Our Team

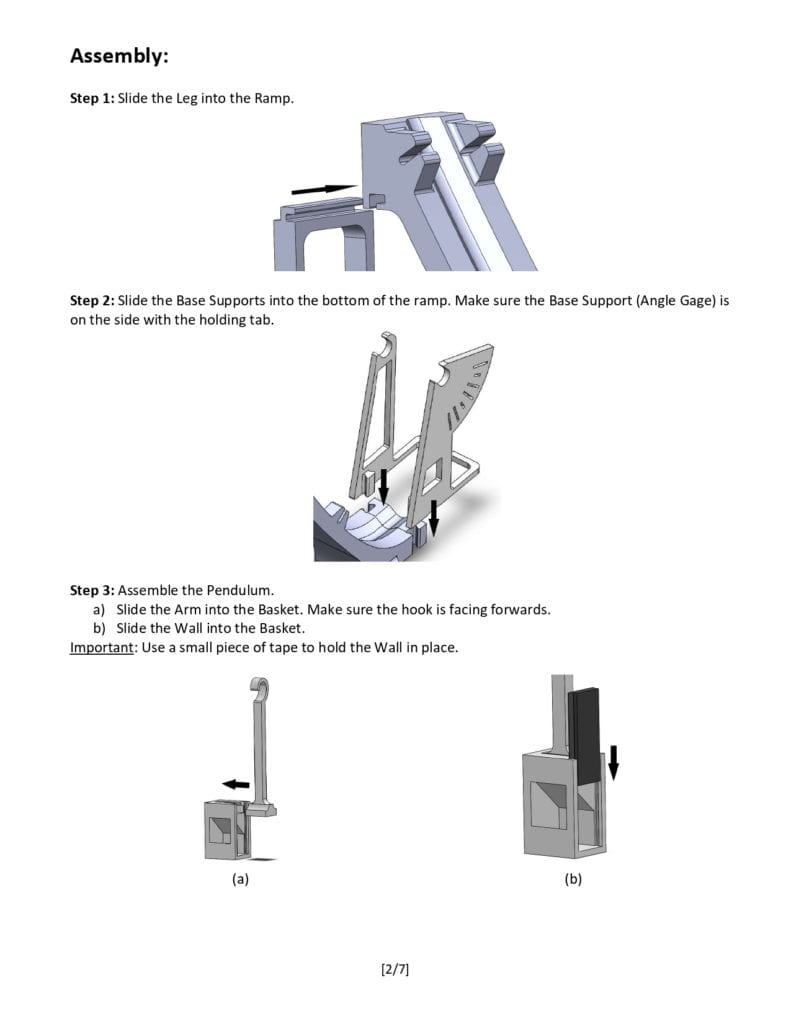

Dakota Baker

I am a 4th yr. mechanical engineering student and I enjoy learning languages, reading good stories, and history. Although I have worked and volunteered in a wide variety of different fields, it seems I have developed a knack for good documentation and lab report formatting.

Jacob Lindberg

I am a 5th year mechanical engineering student and student athlete. In my free time, I love to innovate, swim, and play the piano. My career has comprised mostly of student run ventures that provide a unique insight into the real world applications of how engineering fits within the process of a company.

Andrew Meyenberg

I am 5th year mechanical engineering student with interests in additive manufacturing, robotics, and energy. In my free time, I enjoy playing with my dog, working out, and building things. Throughout my years at Cal Poly, I have gained skills in analysis, conceptual design, testing, research and more.

Junnior Rodriguez

Mechanical Engineering student who has a passion for designing and building creative and innovative parts and products to solve problems and creating awesome things. I love anything that has wheels and embrace the challenges by using my imagination to manufacturer anything my mind could think of.

Project Videos

A quick hands-on demonstration of each activity.

RIGID BODY KINEMATICS

ROLLERS

SPOOL

ANGULAR IMPACT-MOMENTUM

CORIOLIS

Team F21 Digital Poster

Problem Statement

- Dynamics students need a way to enhance their understanding of complex dynamics principles through the aid of a hands on supplemental activity to help visually convey dynamics phenomena.

Design Constraints

(per activity)

- – Cost < $20

- – Weight < 3 lb.

- – Print time < 30 hrs.

- – Survive 4 ft. drop

- – Last > 1 school year

- – Easily transport 9-10 units

- – Showcases at least 2 scenarios

- – Can be setup < 5 min.

Overview

Due to the COVID-19 pandemic, our project was severely limited when it came to real world testing with actual engineering students. Without any student feedback, it was difficult to try to develop a learning process to use with the activities. Regardless, we were able to create a total of 6 functioning activities as well as their corresponding worksheets.

Recommendations

Throughout our time working on this project, we faced many challenges. Below are a few recommendations to help ease the process for anyone pursuing a similar project in the future:

- Develop standard fits to connect pieces

- Iterate designs as much as possible

- Create learning goals for each activity early

Worksheets

Each activity has an accompanying worksheet to guide the user. There are also questions that the student must answer all geared towards developing a correct understanding of what they did in the activity.

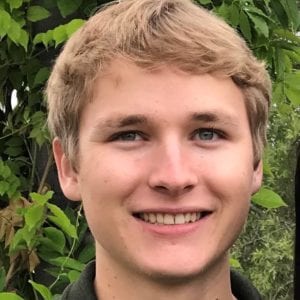

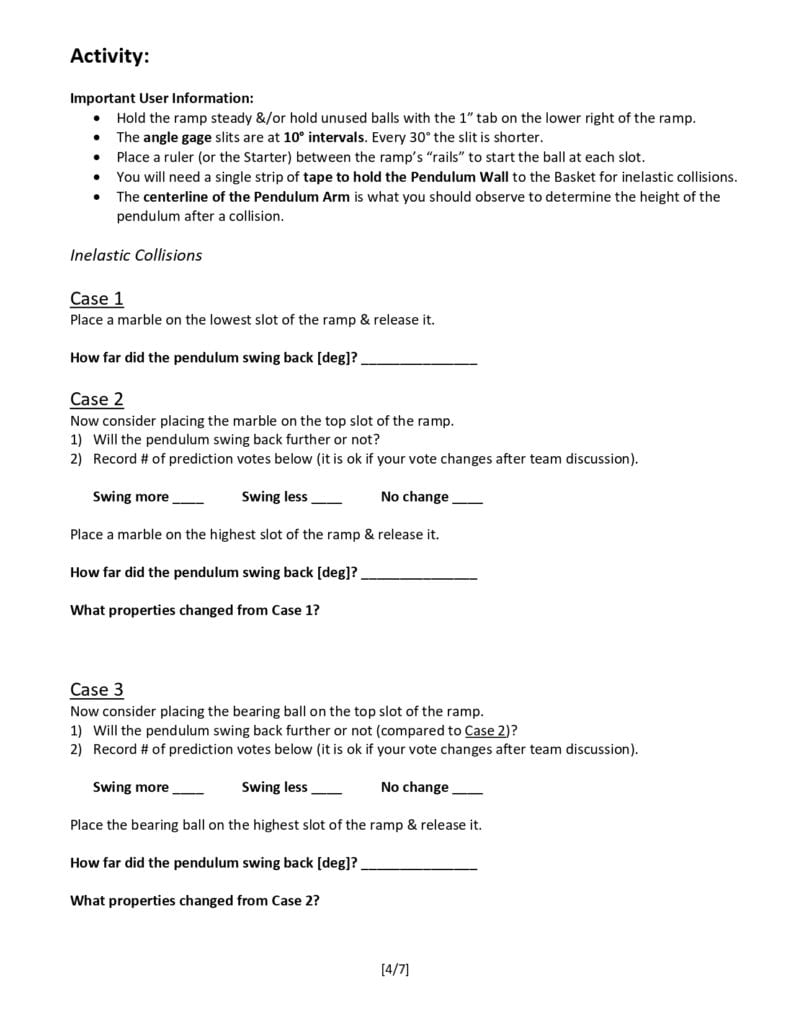

Found below is an example worksheet for one of our in class activities; Angular Impact Momentum (AIM)

AIM (1)

AIM (2)

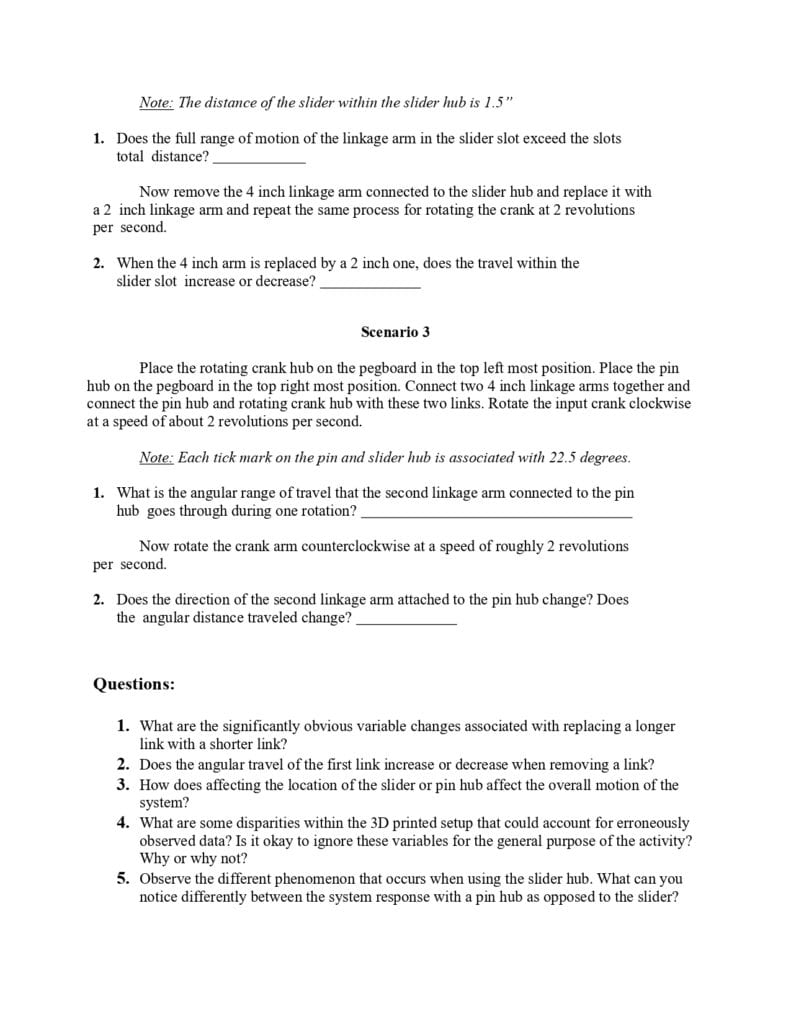

RBK

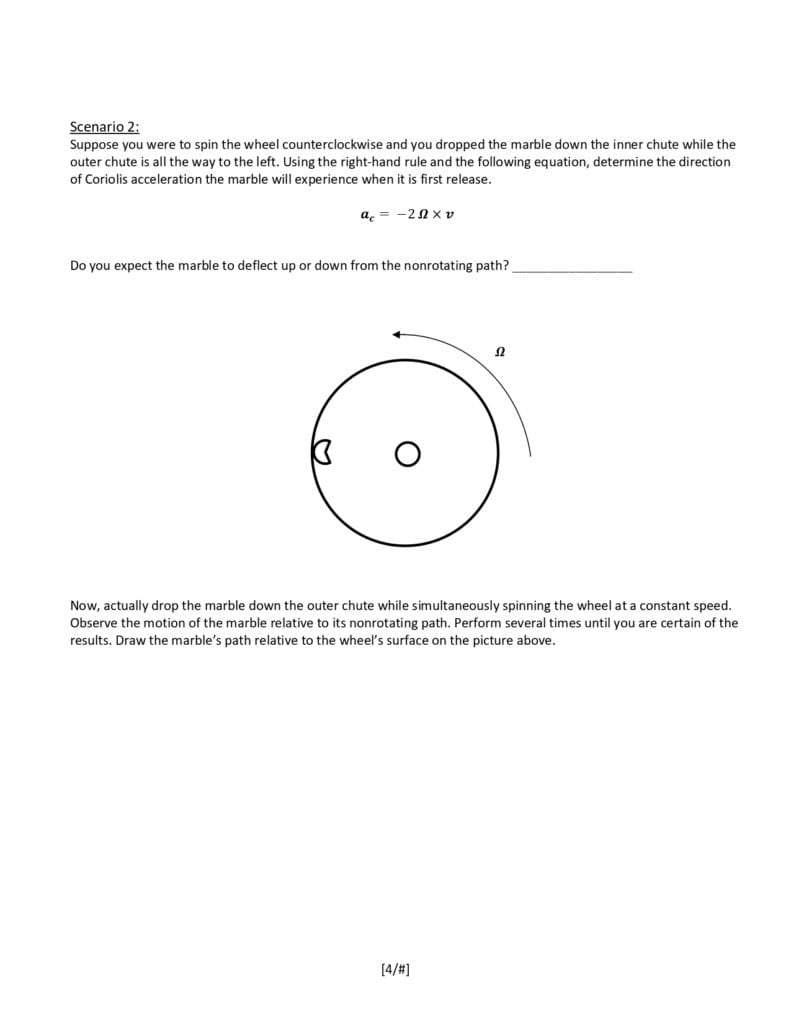

Coriolis

Sponsor: Dr. Brian Self

Advisor: Dr. Mohammad Noori

Cal Poly Mechanical Engineering

Activities

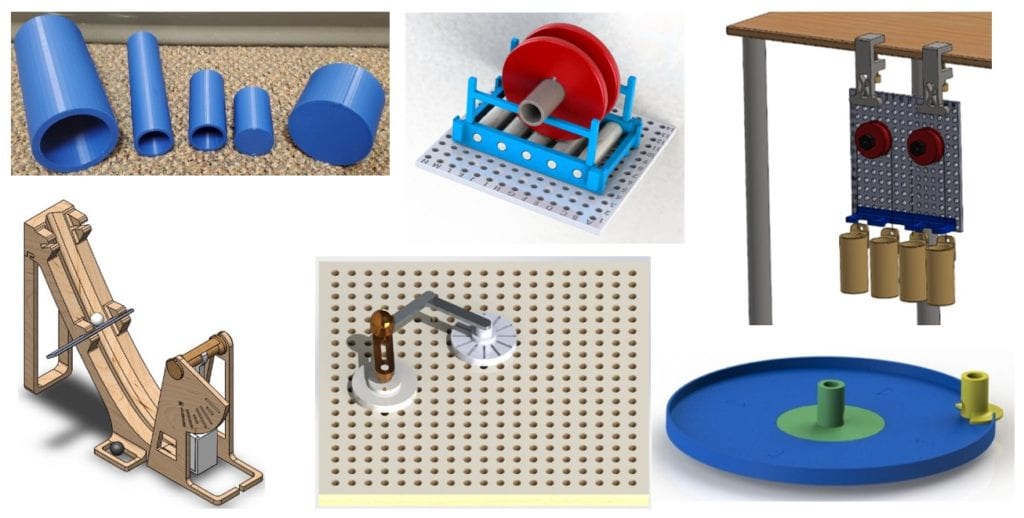

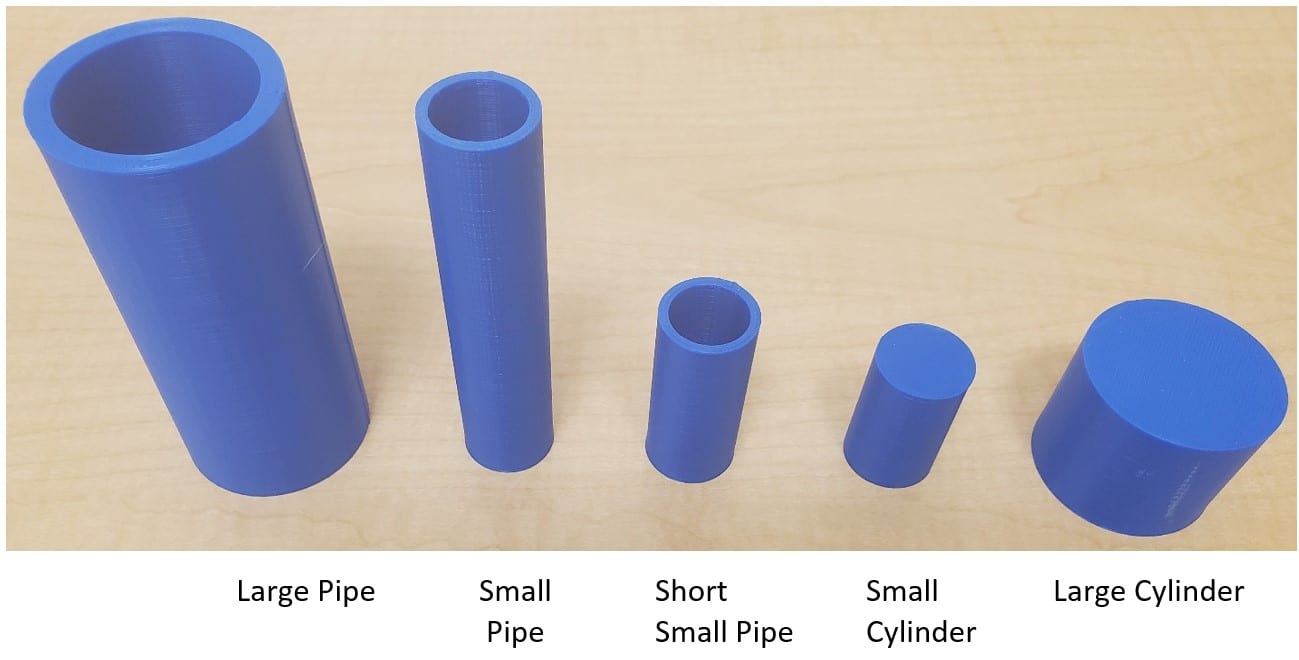

rollers

The Rollers activity develops a student’s intuition for mass moment of inertia by racing rollers of different radius, shape, and mass down an incline. The largest roller is the Large Pipe at 5 cm in diameter and 11 cm long. The “small” rollers have a diameter of 2.5 cm. The lengths of the rollers were controlled such that the Large Pipe & the Large Cylinder as well as the Small Pipe & the Small Cylinder have the same mass. The Short Small Pipe is half the mass as the Small Pipe.

Parts (5):

- – Large Pipe

- – Small Pipe

- – Short Small Pipe

- – Large Cylinder

- – Small Cylinder

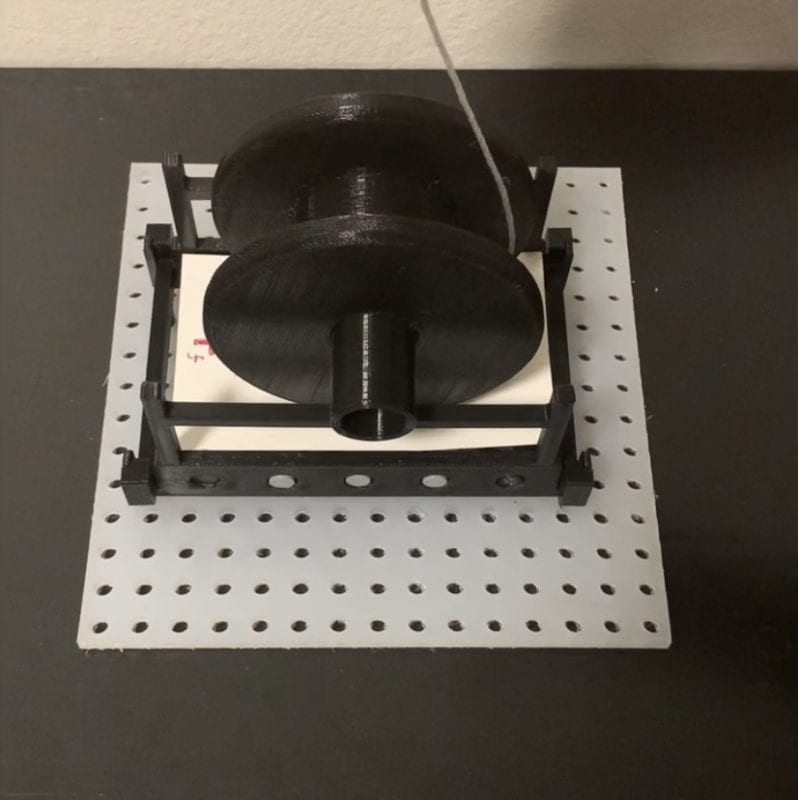

Spool

The Spool activity compares input vs friction force. Where students predict which way the spool will roll and which direction the friction force card moves relative to the spool.

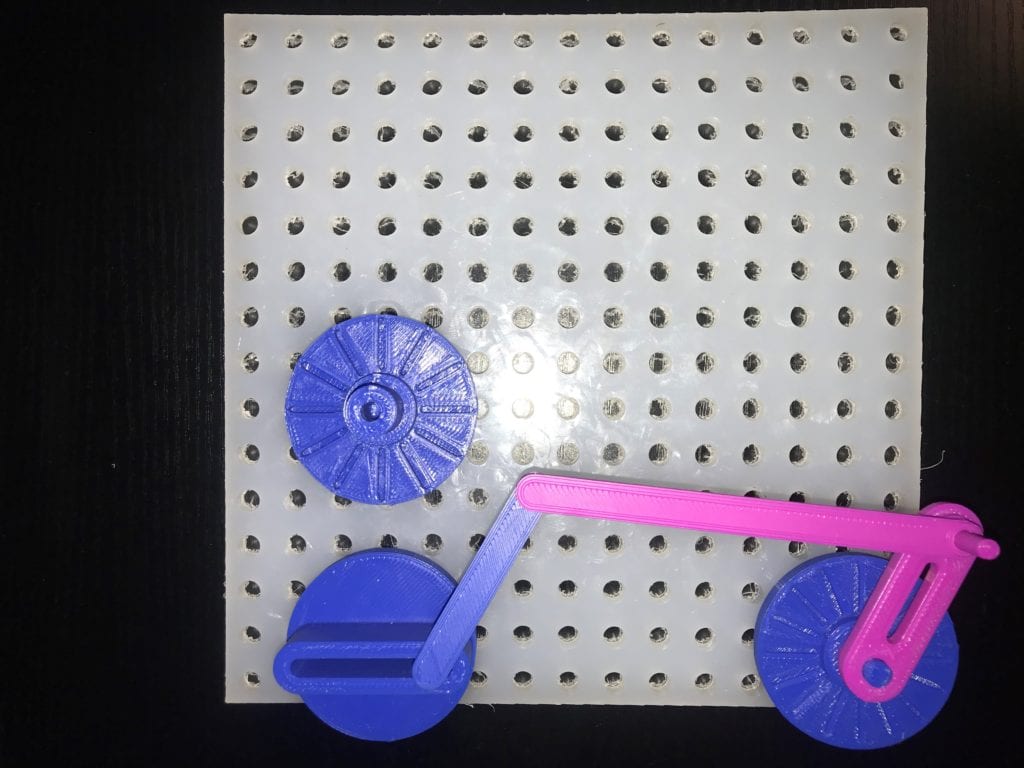

rigid body kinematics

The Rigid Body Kinematics activity was designed to be as modular as possible with the lowest amount of parts involved. The activity can demonstrate either a 2-bar, 3-bar, or 4-bar Grashoff linkage system by adding or subtracting links connecting the rotating crank hub (bottom right) to the slider or pin hub (bottom left). The modularity extends to being able to test different placements of the hubs around the 7″x7″ acrylic pegboard provided by the teacher.

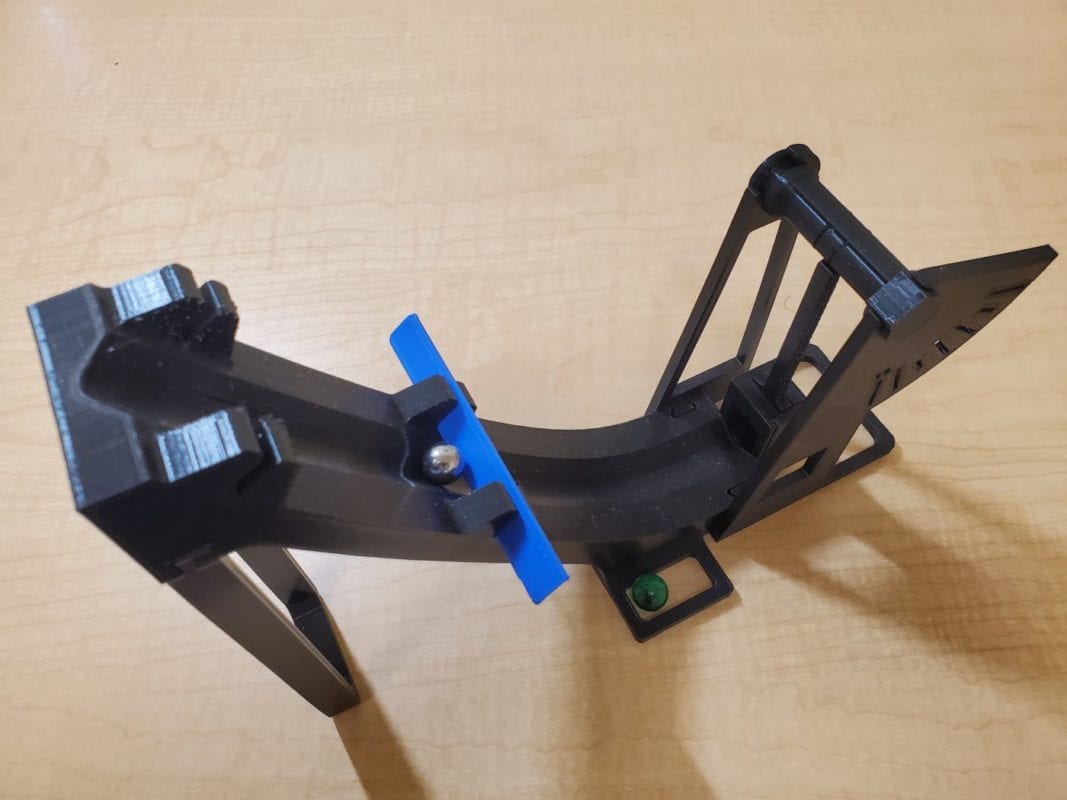

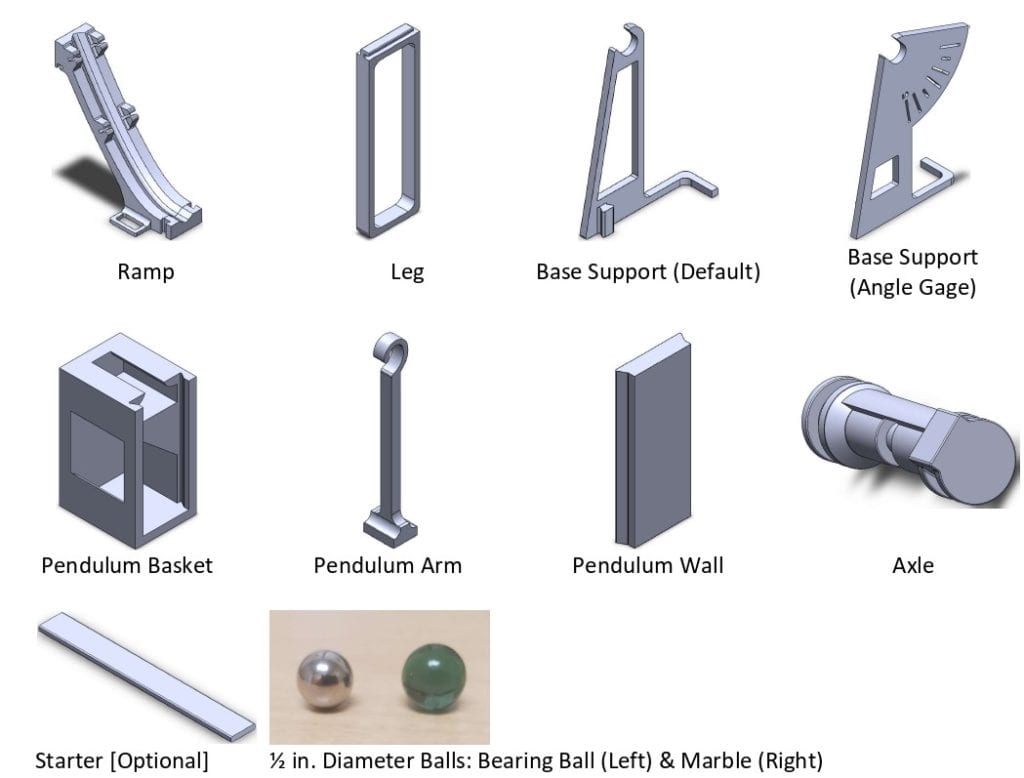

angular impact-momentum

The AIM activity develops a student’s intuition for impacts and momentum. A ball rolls down the ramp and hits the pendulum. The user then uses the angle gage to see how far the pendulum swings back. The ball’s mass is changed by using a marble and a bearing ball. The ball’s impact velocity is changed by starting it at two different heights. The type of collision (inelastic vs. elastic) is changed by turning the pendulum around. One side “catches” the ball while the other side is flat and the ball bounces off it. The activity is 10″ long, 7.4″ tall, and 2″ wide.

Parts (11):

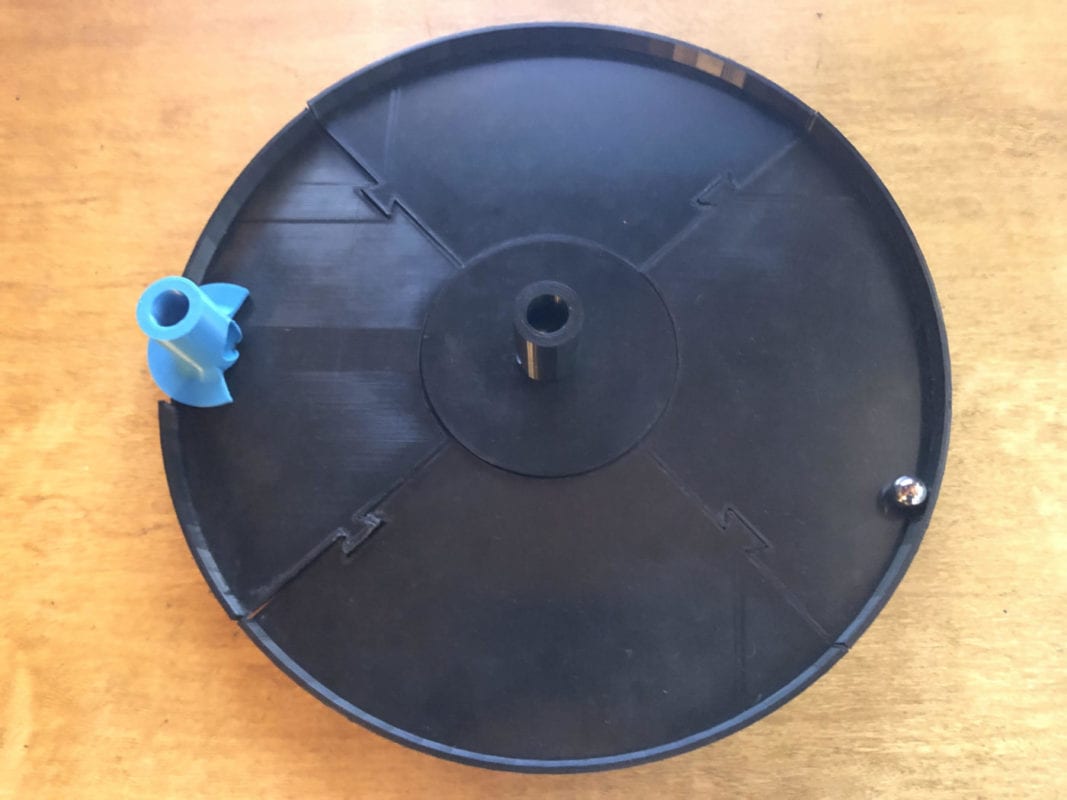

coriolis

The Coriolis activity uses a marble or ball bearing on a spinning wheel to show the Coriolis force in action. The students are able to drop the ball from the center or outside chutes and observe any deflection. The wheel can be spun either clockwise or counterclockwise, allowing for multiple scenarios for the students to build their intuition.

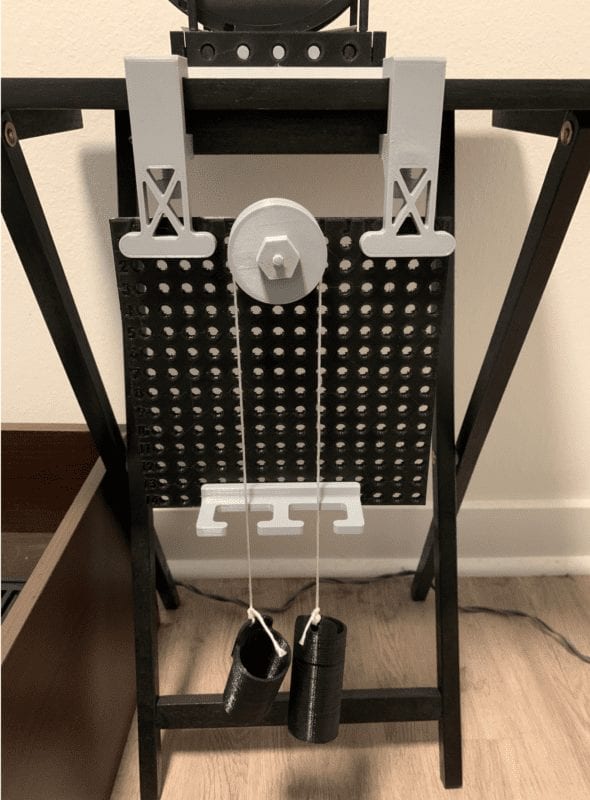

mass-pulley

The Mass-Pulley activity compares differences in masses and net force on system. Students make predictions on which way the mass cups will move verifying with hand calcs.

Manufacturing

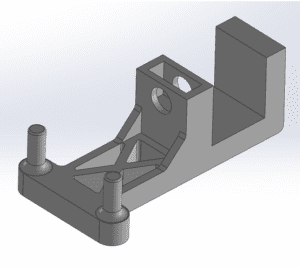

CAD

Each component from every activity was modeled in Solidworks 3D CAD

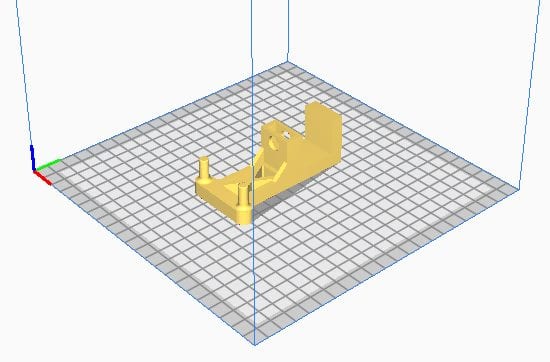

3D PRINT

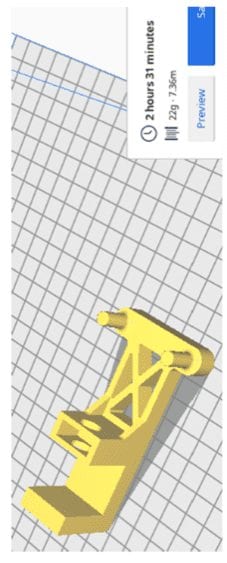

From the model, a STL was generated and uploaded to the 3D printer’s slicing software, Cura, to 3D print

TEST

Each part was assembled, and the functionality and purpose of the components were tested

Tests

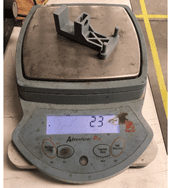

weight

This test verified that the splicing software Cura accurately estimated the mass of printed parts. Cura’s estimates matched an Adventurer Pro scale within +/- 1 gram.

Thus, we used Cura to measure the weight of each activity. All activities meet our criteria of being less than 3 lb.

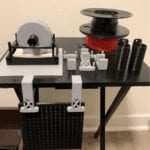

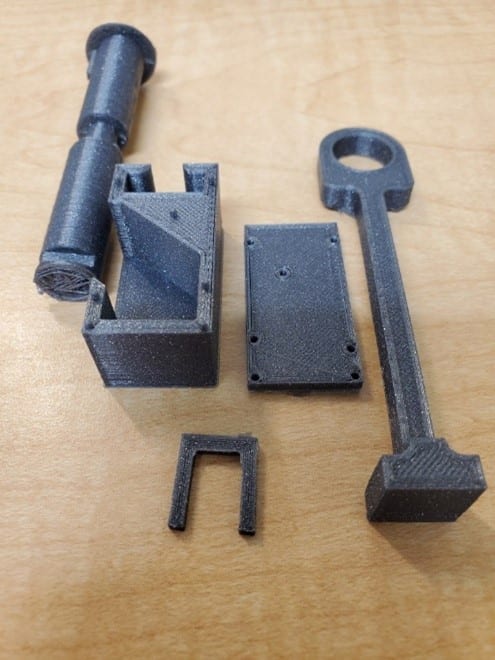

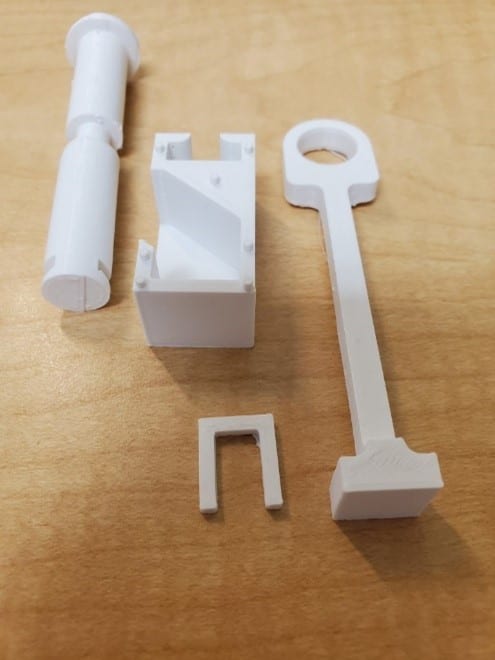

Manufacturability

This test checked whether it was necessary for users to use our recommended settings or if they could use “in house” preferred settings. A personal printer from our team, a printer at Cal Poly’s Mustang ’60 machine shop, and a printer at Cal Poly’s Innovation Sandbox were used.

Printing time was almost the same for all printers and the functional quality was acceptable for each printer and settings used.

The pictures show a set of parts printed on the same printer with our recommended settings and the Innovation Sandbox’s preferred settings.

We concluded that users did not have to use our recommended settings.

Durability

The activities were dropped from a height of 4 ft. to simulate a student accidentally knocking the activity off a desk. No visible damage was found.

Portability

Each activity was placed within a 11″ x 11″ area. The height of the parts was then measured and the volume calculated. We concluded that 9-10 copies of each activity can fit within a 2 ft.^3 area.

modularity

This test was to ensure each activity could be setup in less than 5 minutes. Since the Rollers, Spool, and Mass-Pulley are current activities they were not tested.

Only the AIM activity was thoroughly tested where four students setup the activity for the first time with the following times: 105, 180, 197, 157 sec. Using a Student-t statistical analysis, we can predict that a student can setup the activity for the first time in 2 min. 40 sec. ± 1 min. 4 sec. (95% confidence). This meets our criteria of less than 5 min.