Our Team

Megan Bolling

I am a fourth year Materials Engineering student interested in the intersection of materials and the environment. I plan on furthering my education in the areas of sustainable material development and public policy.

Madi Glozer

I am a fourth year Materials Engineering student passionate about polymers and advancements towards sustainability. My area of focus and future interests involve the integration of biopolymers as a sustainable alternative to current synthetic plastics.

Addison Wolfson

I am a fifth year Materials Engineering student at Cal Poly. I hope to take the knowledge and experience I’ve acquired and put it towards a career in research and development of new materials.

Acknowledgements

We would like to thank Dr. Sandra Pascoe Ortiz from Universidad del Valle de Atemajac Campus Guadalajara, Dr. Trevor Harding, and Eric Beaton for all of their continued support on this project.

Our Project's Digital Poster

Introduction

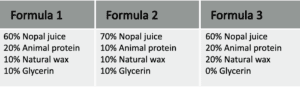

The prevalence of synthetic plastics continues to grow exponentially in the modern world. While they are cheap to make and convenient, they also produce significant amounts of waste that do not degrade. There is an increasing need for biodegradable and renewable polymers. For our senior project, we characterized a new biopolymer derived from cactus juice. Cacti, specifically prickly pear, thrive in dry environments with warmer climates and do not require much water compared to other plants. The ease with which cacti grow in the Americas makes them a readily available natural resource for polymer production. This biopolymer consists mostly of cactus juice, but also contains animal protein, natural wax, and glycerin. We were given three difference formulas above. Our goal was to determine if these different formulas degraded under UV light and how this affected their thermal and mechanical properties.

Methodology

Characterization and testing conducted:

- The QUV Weathering Tester was used to submit each of the formulas to 4 total weeks of UV exposure in 1 week intervals. Characterization techniques included FTIR, TGA, DSC, DMA, tensile testing, goniometry, and gravimetric analysis.

Standardized methods:

- UV: ASTM D5208-14

- TGA: ASTM E1131-20

- DMA: ASTM 5026-15

- DSC: ISO 11357

- FTIR: ASTM E1252-98

- Tensile Testing: ASTM D882-18

- Goniometry: ASTM 7334-08

Testing Parameters:

UV: 24/7 exposure; 1 week intervals; irradiance level of 0.89 (W/m2.nm)

TGA: 25-500C; 20C/min ramp

DSC: 25-100C; 5C/min ramp

DMA: Formulas 1 & 2-0.3% strain rate; Formula 3- 0.1% strain rate

Tensile: 50mm gauge length; Formula 1 & 2- 75mm/min strain rate; Formula 3-12.5 mm/min strain rate

Depiction of sample grouping when put in the UV Weathering Tester. The back is labelled according to which formula and subsequent characterization test will follow.

This project is sponsored by Dr. Sandra Pascoe Ortiz

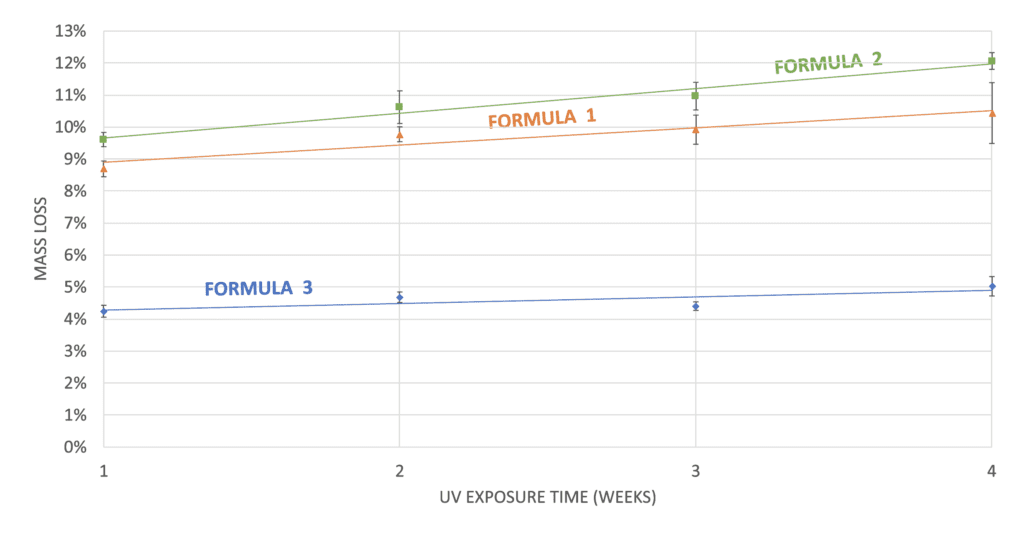

UV Gravimetric Analysis

Mass loss for each of the three formulas was recorded at each weeklong interval.

The mass loss values indicate most of the mass loss for each sample occurred during the first week of exposure. Formula 1 exhibited a mass loss of approximately 9%, Formula 2 with 10%, and Formula 3 with 4%. The mass loss observed in the first week of exposure is representative of water evaporation, further explored with TGA results. Formula 2 exhibited the highest mass loss as well as the highest rate of mass loss.

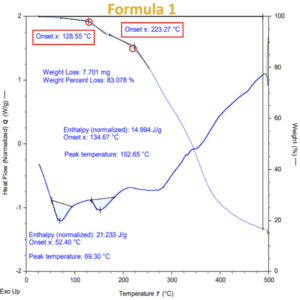

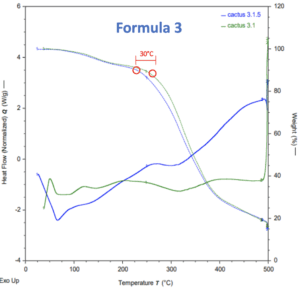

Thermal Characterization

Here in this graph, you can see the bulk of the mass loss occurrs around 128C and 223C. This mass loss at 128C is most likely water evaporation, meaning that the degradation of the biopolymer occurs around 223C. If you look at the mass loss associated with water evaporation, it has changed by about ten percent. This is important because it is the same amount of mass loss mentioned in the UV gravimetric analysis. When comparing between pre- and post-UV degradation, we saw that Formula 1 stayed mostly consistent after UV exposure, only changing by a few degrees.

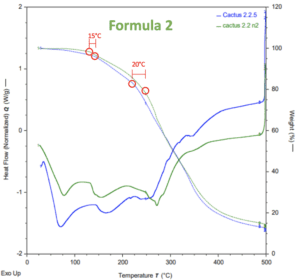

Formula 2 has a slightly different onset temperature for the first drop, and the second degradation temperature decreased by about 20C. This could be attributed to Formula 2 experiencing the most amount of mass loss in the UV weathering tester.

Formula 3’s second onset temperature decreased by about 30C. The water evaporation claim did not hold for Formula 3, however this is believed to be a result of hydrogen bonding.

Mechanical Characterization

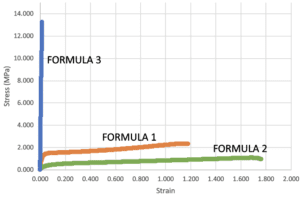

The overall results of tensile testing are shown, where the graph consists of one sample from each formula while the tabular data exhibits averages within each population.

Formula 3 exhibited significantly lower elongation as a trade-off for significantly higher Elastic modulus when compared to Formulas 1 & 2. The high modulus value is mostly attributed to the absence of glycerin that acts as a plasticizer for the biopolymer. Without the plasticizer, the polymer chains within the material are too rigid as a result of increased inter- and intra-molecular interactions and consequently doesn’t allow enough mobility. It’s exacerbated by the protein content, providing more structure as a result of strong hydrogen bonds. This also contributes to the yield and tensile strengths. Formula 2 yielded the lowest modulus and strength values compared to Formula 1 as a result of the amount of protein contained within the polymer. With the presence of glycerin and the smaller content of proterin, the glycerol molecules take up small spaces between the proteins, preventing those strong intermolecular interactions. Without as many strong intermolecular forces, there are fewer bonds to break. As such, a 10% decrease in the amount of protein changed the modulus and strength values by about a magnitude of 10. Formula 1, on the other hand, had a similar protein content to Formula 3, but also had glycerin present. With the interactions between the glycerin and proteins, the mechanical properties rested in the middle.

Conclusions and

Future Work

Minimal degradation of the biopolymer was observed, save the water weight. With only a few percent mass loss, the testing executed was not sensitive enough to detect any large changes in the mechanical or thermal properties. The three formulas behaved differently during UV exposure: Formula 3 showed less mass loss than Formulas 1 & 2, and Formula 2 showcased a large visible change in appearance. Lastly, the protein and glycerin content can be manipulated to obtain a wide range of mechanical properties, ranging from a stiff and strong biopolymer, to one that has high elongation, but low yield strength.

Based off our time constraints, our main recommendation would be to increase the UV exposure time and collect more data within the first week of degradation. Additionally, it would be advantageous to have more standardization of the processing of the material to limit variability between sheets and the amount of voids contained within it. We’d also recommend testing other routes of degradation and compare them in their rates and effects on the properties.