Our Team

Chris chen

Hardware and management lead

- Kept track of the team’s timeline and progress

- Researched and selected components to meet design requirements

kara hewson

software and design lead

- Created the CAD model of our system

- Developed and wrote code for our GUI

joel keddie

testing and safety lead

- Performed Risk Assessment and Failure Mode Effect Analysis

- Wrote Testing Procedures

kayla collins

manufacturing and budget lead

- Manufactured all custom components

- Assembled the device

- Kept track of costs for each component

Acknowledgements

Our team would like to thank our lab instructor Dr. Peter Schuster for supporting us throughout this project. We would also like to thank Dr. Richard Emberley for his sponsorship and guidance throughout the year.

Our Project Videos

Our Project's Digital Poster

Problem Statement

Design and build a portable calorimeter for use in the Combustion Lab at Cal Poly and out in the field. The device must show how the heat release rate of a burning substance changes over time.

Design Constraints

- Must be portable

- Must accurately output heat release rate of burning substance

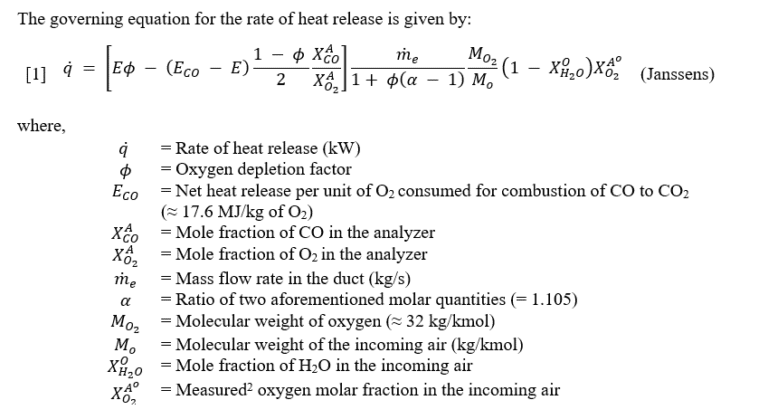

Background

Design Concept and Process

Similar existing products were researched and the major necessary components were determined to be:

- CO, CO2, O2 sensors for detecting concentrations

- Pump for directing smoke from exhaust duct to sensors

- Power supply for sensors and pump

- Graphical user interface for collecting data

- Aspect of portability/containment of components

These components were sourced with size, cost, and quality in mind.

Portable Calorimeter for Fire Experiments

May 2020

Final Design

Specifications

Weight – 12 lbs

Dimensions – 18″ x 14″ x 6″

Total Cost – $1355

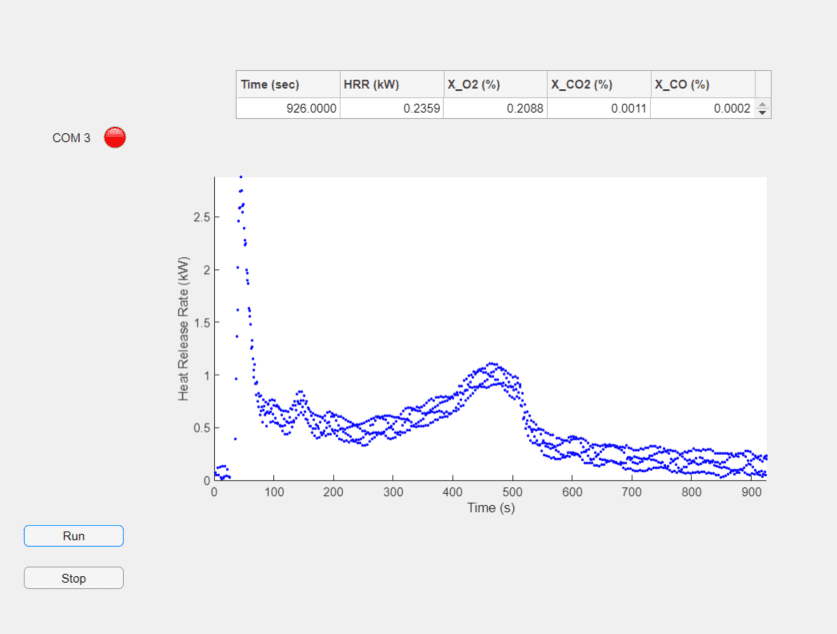

Software

- Crestline (sensor manufacturer) software to communicate with the sensor and initiate data collection, provided by company

- Matlab App for processing sensor data and displaying the HRR value as a function of time. Also saves the collected data to an Excel file for further analysis

-

- The team created this app by modifying base codes provided by Matlab App Designer

-

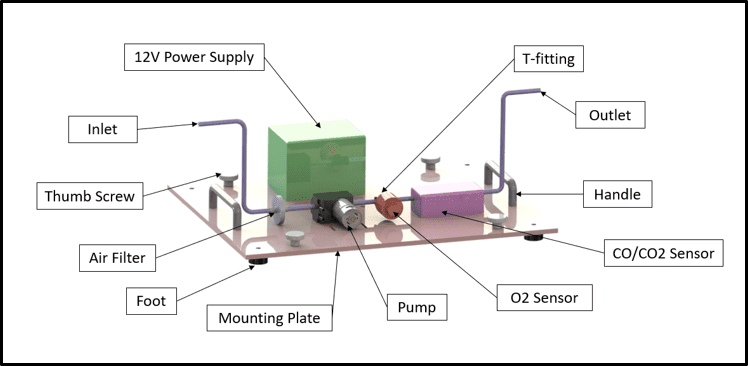

Manufacturing Process and Components

Manufacturing for this project was minimal. It involved laser cutting and drilling holes into an 18″x14″x1/4″ acrylic sheet that acts as the baseplate for fixturing components to. The holes in the acrylic are for securing its rubber feet, securing handles, and attaching the base plate to the briefcase that houses the components.

Components:

- Acrylic Sheet – for fixturing base plate, rigid but light

- Pump – 12V, low flow vacuum pump for air

- Bioenno Battery – 12V, rechargeable

- Crestline CO/CO2 Sensor – detects both gas concentrations, small scale, and comes with breakout board

- Ao2 Citicel O2 Sensor – connects to Crestline sensor, small

- HEPA Vent filter – connect in-line, easily replaceable, keeps system clear

- Briefcase – contains all components with base plate, lightweight

- Other – tubing (1/8″ ID, 1/4″ ID), fittings, fasteners (bolts, velcro, and thumbscrews)

Testing

Testing is required to verify the device’s design. Four of the most important tests that will need to be carried out are:

- Calibration – the sensors must be calibrated using known concentration values of gases

- Compare to Known Heat Release Rate – a substance with a known heat release rate will be burned and compared to the heat release measurements our device takes.

- Flowrate – must be between 0.5 L/min and 1.5 L/min for Crestline sensor to work properly, a flowmeter will be used

- Usability – students and faculty must be able to use device with only the help of the operator manual, user experience will be tested by allowing test subjects to attempt to use the device without guidance and then surveying them on their experience

Future Work

Current events (COVID-19) have prevented the team from carrying out the necessary calibration and testing, as well as completing manufacturing. These tests will need to be completed by the sponsor once he can access the Combustion Lab.

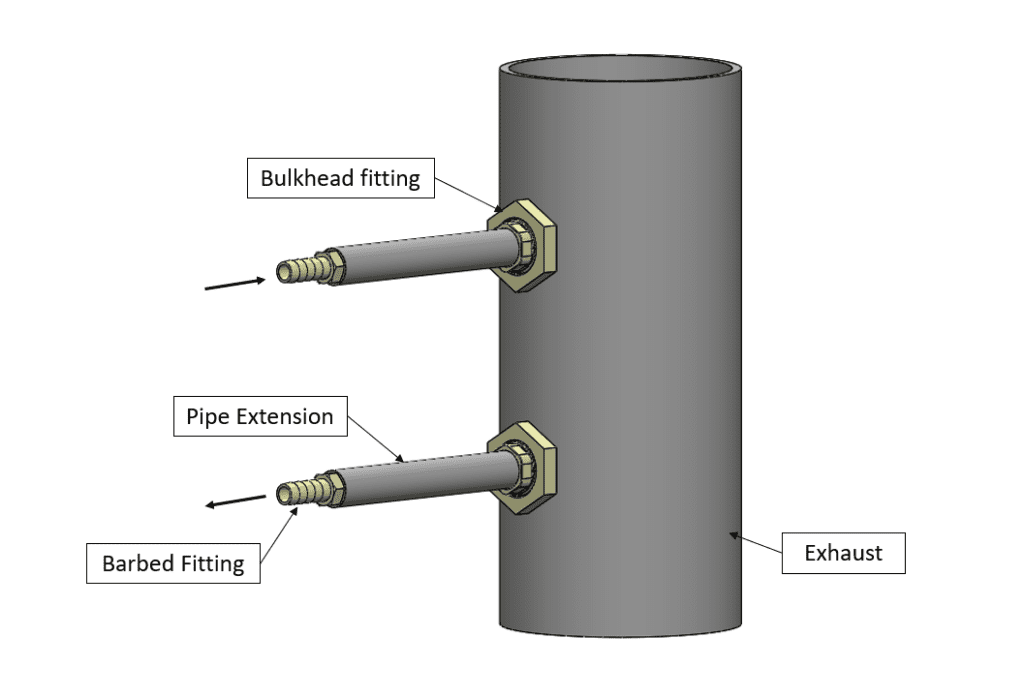

The remaining manufacturing involves adding connections to the Combustion Lab’s exhaust duct so that the calorimeter’s hoses may attach to it.

Calibration and performance testing of the device also needs to be carried out. The device should to be tested with experimental data.