Our Team

Maile Juarez

Research & System Design Lead

I’m a fourth year mechanical engineering student with interests ranging across the ME spectrum & beyond. I’m interested in thermofluids, controls, and computational modeling, but I’m also fascinated by disciplines outside my major like art, law, quantum physics, biology & bioethics, and more. My dream is to travel the world, and in my spare time I like running, painting, reading, going on spontaneous mini adventures, hanging out with my little siblings, learning new hobbies, and telling people I listen to podcasts.

Josue Melgar

Industry Contact & CAD Lead

I am a fourth year mechanical engineering student. I am originally from San Diego. My desire to continue my mechanical engineering career with a concentration in HVAC&R grew from my interest in thermodynamics and fluids. I am an active individual and on my free time you can always find me playing sports or hiking. I am excited to begin my professional career soon, and I know I will soon miss every moment here at Cal Poly. Dream big and stress less.

Acknowledgements

We want to thank everyone that has helped make this project possible. Special thanks to Dr. Steffen Peuker for being our advisor for the entirety of our project, ASHRAE for being our sole sponsors, and Air Treatment Corporation for aiding with the purchase of necessary equipment to make this unit possible.

Our Project's Videos

R744 Transcritical Educational Unit's Digital Poster

Purpose

The unit is a R744 vapor-compression refrigeration system intended as an educational demonstration unit to extract water from humid air.

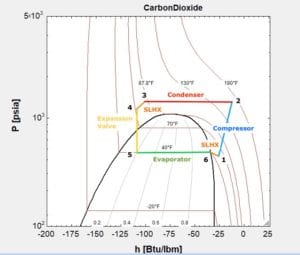

Refrigeration Cycle

Refrigeration is defined as the extraction of energy from one source and rejecting it to another source. There are 4 main components that make up a refrigeration cycle which are, compressor, evaporator, condenser, and expansion valve. These can be seen schematically on a P-h diagram below. For heat transfer to occur there must be a temperature difference in the system, a “high side” and a “low side”.

Design Choices

- We chose to use R744 (CO2) as our refrigerant since it is environmentally friendly and operates at a high absolute pressure.

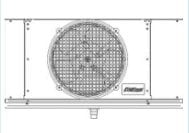

- A variable speed fan was chosen because this unit will be used for educational purposes. The variable speed fan allows the air flowrate to be adjusted from 0 to 1500 cfm. We wanted to create as much adjustability as possible so that student research programs could test for optimum settings and student labs can take multiple data points.

- For similar reasons, we got an electronic expansion valve (EEV). This allows students to adjust the pressure drop in the system and see the effect on water collection.

- We chose to use 3/8″ piping for most of our system to decrease major piping losses.

- We used a concentric tube, counterflow suction line heat exchanger (SLHX) to increase capacity, and we included a bypass in case this increases the pressure drop a significant amount.

Our evaporator unit equipped with variable speed drive

Our electronic expansion valve

This project is sponsored by ASHRAE

Background

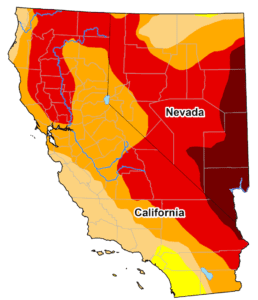

-95% of California is experiencing Moderate to Exceptional Drought, with 38% in Extreme Drought and 1% in Exceptional Drought.

-California population in drought: 30,419,000

-According to various studies, if California’s water use does not change, it will take only six dry years to become the absolute dry state in California and the United States.

-It is reported that the 2012–2014 drought in California was the most severe in at least 1,200 years. It is considered one of the worst droughts in California history.

Central Coast Weather

Places like the Central Coast of California have a unique weather. While most of the time it is sunny and mid 70s outside, the weather changes from morning to night. During early mornings and late nights, heavy fog covers cities like Morro Bay and San Luis Obispo. This is ideal weather for this unit to be used to extract water from the humid air. This led to the development of our project.

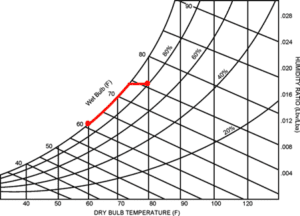

Psychometric charts (like the one pictured below) show how water can be extracted from air just by lowering air temperature. Air is cooled at a constant humidity ratio until it reaches 100% relative humidity. After this temperature, the dew point temperature, air can no longer hold the same amount of water. The water must be released as condensation as the temperature continues to release, and the theoretical amount of water collected can be represented as the mass flow rate of the air times the change in humidity ratio.

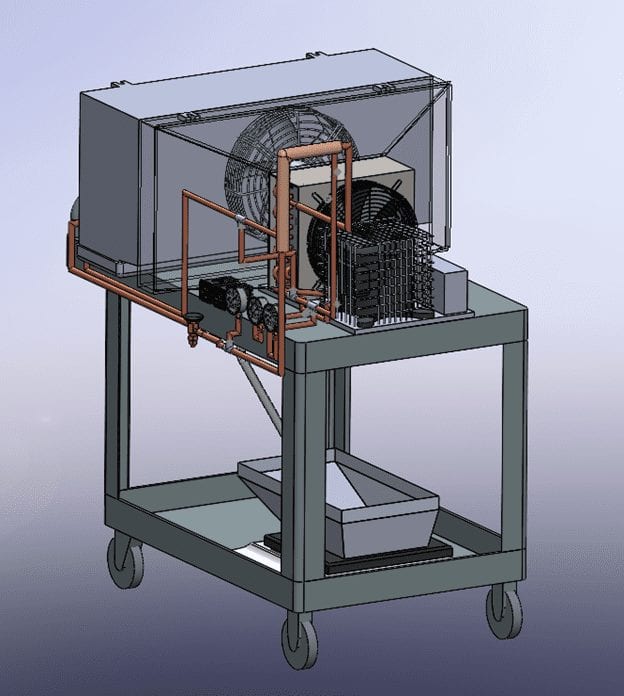

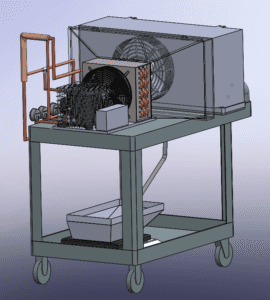

Unit Model

- Specifications

Dimensions -46.25” X 32” X 51.875” - Lightweight and Mobile

- Fit through Cal Poly HVAC lab door

- R744 refrigerant

Components

- Evaporator

- Condenser

- Compressor

- Electronic Expansion Valve

- Cart

- Pressure Gauges

- Temperature Data Loggers

- Drip Pan

- Weight Scale

- Protective Housing

- Copper Tubing

- Heat Exchanger

- Tee Fittings

Detailed Instructions

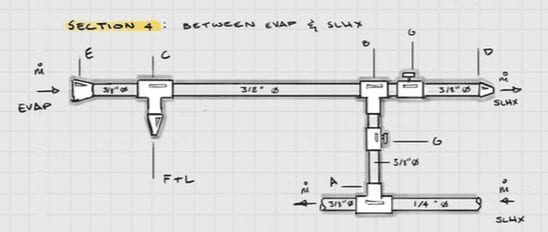

Since we weren’t able to build the project ourselves due to COVID restrictions, we bought all the parts, refrigeration components, piping, and other components necessary to build the unit. We created detailed instructions (with pictures!) for building the unit and included these in our senior design project. A future summer research project or senior project will assemble the unit according to our instructions. The image above shows an example schematic guide that future students can use while assembling our system, and the images below show a few examples of the parts we ordered using our grant from ASHRAE.

Tee fitting

Reducing union

2-way ball valve