Our Team

Camaryn chambers

I am a general concentration fourth-year mechanical engineering student, but I am interested in aerospace. Last summer I interned at Aerojet Rocketdyne in LA, but I am from Hood River, Oregon. I worked in Mechanical Design at Aerojet. I am also involved in SWE and Tau Beta Pi on campus. In my free time I like to go to the beach, watch movies, and play tennis.

Callen schwefler

I am a fourth-year mechanical engineer with interests in astronomy, additive manufacturing, nuclear engineering, and thermofluids. I spent my summer interning with Lawrence Livermore National Lab on a research project for the Global Security directorate. I am curiosity driven and interested in a research-oriented career.

Joel Pitzer

I am a fourth-year mechanical engineering student. This summer I interned at Aerojet Rocketdyne as an Electromechanical Packaging Designer. I am interested in mechatronics and mechanical design and hope to work in the aerospace industry. I like to play sports (especially soccer and volleyball), go camping and hiking, and go snowboarding.

Matthew allen

I am a fourth-year mechanical engineering student, concentrating in mechatronics. I have an interest in robotics and manufacturing, I would like to work in the aerospace industry. I am part of the hyperloop club on campus where I am working to design a composite chassis for this year’s iteration of our pod. In my free time I like to work out, play soccer, and catch up on sleep!

Acknowledgements

We would like to thank our senior project advisor, Dr. Eltahry Elghandour and our project sponsor, Brian Harding from the Berkeley Space Sciences Laboratory. This project would not have been possible without their dedication and hard work.

We also want to thank Kodi Rider, a former Cal Poly graduate currently working at Berkeley SSL, for his help and advice on the project.

We would like to acknowledge our funding by NSF AGS-1933077.

Our Project's Digital Poster

Problem Statement

The research scientists at the Space Sciences Laboratory need a way to remotely change between four optical filters over a telescope. The device must be stable over expected temperature extremes and other disturbances. The device must also be cost effective, robust, and easily attach to their current equipment.

Design Constraints

- Fit in 254 x2 54 x 203.2 mm box

- Tilt filters 1-10 deg (0.2 deg steps)

- Center active filter 127 mm from x and y edges

- Last 200,000 cycles between maintenance

- Cost under $4000 after prototype

- Maintain temperature within ±2.5°C

Filter Selector Layout

A filter wheel was chosen for the following reasons:

- Well studied and validated method for switching between separate filters

- Balanced simplicity of design with the space constraints given

Other design choices to note:

- Use of a smart motor to spin the filter wheel

- Implementation of a thermal enclosure with heating pads to provide thermal stability for the system (the filters are temperature sensitive)

- Material choice of Aluminum 6061: this was chosen to reduce the weight of the system and increase the strength of the system

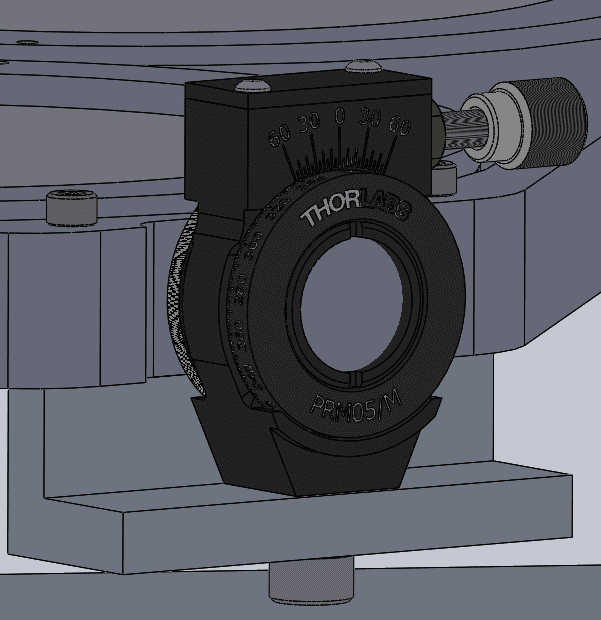

- A PRM05 was selected to accurately measure the angular changes of each filter so they could be properly set up and secured

The PRM05 device that was selected for precision angular measurements. This will be used to tilt the filter and refine the wavelengths of light coming through the filter.

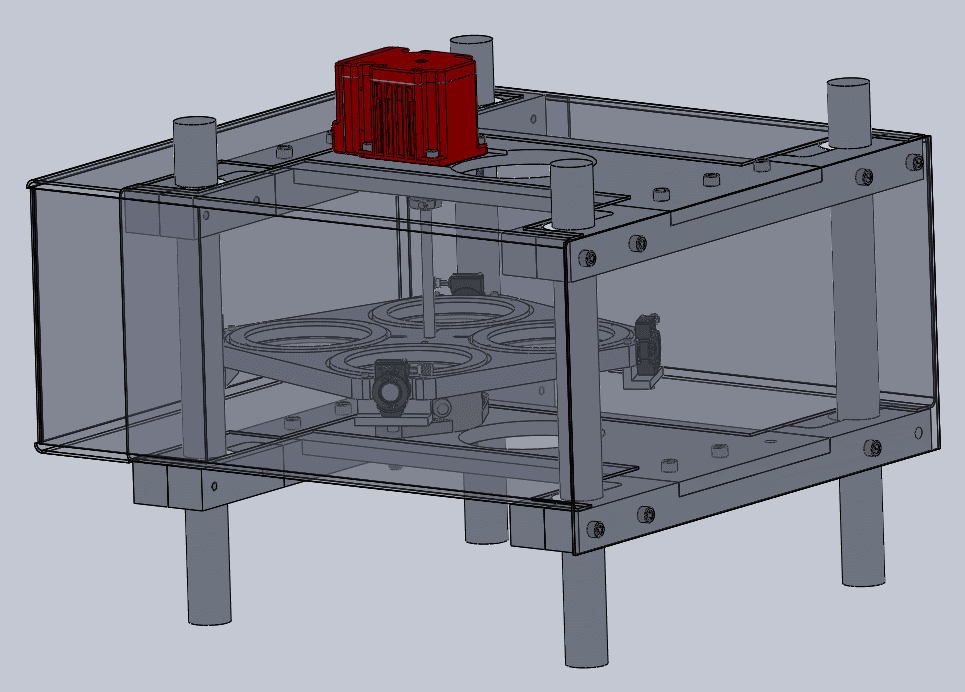

The thermal enclosure is necessary to ensure temperature stability of the system. The aluminum walls will have heating pads attached to concentrate heat inward raising the system temperature to a steady desired temperature.

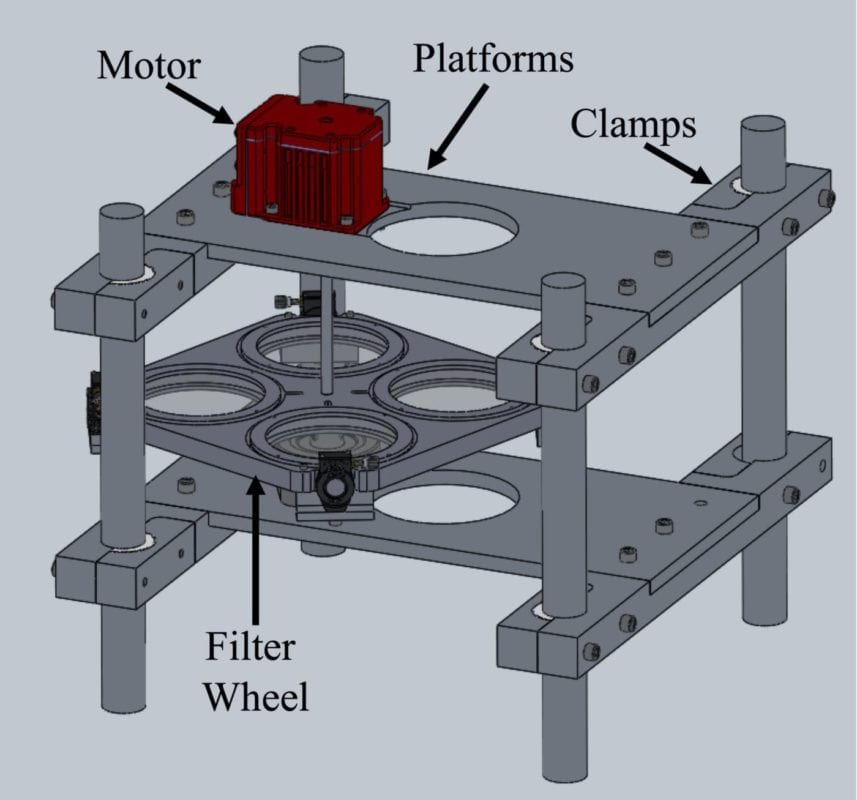

Design Concept

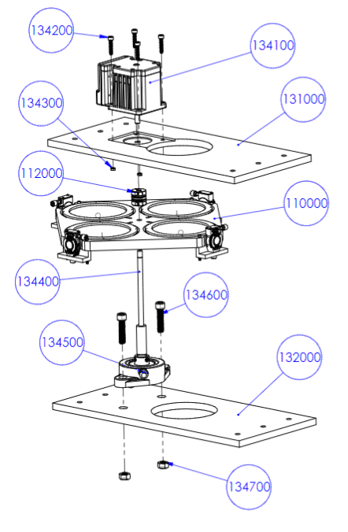

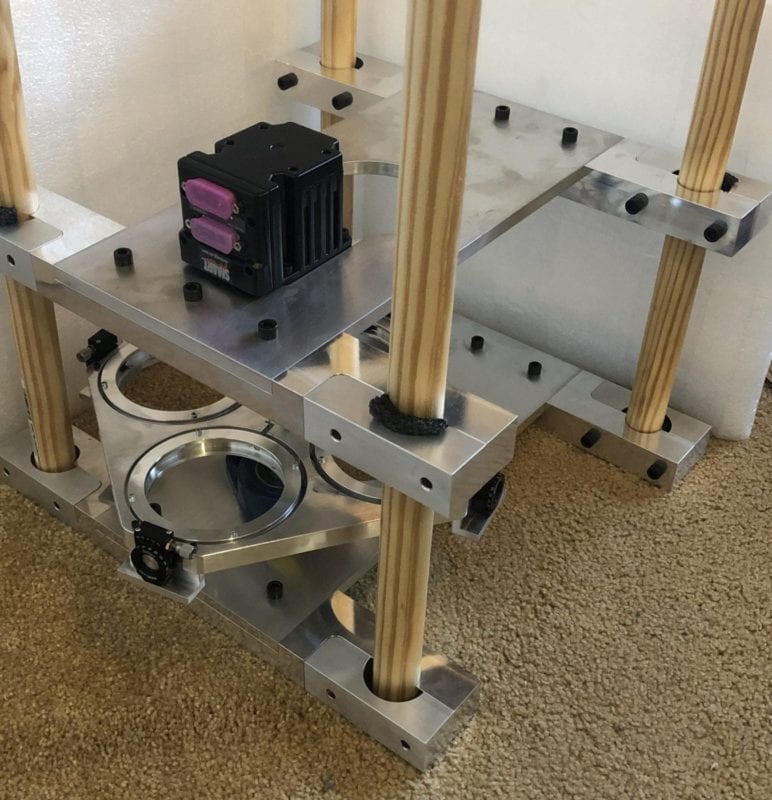

CAD model for the filter selector with selected subassemblies called out.

Exploded view to show all components included in the filter selector assembly.

The CAD model allowed for design verification and analysis. By ensuring the CAD model worked in the virtual environment, it was easier to transition to the manufacturing stage.

Berkeley SSL & Cal poly

This project is sponsored by Brian Harding at the Berkeley Space Sciences Laboratory and Dr. Eltahry Elghandour with the Cal Poly Mechanical Engineering Department.

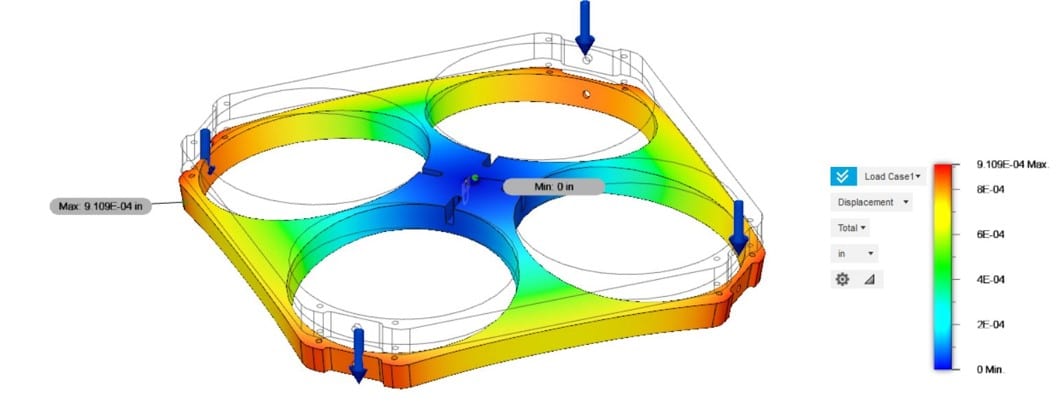

Filter Selector Analysis

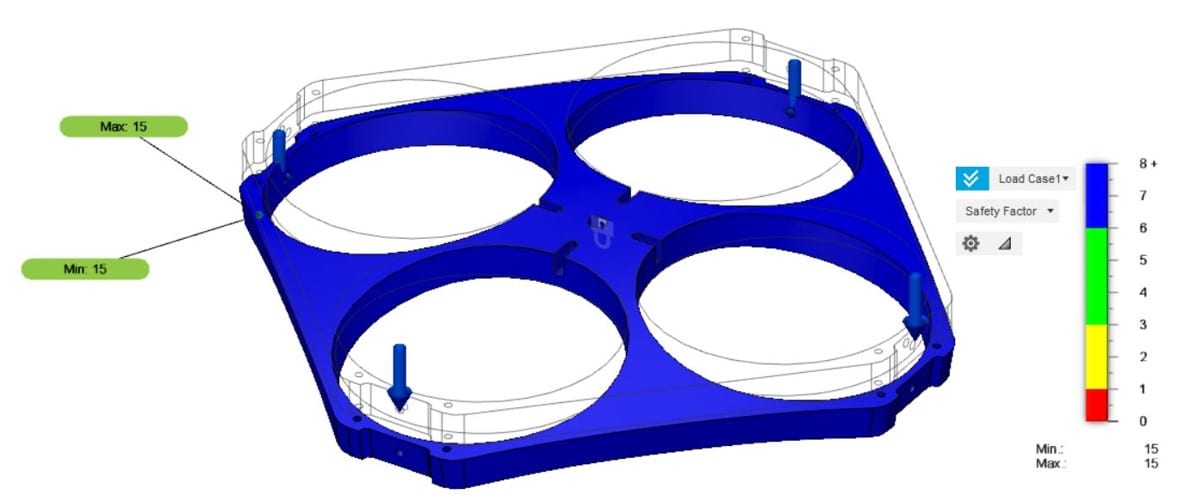

Simple FEA case showing deflection of the filter wheel with a load that is 10 times the anticipated load. The deflection was confirmed to be of minimal concern.

Simple FEA case showing the factor of safety for the filter wheel with a load that is 10 times the anticipated load. The deflection was confirmed to be of minimal concern.

Simple FEA case showing the factor of safety for the filter wheel with a load that is 10 times the anticipated load. The deflection was confirmed to be of minimal concern.

Through analysis, we were able to determine that the design we had developed would not deflect out of tolerance or break due to the rotation of the system. Basic analysis was done of the thermal stability of the system, but it was largely decided to study this effect empirically.

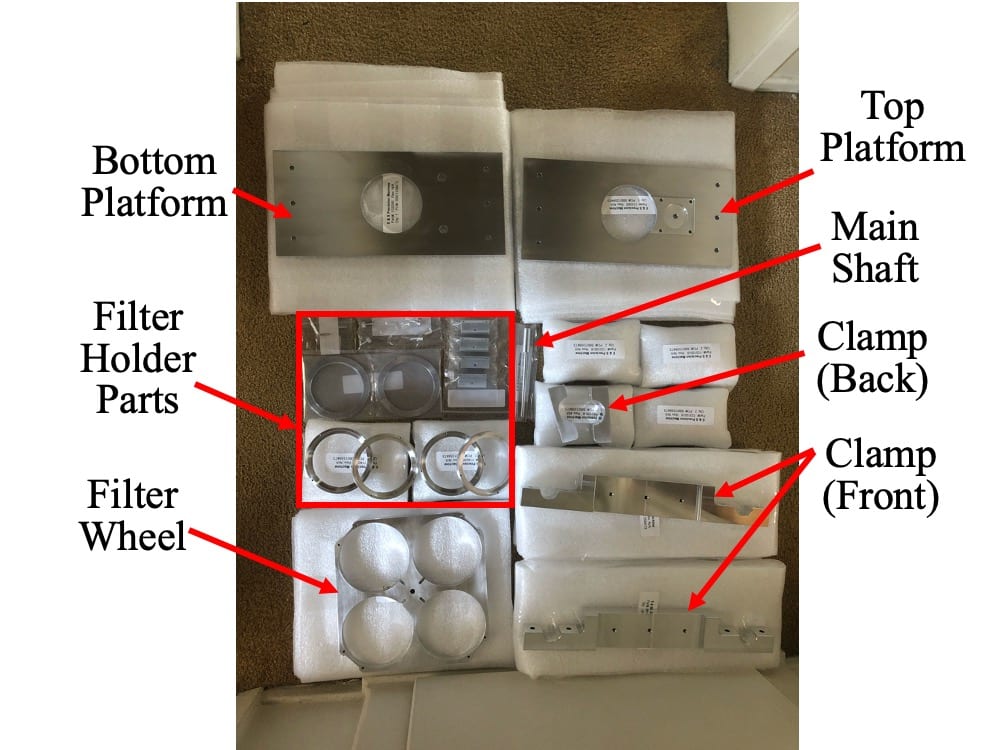

Manufacturing Process and Components

Due to the complexity and tight tolerances of our parts, it was determined it would be best to have a machine shop perform the manufacturing based on our drawings.

Design Verification

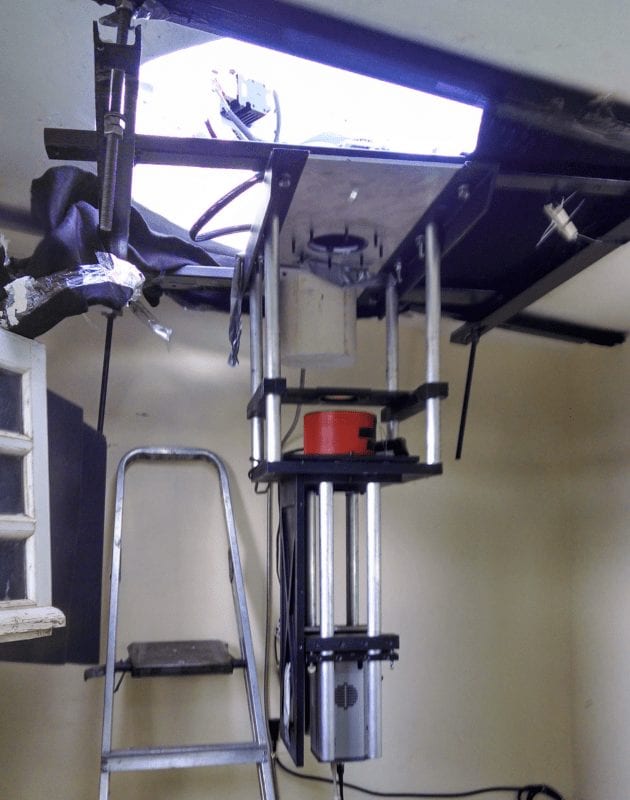

We built the thermal test stand that held the prototype of the thermal enclosure. Insulation was applied over the heating pads and the temperature inside the enclosure would be monitored.

Thermal Test- For this test, we set up the thermal enclosure on our testing stand and turned on the heating pads. If the temperature fluctuated too much, a different design would need to be pursued. We were unable to complete this test since our insulation started to melt.

Life Test- Our design would be verified by testing the design for 200,000 cycles to verify that it would not shift the filter positions or tilt out of tolerance. Since our last quarter was virtual, we could not perform this test, but we did provide testing instructions.

System Interface Test- This fairly straightforward test verifies that the design fits together, can rotate without interference, and that the clamps do not slide down the poles over time. The parts passed our fit test.

Final Design

Custom Components

- Filter Wheel

- Clamps

- Platforms

- Filter Holders

- PRM Bracket

- Shafts

Stock Components

- PRM05

- Screws

- Bolts

- Filters

- SmartMotor

- Bearing

- Shaft Coupling

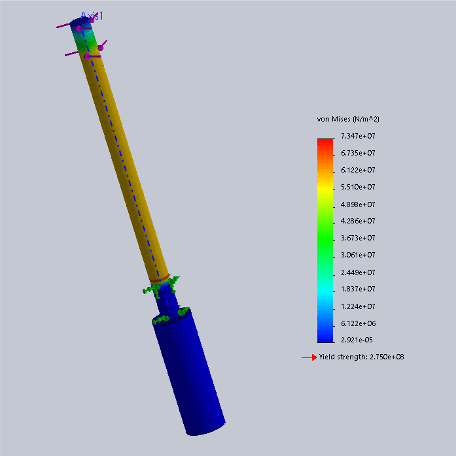

Additional Analysis

Since we were unable to complete the life test, we performed additional analysis to verify the system. We used SolidWorks FEA to simulate the most probable cause of failure, if the filter wheel got stuck and the motor torque increased. This could potentially cause the main shaft to fracture, but our analysis proved that the system was safe.

Future Application

The Berkeley Space Sciences Laboratory will be using this design in order to measure properties of the airglow in order to infer properties of the upper atmosphere. The final design will be placed into their current instrumentation so that they can observe multiple wavelengths of light, which they have not been able to do before.

The filter selector will be used in their current instrumentation to replace the single filter that they would use.

A recent deployment of their instrument, a Fabry-Perot interferometer deployed in Morocco.

Photo credit: University of Illinois

Recommendations

Improvements to be made if filter selector were to be re-designed:

- Complete thermal test and life test

- Find an alternate way to tilt and secure the filters that reduces costs

- Find a way to use one PRM05 for the four filters

- Manufacture the parts in the Berkeley machine shops

- Add thermal enclosure that minimizes holes and creates a window in the enclosure to allow access to the active filter

- Simplify the filter holder

- Loosen some tolerances to reduce costs and machine time

- Determine the best insulation to place around the thermal enclosure

Our Project Videos

This video shows a general overview of the project. It includes an introduction to the team, a description of the need for the project, and a discussion of the final design.

This video provides more detail on the technical aspects of the project. It details the design process, the final prototype, and the analysis performed.