Our Team

Khanh Phan

Senior Project Lead

I am a fourth year materials engineer at Cal Poly San Luis Obispo. I was born and raised in San Jose, California. In my time in the MATE department, I have developed an interest in both biomedical and environmentally conscious materials. In my free time, I enjoy taking in the nature around San Luis Obispo as well as participating in the many extracurricular clubs on campus.

Acknowledgements

I would like to extend a thank you to Puneet Gill at Abbott Cardiovascular for sponsoring this project, Joey Kamlet for being an awesome lab partner, and Dr. Mohsen Kivy for being my trusted advisor on this project. I also cannot forget about the MATE department and its faculty for the past four years of support and education.

Our Project's Digital Poster

Abstract

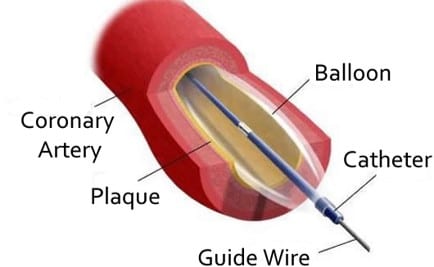

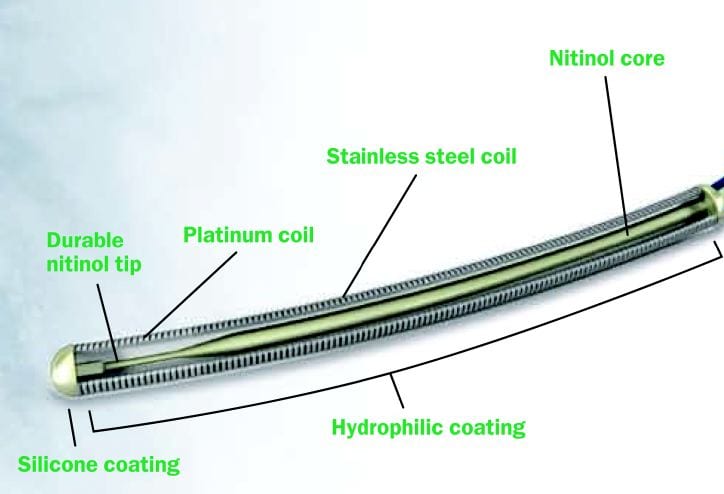

Abbott cardiovascular produces a variety of medical guide wires to accommodate a wide array of minimally invasive medical procedures. Certain types of these wires have the distal core flattened to improve specific properties such as flexibility and steerability. However, it is unknown how this affects the other mechanical properties of the wire.

Abbott Vascular provided two types of wire to test the effects of distal core flattening on the mechanical performance of the wires. One group of wires was made from 304 single spring stainless steel with no flattening performed. The other group of wires was made from 304 triple spring stainless steel, which are cold worked to a greater extent than the single spring wires. Additionally, a 10-centimeter section of the triple spring wires are flattened for testing. Mechanical performance was tested through tensile and microhardness testing. Scanning electron microscopy (SEM) was also performed to observe the fracture surface of the wire. Tensile tests resulted in increased ultimate tensile strength as well as larger elongation at failure for triple spring wire samples. Single spring wires averaged lower Vickers hardness values than triple spring wires, but also had less variance in hardness along the length of the wire compared to triple spring wires. SEM imaging indicated neither pure brittle nor pure ductile fracture occurred at the fracture surface of the wires.

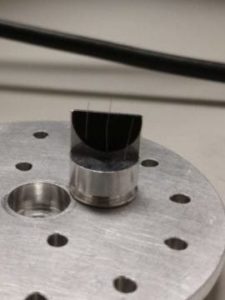

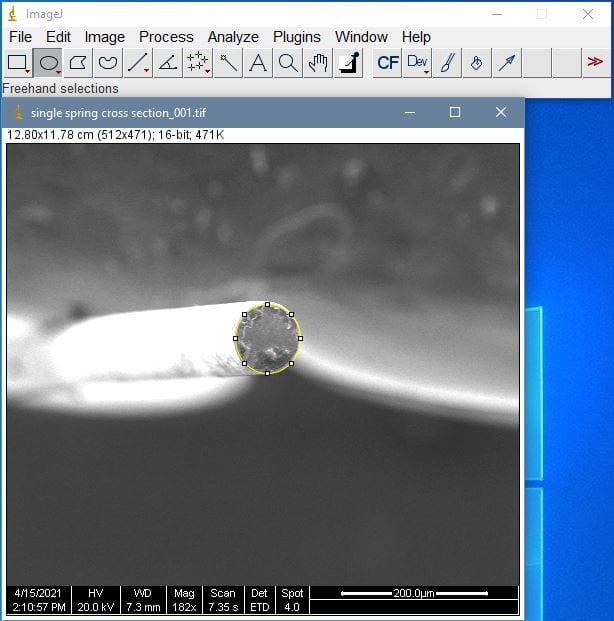

Wire Shape

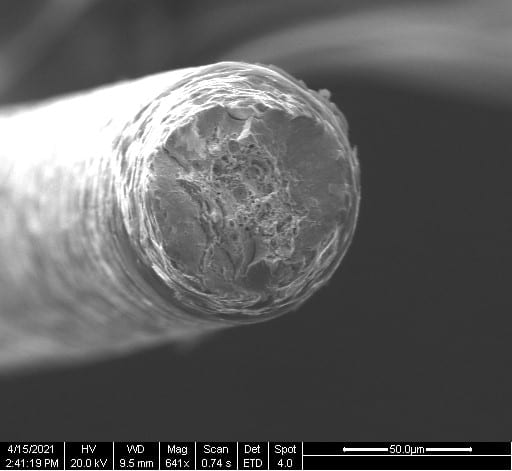

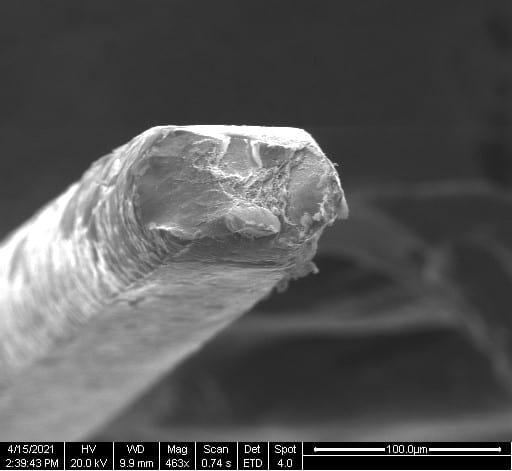

Scanning electron microscopy was performed to determine the shape of the guide wires. Random sections of guide wire were imaged after tensile testing. The cross-sectional area of the guide wires was also calculated using these images in ImageJ. SEM imaging allowed us to calculate the tensile strength of the wires as well as observe the fracture behavior of the wires. Both wires showed signs of brittle and ductile fracture with TS wires tending to exhibit more features typical of a brittle fracture compared to SS wires.

Single Spring wire sample showcasing typical ductile cup and cone fracture features.

Flattened triple spring wire sample showcasing few ductile fracture features.

This project is sponsored by Abbott Cardiovascular

Test Methods

To investigate the effects of distal core flattening on medical guide wires, tensile testing was performed using the Mini Instron. The guide wires were tested at a crosshead displacement rate of 10 mm/min until failure. The load and extension data was extracted, and analysis was performed in excel to determine the properties of each wire.

Several wire samples were imaged in the SEM with parameters of 20000 kV and a spot size of 4.

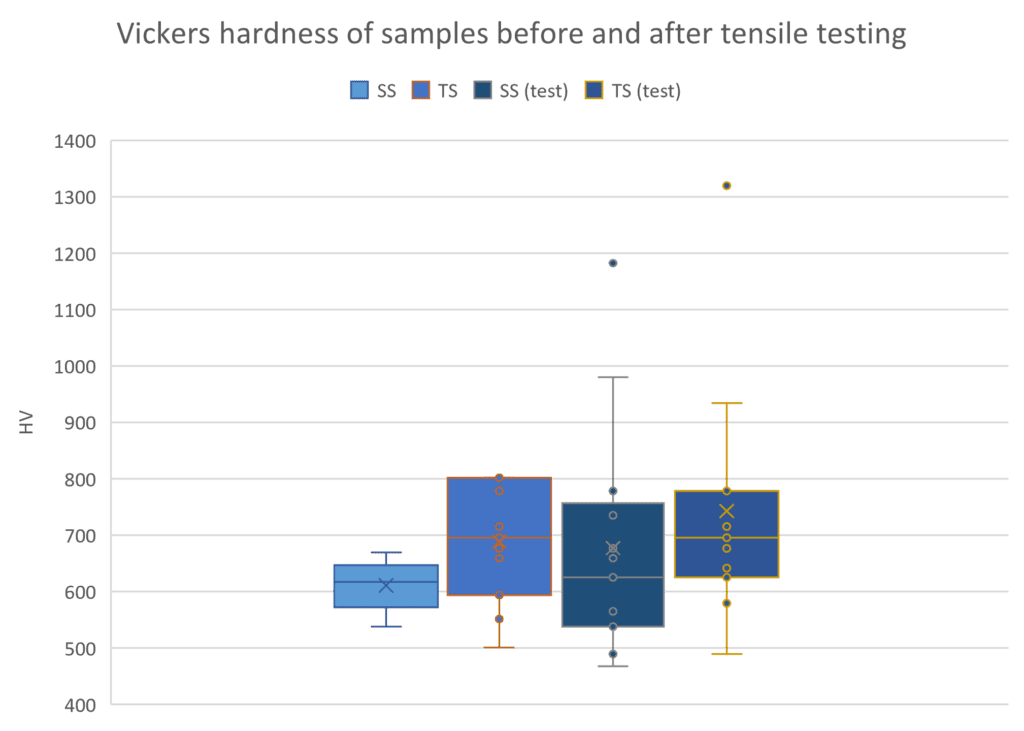

In addition to the tensile testing, microhardness testing was also performed to assess mechanical properties. 4 types of samples were tested, as-received single spring and triple spring as well as tensile tested sample of both types of wires

Samples were mounted vertically using conducting double sided carbon tape.

Note: Cross sectional area of wires was calculated using SEM images and a program known as ImageJ. (Figure below)

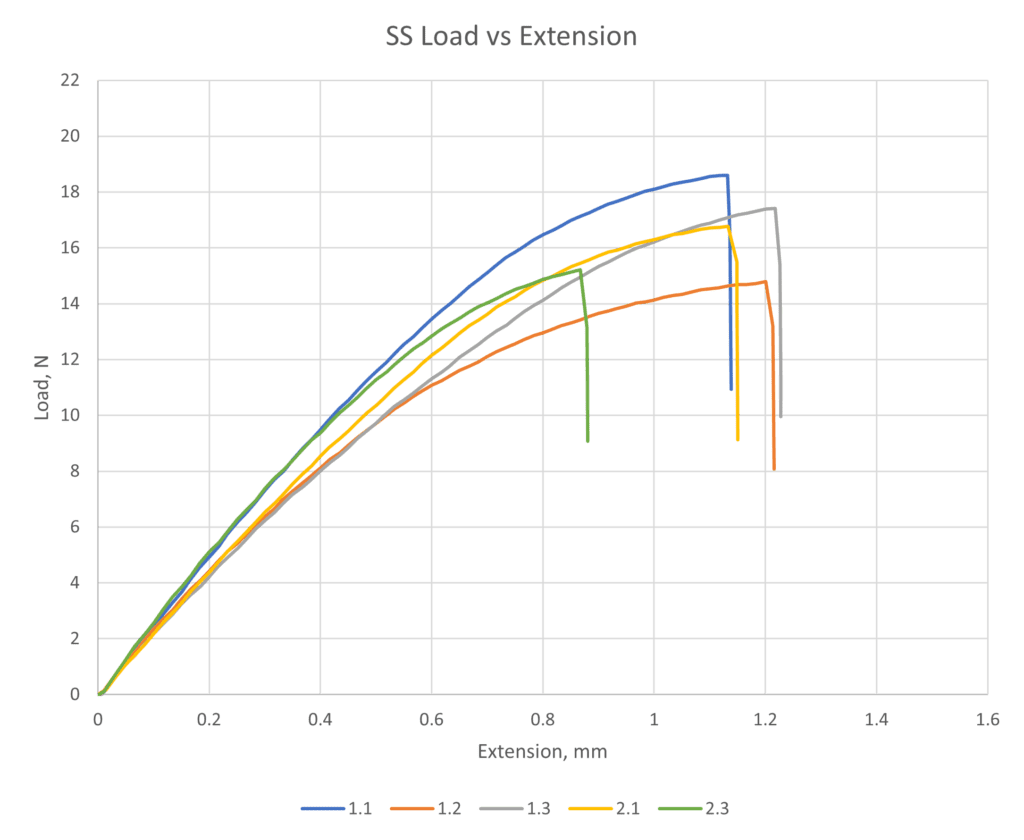

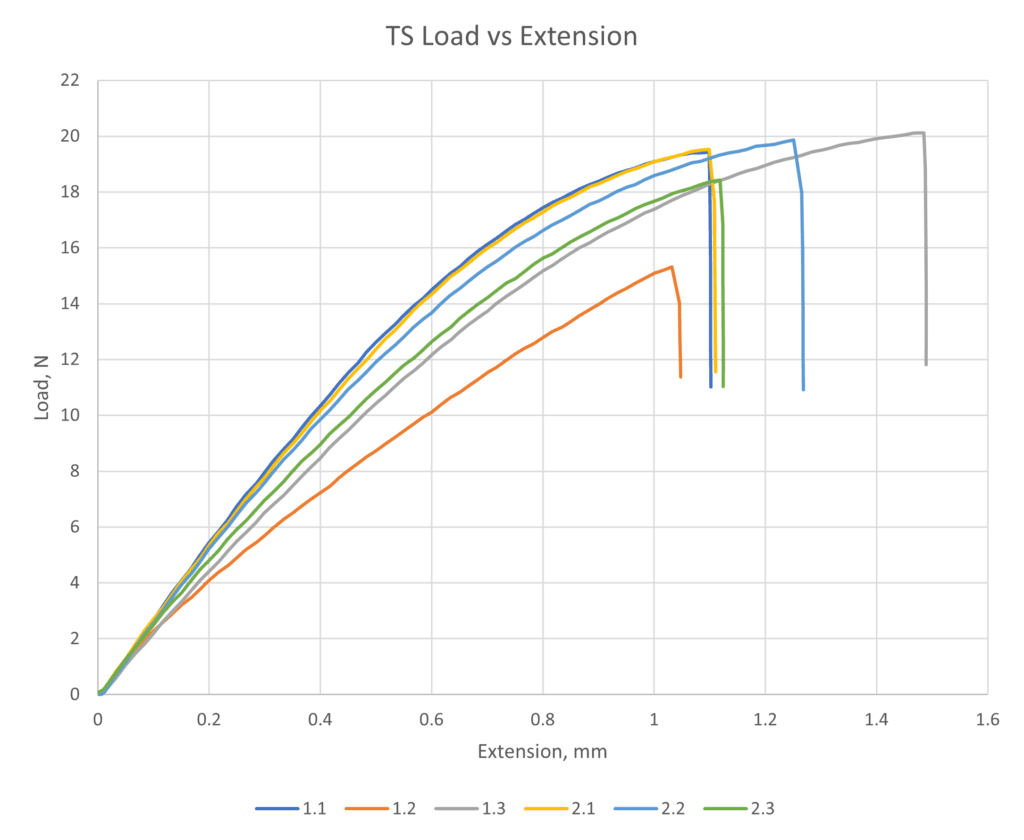

Results: Tensile Test

SS wire samples sustained an average maximum load of 16.50 newtons, which translates to an ultimate tensile strength (UTS) of 2464.14 MPa. TS wires sustained an average maximum load of 17.53 newtons and a UTS of 2458.47 MPa. Average maximum extension for SS and TS wires were 1.08 mm and 1.17 mm, respectively. 304 normally has a UTS of 505 MPa, but many studies have been conducted showing an inverse relation of strength and diameter of steel wires.5 The TS wires sustained a greater load at failure, but this is thought to be attributed to the larger diameter of TS wires compared to SS wires since both wires had the same UTS. Notably, the elongation at failure of the TS wires was greater than the SS wires and this could possibly be due to transformation induced plasticity (TRIP). This phenomena has been documented in austenitic stainless steels such as 304 and may explain this difference in elongation to failure

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

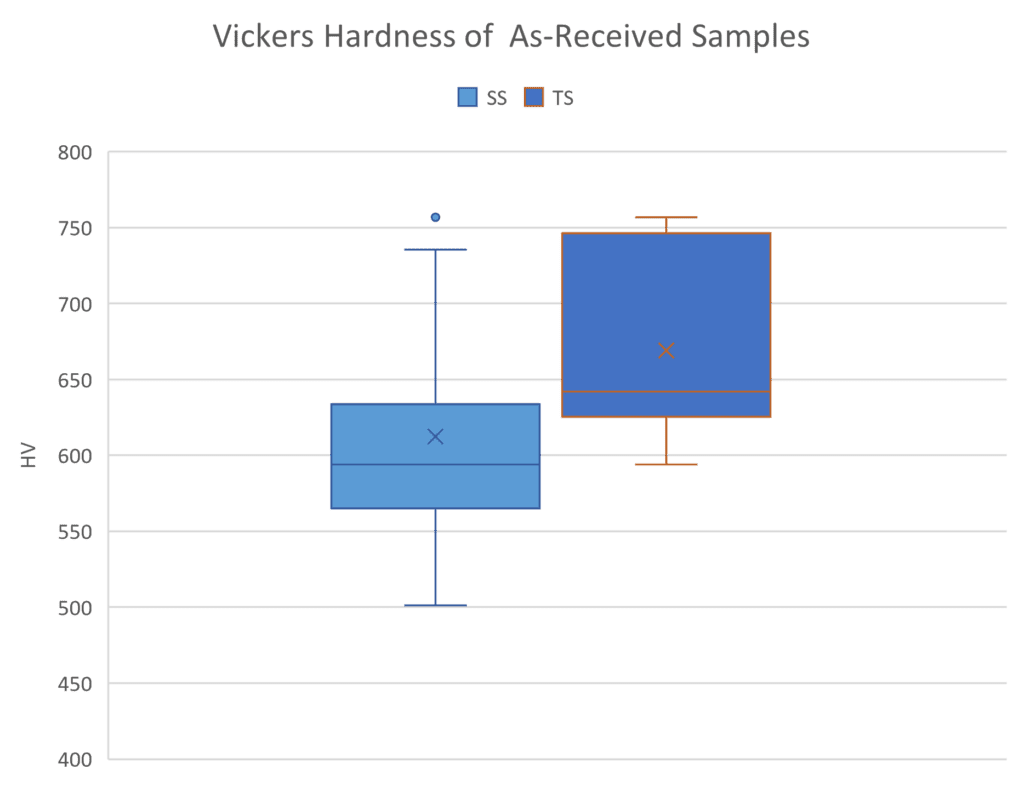

Results: Microhardness

Two methods were used to determine the Vickers hardness (HV) of the guidewires. One set of tests focused on comparing the HV of the SS wires against the TS wires. The wire sections used for these tests came from a single wire of SS and a single wire of TS. What was found was that the SS wire on average had lower Vickers hardness than the TS wire but also showed much less variance in all the measured hardness values. These results were also statistically significant through 2-sample t-test. The difference in average hardness and variance within each wire could be explained by the additional cold work that is performed on the TS wires. This relation continues with the wires tested in the as-received condition and after tensile tests. The additional cold work from tensile testing resulted in greater variance of HV values as well as higher HV compared to as-received.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Conclusions

The results of testing suggests that distal core flattening on medical guide wires made from 304 stainless steel increased the ultimate tensile strength of the wires. Flattening also increased the elongation to break of the wires, which implies greater toughness from distal core flattening. Vickers hardness also appears to increase with increasing cold work on guide wires at the cost of greater variability in values measured. Flattening increases the amount of cold work done to each wire and appears to make the wires more brittle as well.