Our Team

Joseph Bauer

Senior Mechanical Engineering Student Concentrating in HVAC&R

Kyle Ennis

Senior Mechanical Engineering Student Concentrating in HVAC&R

Acknowledgements

Thank you very much to Dr. Steffen Peuker for all of your guidance to this project along the way. Also, a big thank you to Air Treatment Corporation for sponsoring the project & Nick Donzelli for getting the data collection equipment installed.

Our Project Videos

Our Project's Digital Poster

Problem Statement

The purpose of this project is to calculate the energy savings by adding solar thermal collectors, provided by SolX Energy, to a VRF system. The product from SolX Energy is called ThermX, which has been installed in numerous countries throughout Europe and the Middle East. SolX claims on their website that they provide “A range of innovative technologies, collectively saving commercial businesses in excess of 60% on their energy consumption.” The goal of this report is to create a case study examining the energy savings resulting solely due to the ThermX technology. All other variables potentially affecting energy savings are to be minimized.

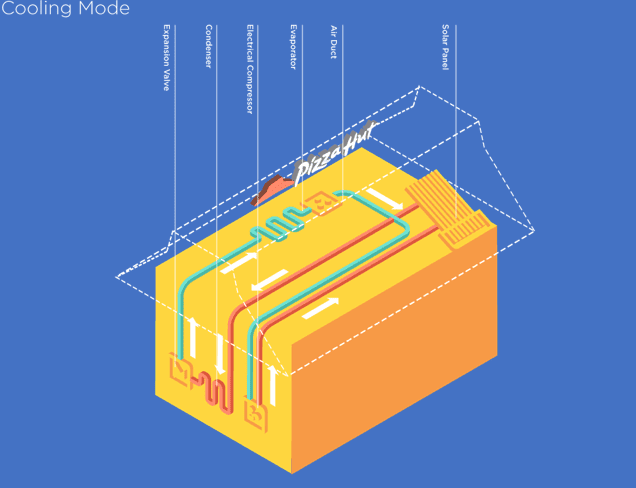

Understanding How ThermX Works

ThermX panels add heat to the section of the system between the compressor and condensing coils. This heat increases the thermal kinetic energy of the system in turn doing part of the work for the compressor. ThermX can only be added to staged compressors, VFD compressors, and VRF systems.

The image above shows a system operating in cooling mode with ThermX installed. In this case, the ThermX panel is adding heat to the refrigerant after it goes through the condenser. In the heating mode configuration, the flow is reversed compared to the cooling mode. The additional heat allows the compressor to again operate at a reduced load.

System Overview

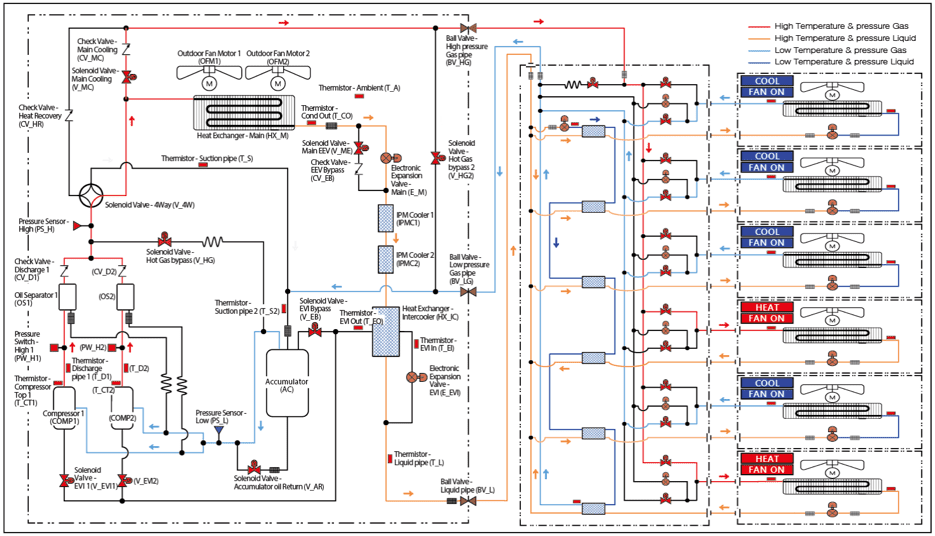

The HVAC system of focus for this project serves a BEST Express Foods office space located in Stockton, California. The project is an existing addition and alteration of two floors totaling 7,726 square feet of conditioned floor area. Air Treatment Corporation completed the installation of the ThermX panels for the project. A VRF system consisting of two 12-ton Samsung DVM S Series, Heat Recovery Units will serve the space. Within each 12-ton unit are two compressors connected in parallel. After the refrigerant exits the compressors, it will be routed through two ThermX panels. Samsung DVM S Series, Wind-Free™ Mini 4-Way Cassettes disperse/absorb energy to/from the conditioned space depending on whether heating/cooling is needed for each room. Seven Samsung DVM S Series, Mode Control Units (MCU), one serving all of the cassettes in each zone, will allow for simultaneous heating and cooling of different rooms in the office space. The major pieces of the system equipment are shown below along with a diagram detailing refrigerant flow within a standard system.

Data Analysis

Analyzing Collected Data

Air Treatment Corporation (ATC), the manufacturer’s representative and installer of the ThermX panels for the project, was the company we worked in coordination with for this project. Nick Donzelli, an Industrial Refrigeration Sales Engineer with ATC, was our main point of contact for any sort of question regarding the ThermX project in Stockton and was the one who got the data collection system set up for remote access. Due to the COVID-19 pandemic, the installation of the ThermX system was delayed and therefore we were unable to complete any energy savings analysis. Of the data that will be collected, the current draw of all four individual compressors will be crucial for energy analysis. The compressors make up almost all the power consumption for the whole system, so therefore the percent savings can be calculated using the equation P=IV, which was recommended by Christopher Bryan, a Samsung HVAC sales representative. Breaking down the equation P=IV, P stands for power in units of Kilowatts (kW), I stands for current measured in amps (A), and lastly, V stands for voltage measured in volts (V). The power of each of the four compressors will have to calculated individually and then added together to get a total system power consumption in kilowatts. The voltage of each compressor can be found from the data sheet linked above for the Samsung DVM S Series heat recovery condensing units to be 208-230 V. As advised by Christopher Bryan from Samsung, 208 Volts is used for the power consumption calculation.

Predicting Yearly Savings from ThermX

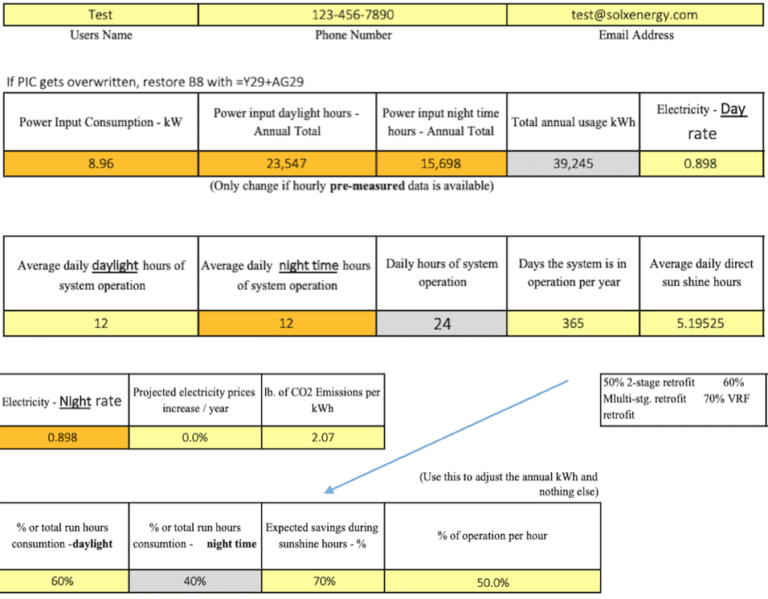

SolX, the company that created ThermX, has a calculator to predict savings that can be compared to the actual results. The ThermX power savings calculator developed by SolX uses the average daily hours of sunlight, system type, and running hours to calculate the percent savings per year. To find the predicted savings on a given day, you can enter the amount of sunlight hours for the day and the percent savings will be listed on the following tab. The total energy savings would need to be divided by 365 to obtain the predicted amount for that specific day. More information on how to calculate these values is in the final report. The calculator can be seen below this section of the website.

Comparison to Photovoltaic System

It is important to determine if the ThermX system is more attractive economically than a typical photovoltaic solar panel system. According to Energy Sage, the average price per watt for photovoltaic solar panels is 2.98 $/W. It can also be found that solar panels produce 16 watts per square foot. The results calculated from these values can be compared to the predicted savings from the ThermX calculator. For more a more accurate comparison, it is recommended to reach out to a solar power company that works with industrial facilities to calculate the savings and required square footage of solar panels to produce a particular amount of energy at the site in Stockton.

Recommendations

The next group to work on this project should:

- Predict yearly savings of ThermX panels using the power savings calculator developed by SolX

- Collect data with and without the ThermX panels connected to the system

- Perform energy consumption analysis of two different operating states (with and without ThermX connected)

- Determine the percent energy savings due to ThermX and compare with the estimated value

- Compare energy savings from ThermX with photovoltaic solar panels