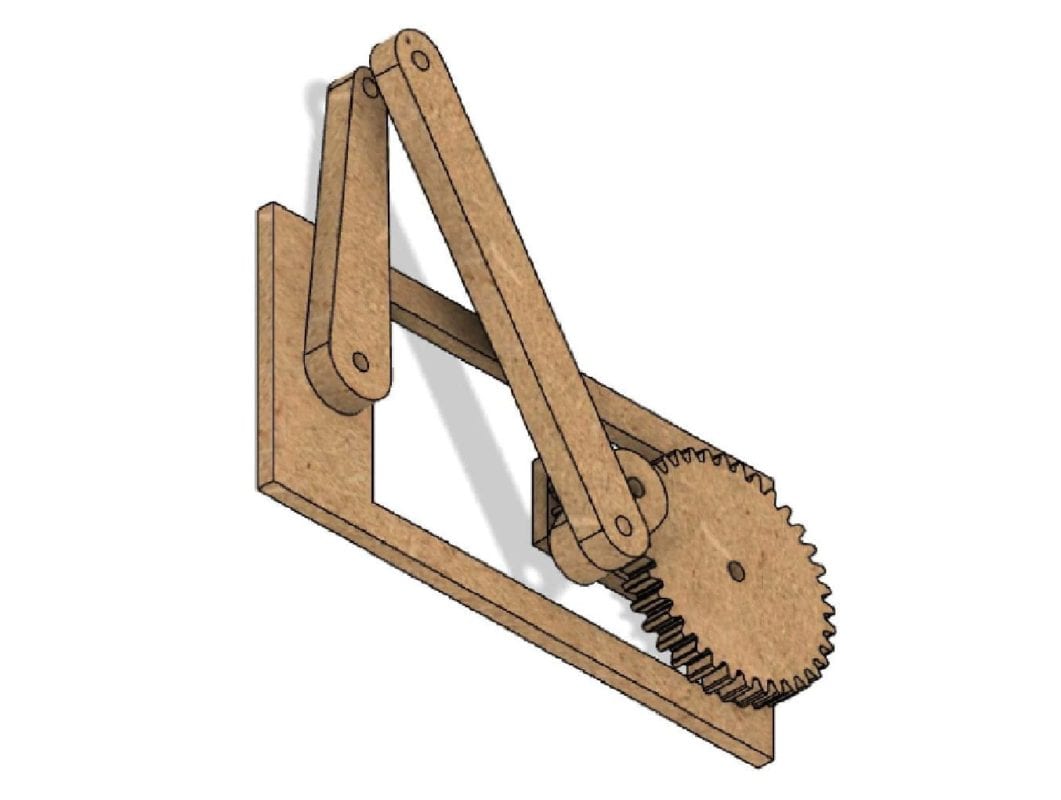

Dynamics Concept Prototypes:

- Coriolis Acceleration

- Mass Moment of Inertia

- Cycloid Motion

- Rigid Body Kinematics

- Spinner

- Impact

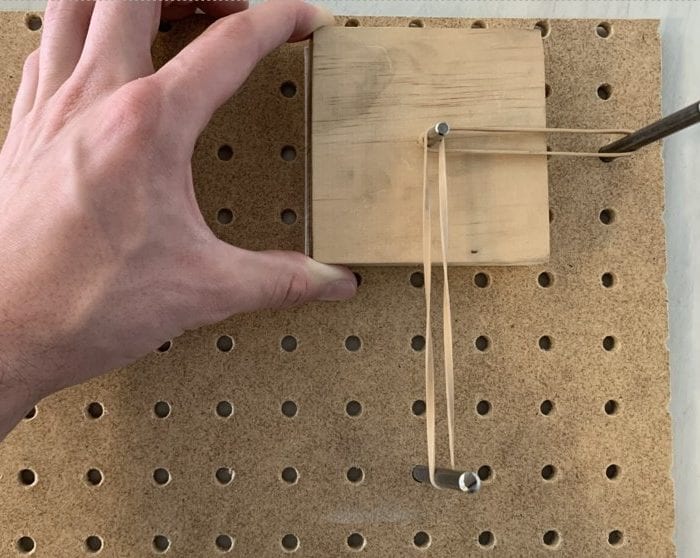

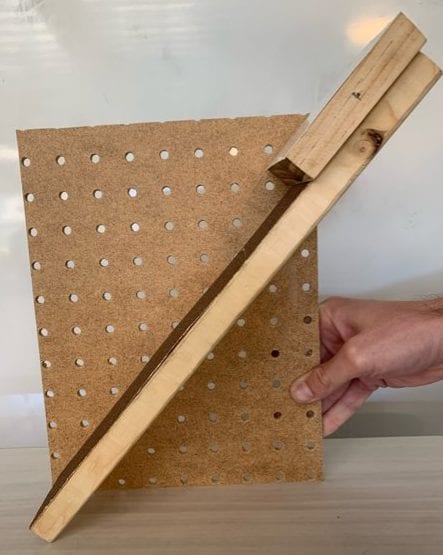

Design Verification Prototypes

Our peers tested each prototype and activity. We used these results to improve our design and incorporated their feedback to create interactive worksheets for each final activity.

Our peers used our “Post Activity Survey” to review prototypes by rating activities from 1 (“strongly disagree”) to 5 (“strongly agree”) for each of the following criteria:

- This activity improved my understanding

- The equipment provided was easy to set up

- This activity led to the expected outcome

- This activity would be beneficial to students

- I enjoyed participating in this activity

Manufacturing Plans

Due to the campus closure, we were not able to manufacture 10 sets of each kit to test in Cal Poly classes. Instead, we are providing the Cal Poly Machine Shops with detailed manufacturing plans to enable our sponsors to have kits produced when campus reopens.

Design Verification

Some requirements were verified through design, but most require in-class testing for evaluation.

Current activity designs can be used for verification testing, though there is room for improvement and optimization.

Verified through Design

- Kit Costs: Each kit costs less than $40 to manufacture

- Safety: All manufactured parts made out of wood, MDF, or PLA

- Free Learning Materials: Supplemental worksheets provided for each kit

- Number of Activities: 4 to 5 planned activities per kit

- Weight: Average weight of kit is 3.75 lbs

- Customizable: Manipulatives and activities used or modified at instructors’ discretion.

- Size: Kits can fit in a backpack with no component larger in size than a sheet of paper

To be Tested

- Durability: Assess functionality after in-class activities

- Strength: Assess functionality after 6 ft drop test

- Consistency: Assess functionality during in-class activities

- Student Understanding: Analyze student responses from surveys

- Student Assembly Time: Time demonstration and first-time use

- Satisfaction: Analyze student responses from surveys

Final Kit Design

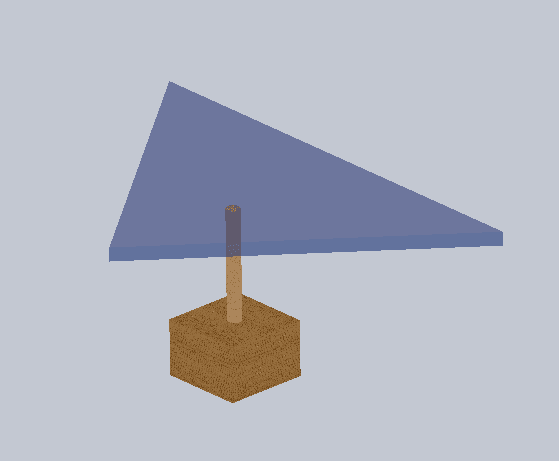

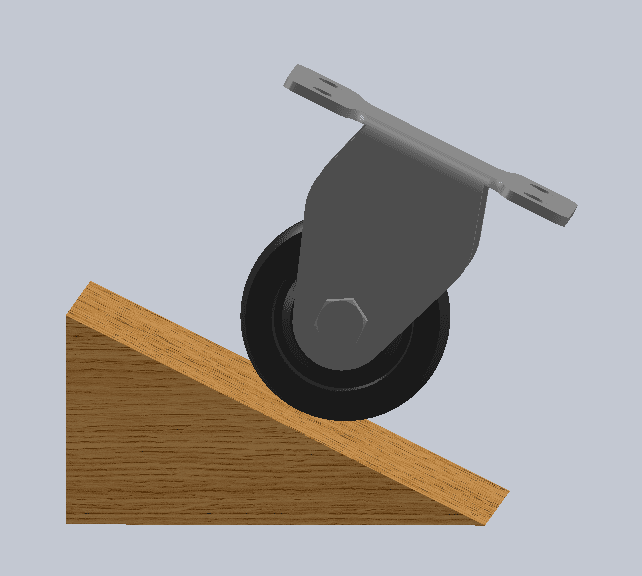

Physics

- $29.00 per Kit in Material Cost

- Concepts Covered:

- Vectors

- Kinetic Friction

- Free Body Diagrams

- Torque

- Static Equilibrium

- Hooke’s Law

- Tension

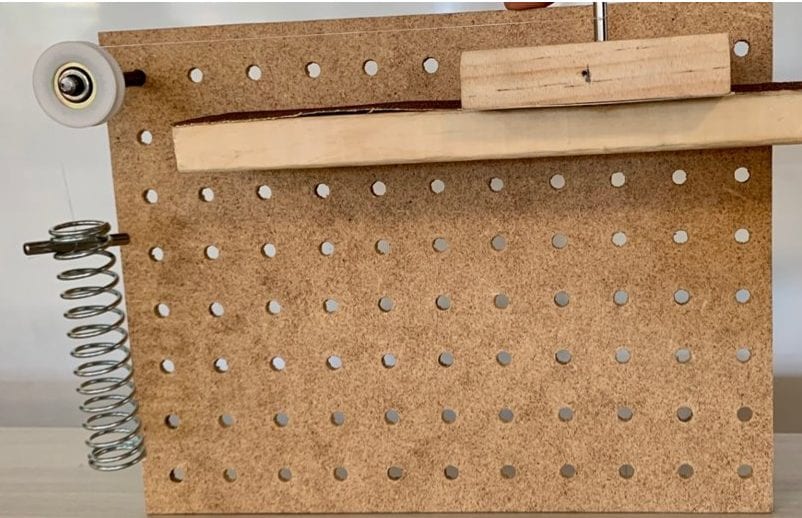

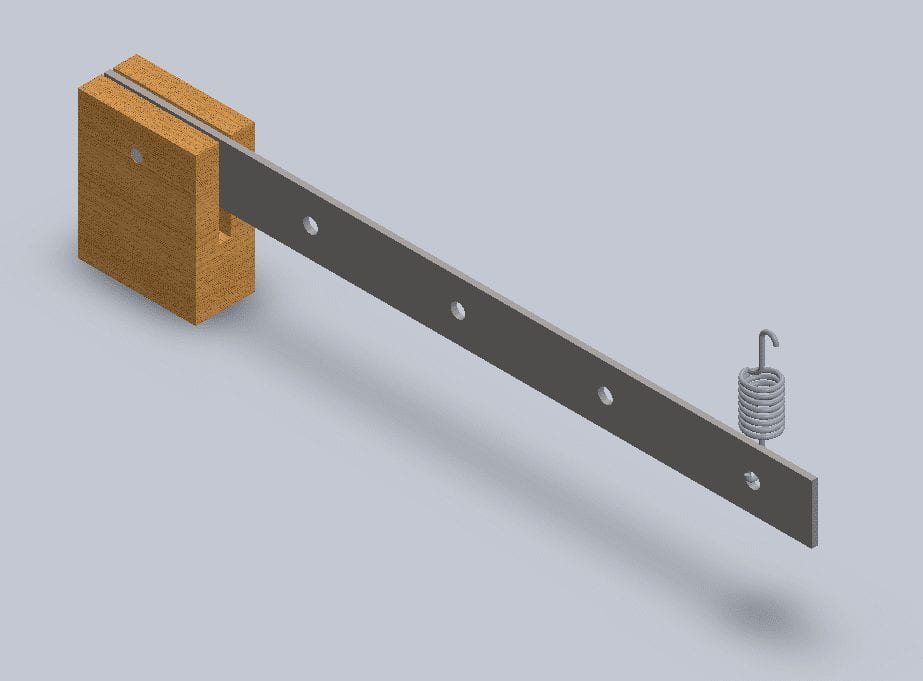

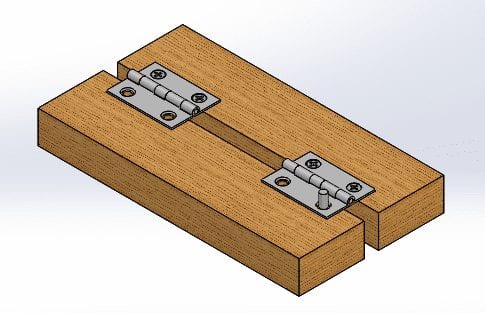

Engineering Statics

- $18.80 per kit in materials costs

- Concepts Covered:

- Reactions Forces, Force Couples

- Torque/Moments

- Static Equilibrium

- Simple Machines, Mechanical Advantage

- Indeterminate Systems

- Centroids, Center of Mass, Parallel Axis Theorem

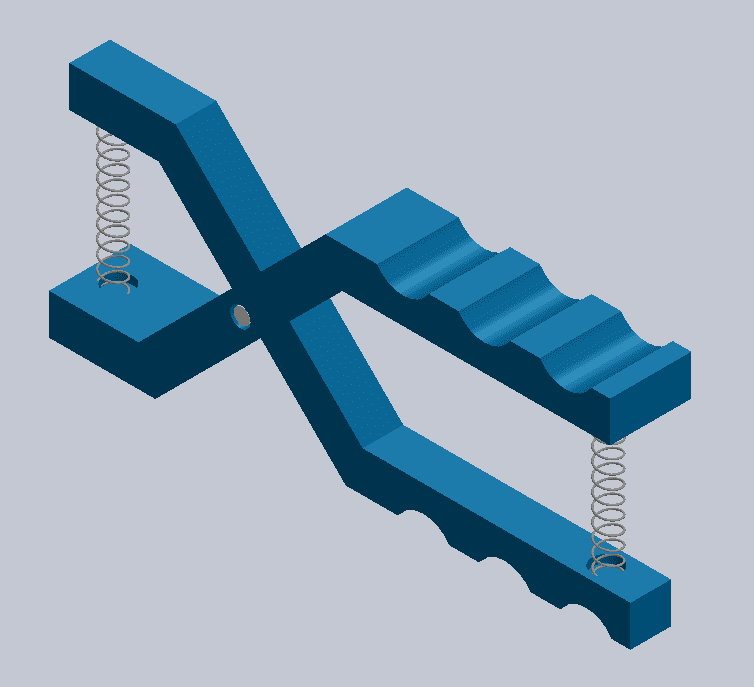

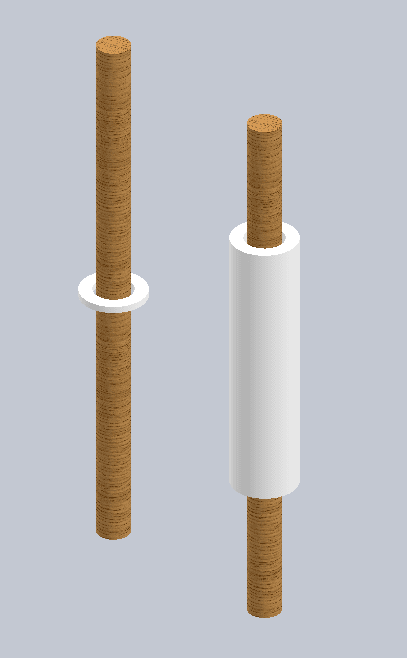

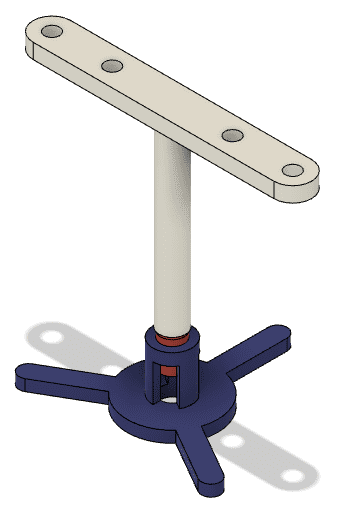

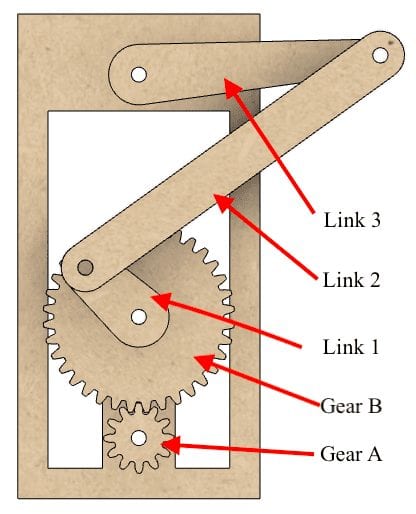

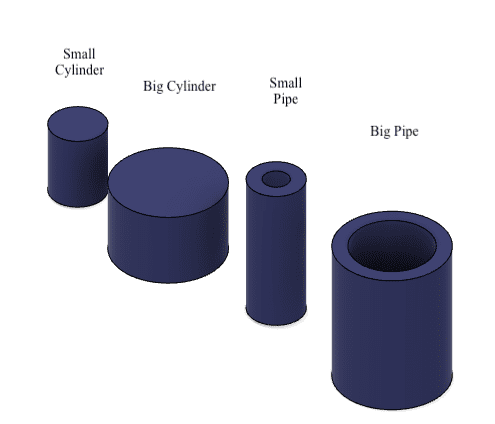

Dynamics

- $20 per kit in materials cost

- Concepts Covered:

- Impact

- Swing Ride

- Mass Moment of Inertia

- Linkages

Future Applications

When campus reopens, our faculty advisors plan to have ten sets of each kit manufactured. The activities, worksheets, and instructor guides will be utilized in Cal Poly courses to enhance student learning.

Recommendations

- Conduct additional testing to assess the effectiveness of all activities

- Seek student feedback to improve designs

- Consider alternative materials sourcing if more than 10 kits are to be produced