Acknowledgements

We would like to thank our project advisor, Professor Lee McFarland, and our project sponsor, Mr. Michael Brennan for their continued guidance. We would also like to thank all the professors that taught us throughout our time at Cal Poly.

Our Team

Aaron McCallister

I’m an ME student from Albuquerque, NM. First and foremost, I want to make the world a better place. For me, the starting point is improving education. This project allowed me to think like a designer, entrepreneur, and educator to create a real-world product. Outside of school, I’m a soccer player, mountain biker, and adventurer!

Emily Richter

I’m a mechanical engineering student from Santa Rosa, CA. This project excited me because it allowed me to apply my mechanical design skills to a product that encourages collaborative learning. Outside of school, I enjoy running, camping, and being outdoors!

Jett Bolusan

I am a fourth year mechanical engineering major with an emphasis on renewable energies. I am from Kihei, Hawaii. This project interested me because school and learning is often looked at as a chore when it really shouldn’t be. Designing something to make learning that much easier may help change people’s outlooks. Outside of school I enjoy hiking, cliff diving, fishing, snorkeling, and stargazing.

Our Project's Digital Poster

Problem Statement

Workspaces are often pressed for space and can only hold a limited amount of furniture. Workspaces are also often set up for certain styles of interaction, being individual work or collaborative. One specific area is the classroom. Professors often have a preference for one of the two and using regular tables found in a classroom can be time consuming to swap between the two learning styles, or not possible depending on the classroom configuration. Coact Furniture saw this need and determined that there should be a table that is able to accomodate both the lecture and collaborative learning style.

Objectives

Initial Desired Mechanisms

Initially we thought to create a table capable of nesting, adjusting height, and adjusting surface area but realized that the main focus should be on size adjustability.

Concept Design

Decided on a table that would:

- Have a modesty panel

- Extend in two directions by sliding and opening the modesty panel

This project is sponsored by CO-ACT FURNITURE.

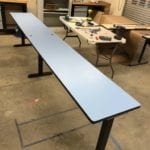

Final Design

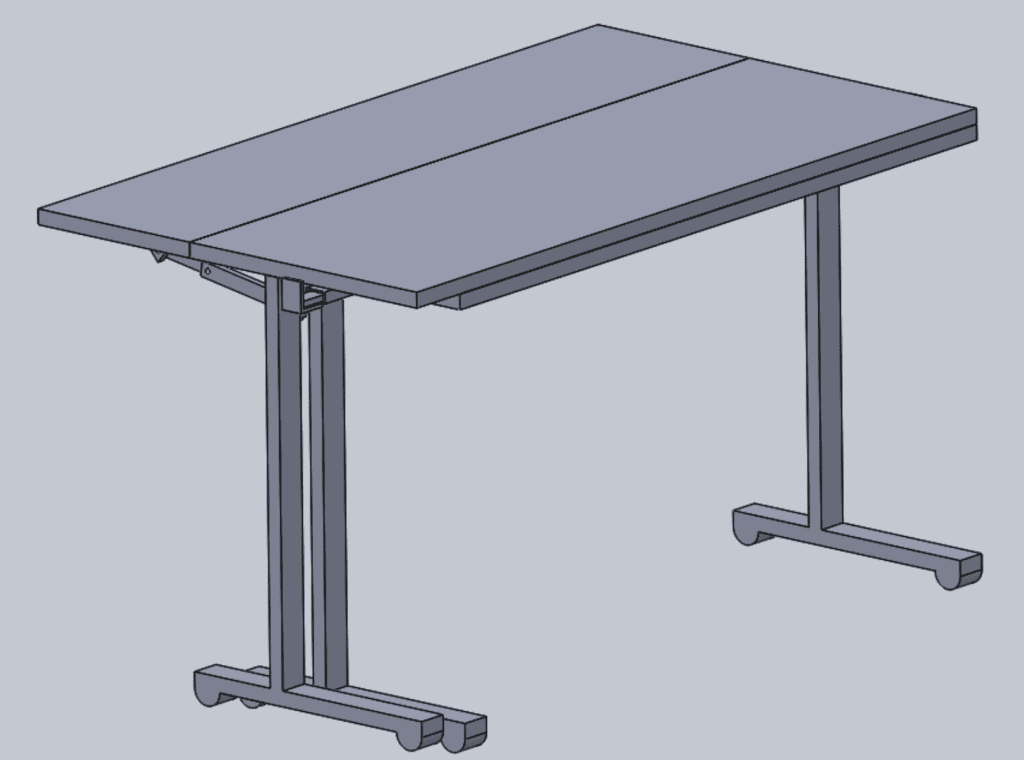

Final Design in lecture configuration

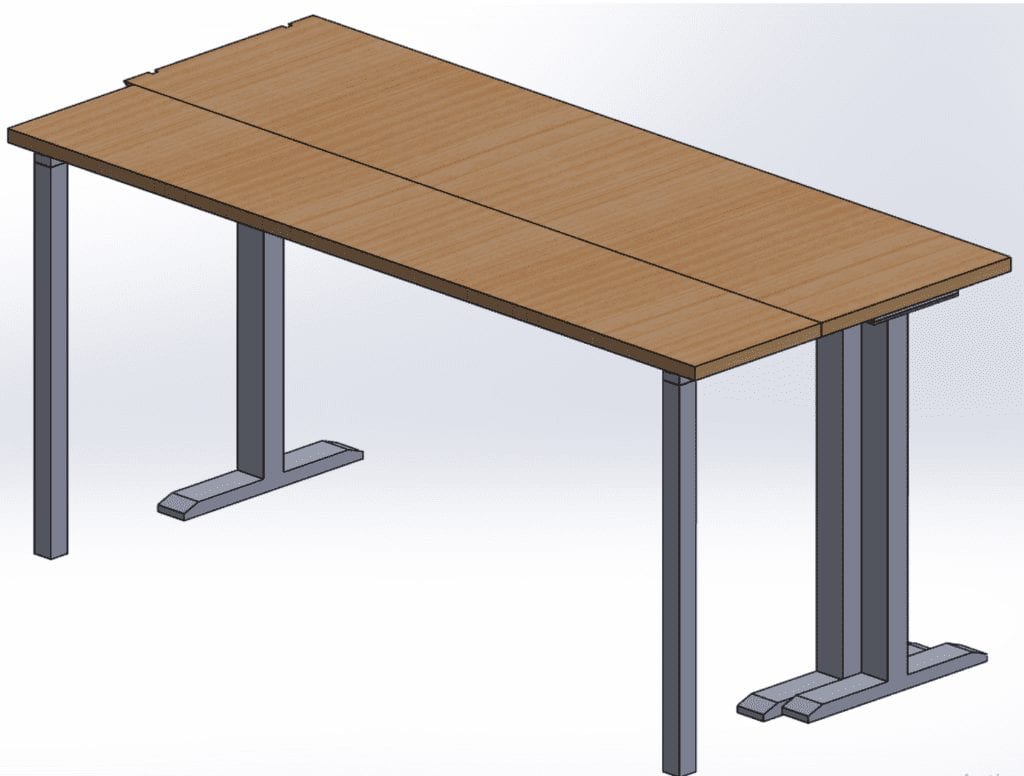

Final Design in collaboration configuration

Difficulties/Next Steps

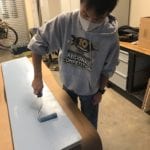

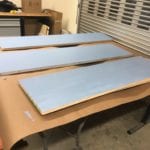

Initially we designed for mass production, gathering materials that were premade. We wanted a design that allowed our sponsor to just procure the table parts and allow for easy manufacturing and sale. With this in mind, our tabletops were designed for external tabletop manufacturers. What we failed to understand was the pricing of these manufacturers and thus had to create our own tabletop surfaces.

Next steps would include possible material adjustment as well as simplification in some of the geometries (the ridges) in our tabletops. Tolerances should also be adjusted now that we have created an actual product and know exactly where the difficulties lie if one were to make the tabletops using limited manufacturing tools.

Special Features

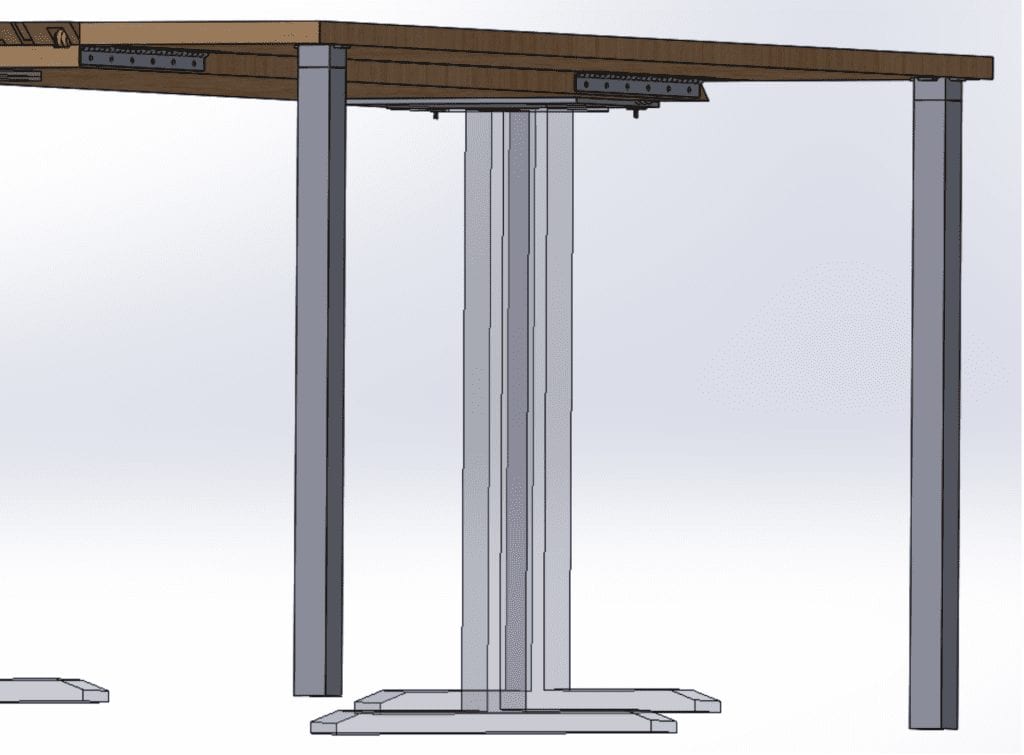

- Folding modesty panel legs for added table strength and nesting ability

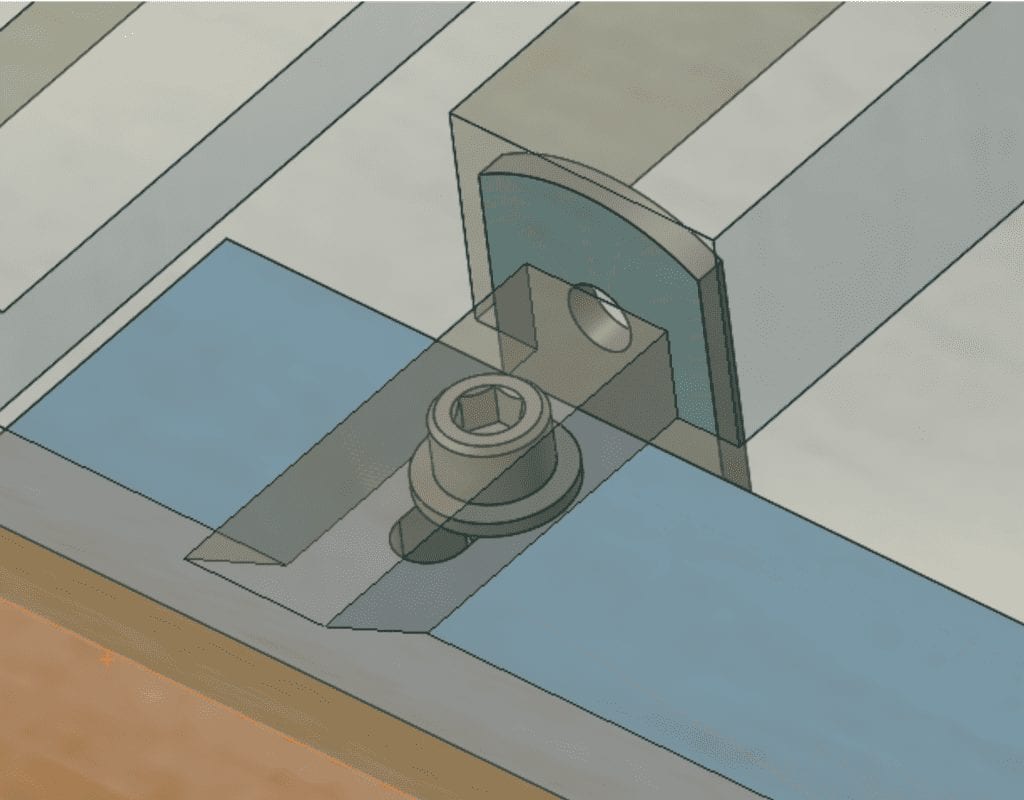

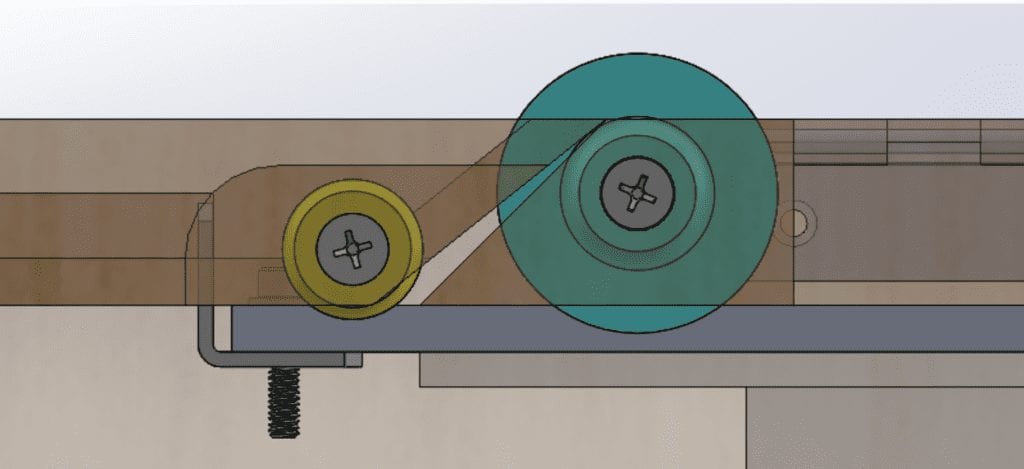

- Angle brackets at sliding table interface for extra support

- Angled edges at sliding table interface to allow for easier reconfiguration

Test Results

- ~30 Seconds to reconfigure table

- Relatively small center deflection of 0.25 inches from 150lb force

- Total table weight of ~40 LB

- 3 pinch points located at the

- Modesty panel and main tabletop interface

- Modesty panel legs

- Sliding surface interface

*Notice: Hands are not near pinch points during operation and thus should not be a large safety concern