Our Team

Our team is comprised of four motivated industrial engineering students. Each of us have an interest in automated asset management that drew us to this project. We thoroughly enjoyed our time collaborating with Chevron.

Jack Lugo

Project Manager

Jack Lugo is a student at Cal Poly from Loomis, California studying for an undergraduate degree in industrial engineering as well as a graduate degree in engineering management. Over the course of this project, he has led communications with the project sponsor as well as with advisors.

Vikrant Mannemela

UI/UX Designer & Technical Writer

Vikrant Mannemela is an Industrial Engineering major from Fremont, California. During the duration of the project his roles included working on developing the asset management system wireframe and the user guide to explain the system functionalities.

Corey Rumbaugh

UAS Specialist

Corey Rumbaugh is an Industrial Engineer from Pleasant Hill, CA. His main roles involved overseeing UAS-AI development, creating wireframes for dashboard design, and coordinating with PolyGAIT to ensure accurate specifications. Corey also worked on the deployment of UAS to understand process feasibility.

Monique Cendejas

Project Secretary

Monique Cendejas is an Industrial Engineering major from Whittier, CA. Her key roles included taking notes during meetings to ensure comments were recorded and well understood. She was also instrumental in coordinating meetings with sponsors along with making sure that work was done in a timely manner.

Acknowledgements

We would like to thank our project advisor, Tali Freed, for assisting us and leaving the group with valuable feedback following each milestone. We would also like to thank our Chevron company sponsors Jonathan “Jon” Polly and Paul Littlefield for providing insight, direction, and necessary data from Chevron throughout the project. Additional valuable contributions came from collaboration with the PolyGAIT club, computer science students from CS480, and computer engineering students from CPE460. We really appreciate all of the help and guidance from these parties, as they truly led the group toward success.

Our Project's Videos

Our Project's Digital Poster

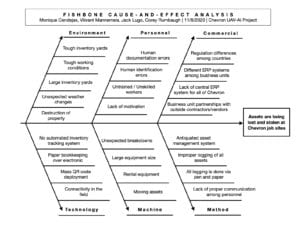

Problem Statement

Chevron has an extensive amount of indoor and outdoor assets, but there lacks a standardized system to effectively manage their operational and rental equipment. This problem results in significant financial losses at project sites around the world.

Current State

The purpose of this project is to augment certain deficiencies in asset management at Chevron. Some of these deficiencies are as follows:

- • There is a poor central ERP system for all business units,

- • Tracking methods of assets vary by department,

- • Rental assets are lost or neglected, and

- • There are resulting financial consequences of millions of dollars per year.

Objectives

The following goals were set in order to lay the foundation for this project:

• Understand the current state of Chevron’s business operations and how new asset tracking methods can aid in the solving of their asset mismanagement problem,

• Design an integrative database management system wireframe for Chevron that allows for upstream inventory to be easily tracked as well as easy asset entry, and

• Provide a user guide to showcase the functionality of the asset management system within the oil and gas industry and effectively integrate these asset tracking methods into Chevron’s upstream operations.

Design Process

Data Collection

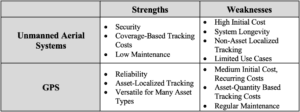

In this section, we investigated two data collection methods: global positioning systems (GPS) and unmanned aircraft systems (UAS). These options were chosen because they span different sides of a wide array of data collection methods. GPS and UAS have their individual pros and cons, depending on Chevron’s use cases.

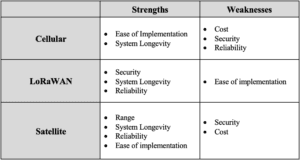

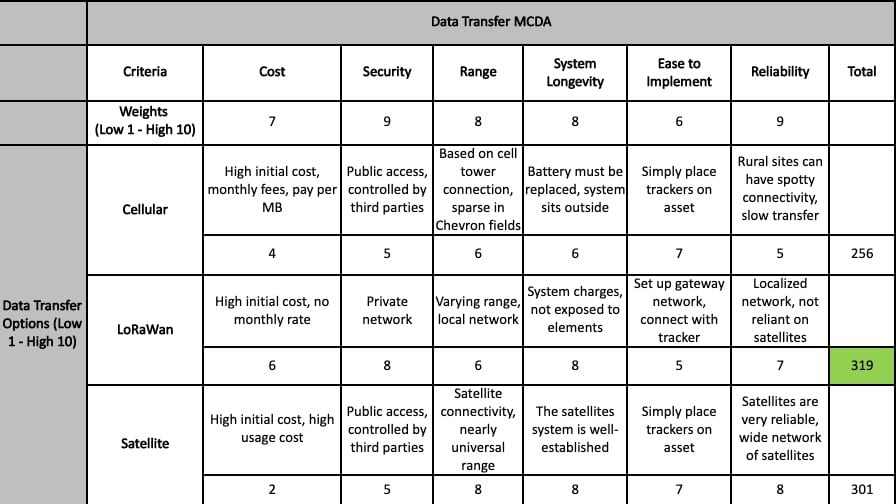

Data Transfer

It is important to determine how to transfer information about the location of the assets to a general server. This is crucial, as asset location is worthless if only the asset knows where it is. This information must be communicated to a central database. We investigated three solutions able to transfer location data from GPS or UAS to a localized Chevron network. These solutions are cellular, LoRaWAN, and Satellite.

Data Visualization

Once the location data has been collected and transferred, it must be easily visualized. The most effective method to display the non-stationary asset data is to use an integrated process dashboard. A dashboard that updates on the spot is beneficial because of how versatile it is for several Chevron use cases. An operations manager can use the dashboard to understand the financial consequences of overdue rentals while a ground operator can use the dashboard to learn where a needed piece of equipment lies.

Project Constraints

Over the course of this project, our team was confronted with multiple constraints, which include:

UAS: Machine learning deficiencies

Verification: Raw data, and direct user feedback

- Design: Newly implemented technologies

Chevron

This project is sponsored by...

Solution Alternatives

Unmanned Aerial Systems (UAS)

The second data collection method involves the use of an unmanned aerial vehicle (UAV), or more commonly known as a drone, to track inventory. In this solution, a drone would be deployed and tasked with flying over a Chevron field, collect data through a camera or other technological methods, and ultimately process and upload the flight data in a prompt manner.

Tracking Technologies

GPS: The first method of asset tracking that would be useful for Chevron is the GPS system. This technology has the capability of identifying a relatively precise location of a device. GPS comes with both advantages and disadvantages that depend on environment and case use. When running actively, the battery consumption is high and causes for consistent replacement. For Chevron’s needs, the majority of assets would not need to be actively tracked and can therefore solve the problem of high battery usage by only transmitting a signal intermittently.

Cellular: Cellular asset tracking technology utilizes the same technology used in smartphones to transfer data to other individuals or to find the device’s location on a map. The asset tracking beacon’s location is determined by comparing the asset’s distance to different cellular towers in its vicinity. The relative signal strength between each of these connections is used to determine the location of the device, while inputs from the asset itself are used to transmit certain characteristics about the asset to the beacon.

LoRaWAN: LoRaWAN is LPWAN specific for devices that use LoRa technology. LoRaWAN works by gathering information from LoRa chips located in trackers and sending that information to the LoRa gateway and then to the network. LoRaWAN is unique because it allows for two networks from which to choose:the LoRaWAN private network and the LoRaWAN public network. The private network requires a company to create their own receiving towers. This allows a company to have full control on what information is transferred on the network as the network’s sole operator.

User Interface Dashboard

The chosen data collection method will output raw location data in the form of GPS coordinates. While the specific asset location data is valuable for Chevron, the coordinates alone are not sufficient in solving the larger problem at hand, as it would be difficult to efficiently locate all assets at once, which would defeat the purpose of the system. To combat this issue, the team has recognized the need for an integrated asset management dashboard. This dashboard is instrumental in fixing the key problem that Chevron experiences throughout different business units at their company: a lack of communication, organization, and transparency. With a well-built dashboard, Chevron can log all of their equipment/rental information, locate all of their assets on an interactive map, view a financial breakdown of rentals fees and upcoming due dates, view status of site projects, and much more.

Validation & Verification

Multiple Criteria Decision Analysis (MCDA)

According to the sponsor at Chevron, the following important constraints should be considered to determine the optimal asset tracking technologies.

- • Cost

- • Security

- • Range

- • System Longevity

- • Ease to Implement

- • Reliability

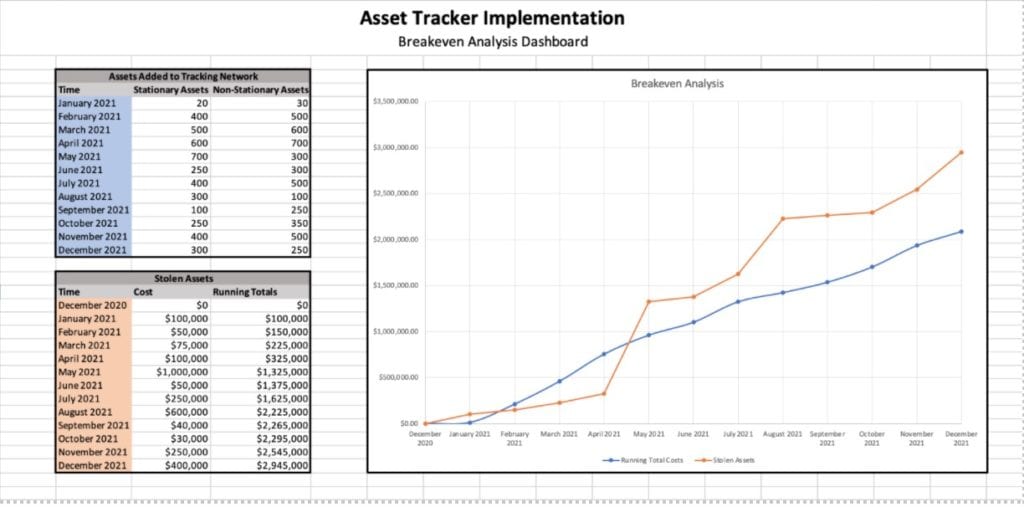

Economic Analysis

In order to determine the economic value of implementing this system, we created a strictly economic decision-making tool that can be used by Chevron personnel to determine whether or not they should install asset tracking technologies on a certain allotment of assets. The criteria that need consideration in order to make this decision are:

- • Number of assets receiving asset-tracking technologies

- • Types of assets receiving asset-tracking technologies (fixed vs. non-fixed)

- • Amount of money usually spent on late and/or replacement fees for a group of assets that size

Sponsor Feedback

In order to determine if the dashboard design is what Chevron was expecting, we presented our solution to the project sponsor Jon Polly. After presenting our wireframe to Jon, he informed us that the design and functionalities fulfilled his expectations for the company. He specifically stated that it was “everything [he] wanted in a wireframe”. Other verification methods include having been in constant communication with several Chevron sponsors to run solution ideas by them at every new step in the process, and communicating with other group members to make sure we all interpreted the specifications similarly.

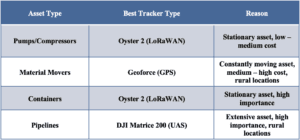

Final Recommendation

We are recommending that Chevron integrate our wireframe dashboard concepts into their 2024 ERP design. Creating a function dashboard that utilizes the different pages and ideas that we came up with will drastically help Chevron with their upstream operations. Rental assets will now be more often returned on time and there will be higher visibility regarding where non-stationary assets are located. In order to collect the location data, we are recommending Chevron to implement a LoRaWAN system across all operations to achieve better range, lower battery use, and higher security. To collect the specific asset location data, Chevron should use either UAS, Cellular, or GPS trackers, depending on the specific business use case (use cases summarized in table). Finally, Chevron should further investigate the UAS-AI feasibility in order to create a proprietary system that can automatically tack and manage assets.

Conclusion & Future Steps

While we provided an asset management system wireframe and information supplementing the best choices for asset tracking regarding certain assets, there is still ample opportunity for future work. Some action items that could be further developed to benefit this system at Chevron are listed below:

- • Further train Machine Learning models to accurately identify assets.

- • Develop comprehensive UAV-AI system capable of capturing and transmitting asset location information to a central database.

- • Conduct a specific feasibility study of the different functionalities of the proposed asset management system and dashboard to quantify the usefulness of its functionalities.

Into the future, focusing on each of these items and their development would assist in making the solution outlined in this report run even more seamlessly and effectively for Chevron. Should a team take ownership of developing this system into the future, it would be advantageous for them to direct their efforts to these items so they may further increase the quality and functionality of this system.