Our Team

Meet the fourth-year Mechanical Engineering students that comprise our team. Go HVAC&R!

Aidan Hays

Renewable Energy Lead

After graduating this fall, I will begin my career as an HVAC sales engineer with DMG North in the Bay Area. I am originally from Seattle, Washington, and I enjoy cooking and golfing.

Samantha Low

ASHRAE Code Expert, Building Modeling

Following the completion of my degree I will be starting my career as a mechanical designer with Stantec as part of their Northern California mechanical team. Originally from Elk Grove, CA I plan to spend the summer exploring national parks and the west coast.

Ryan Sparks

Cost Analyst, Energy Analysis Ast.

I am currently enrolled in Cal Poly’s Blended Master program. Originally from Sierra Madre, California, I will spend the next summer interning for TRC in Irvine before completing my master’s degree concentrating in energy efficiency.

Victoria Vega

Energy Analysis Lead

After finishing my degree at Cal Poly, I plan to work at Glumac as a mechanical designer in Irvine. While I welcome the return to Southern California where I was born and raised, I will miss the beauty of SLO and its many hiking trails.

Acknowledgements

This project would not have been possible without the support of several people. Our team would like to thank our project advisor, Dr. Jennifer Mott, as well as other industry professionals who donated their time: Kameron Beeks for sustainable design component analysis, Gordon Stewart for energy analysis verification, Larry Sun for guidance on project parameters, and Vincent Lai for assistance on project cost estimation.

Our Project Videos

Integrated Sustainable Building Design - Digital Poster

Problem Statement

- This project is a submission to the 2021 ASHRAE Student Design Competition. As buildings are increasingly being designed to help mitigate the effects of climate change, the question of how sustainable buildings perform in different climate regions becomes a very important one. The goal of this project was to develop a big-picture design solution for a higher education, multipurpose building that approaches net zero energy.

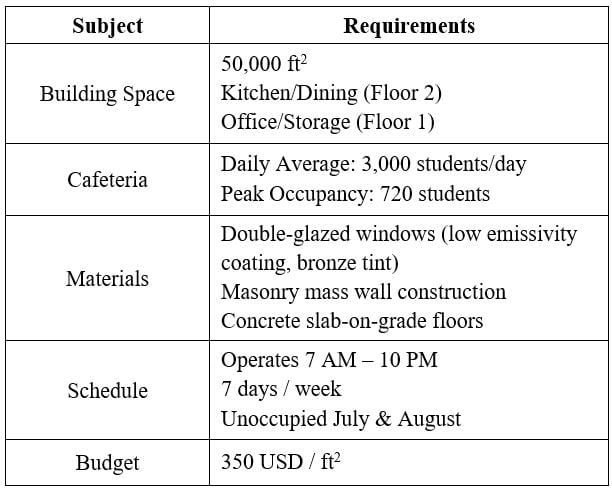

Design Requirements

Design guidelines were given to us concerning building materials, schedules, building use, and budgetary restrictions.

- In addition, our solution was required to meet ASHRAE standards 189.1 and 90.1.

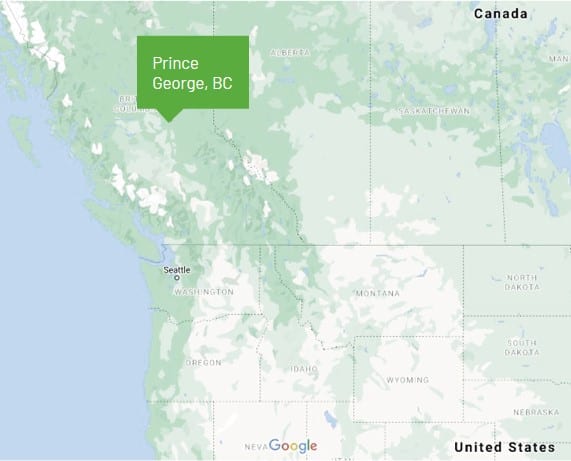

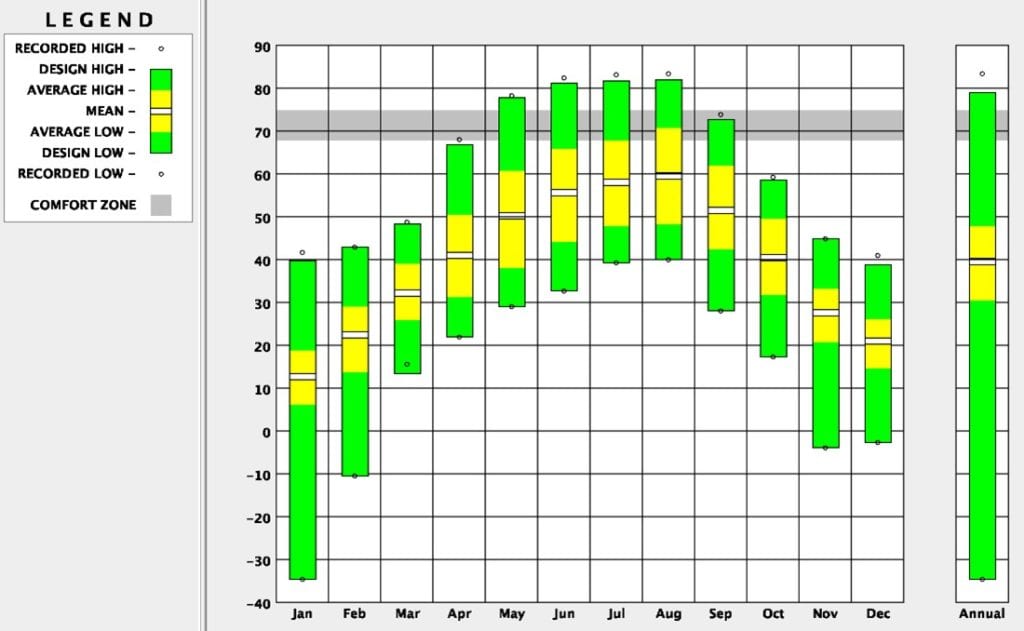

Site Weather

The building is located in Prince George, British Columbia, Canada. This city is classified as ASHRAE Climate Zone 7.

- The average monthly temperature data—plotted using Climate Consultant 6—is shown below. This climate zone frequently experiences below freezing temperatures and is rarely above 70°F.

- The climate data were used as the basis for all calculations, modeling, and decision making.

This project is sponsored by Dr. Jennifer Mott and the Mechanical Engineering Department's HVAC Program.

Modeling

Revit

- A 3D model of our building was designed in Revit. The floorplans, building geometry, and placement of windows and doors were modeled visually.

DesignBuilder

The 3D model was then imported into DesignBuilder, where the materials, schedules, occupancy, and various loads were implemented.

- We then ran simulations to determine the annual energy usage intensity of the building.

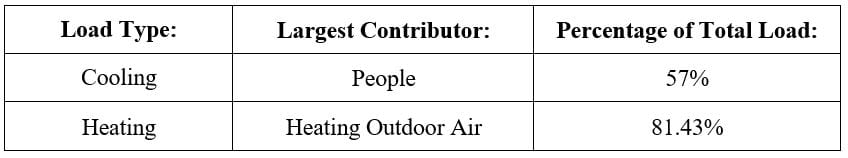

Trace 700

A TRACE 700 model was used to determine the peak heating and cooling loads the building will experience throughout the year.

- In addition to aiding in sizing the equipment in the building, the model helped determine which aspects of the building affected the heating and cooling loads the most.

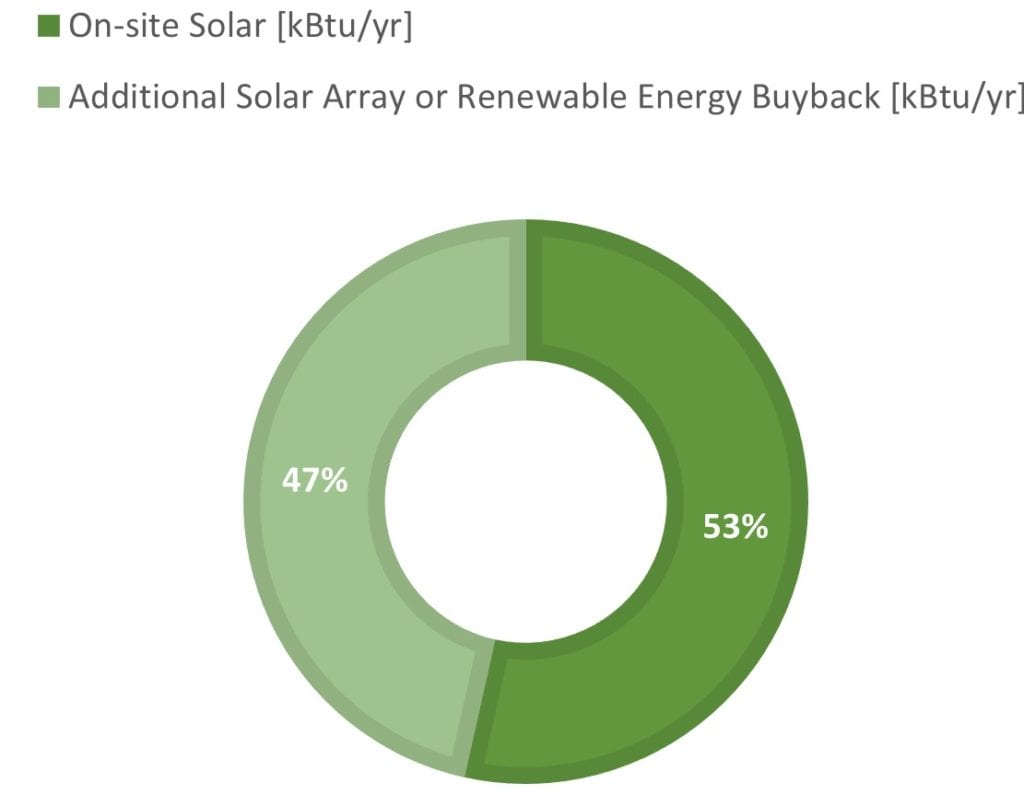

Net Zero

- The building’s solar array will offset over half of the energy used by the building during its first 50 years of operation. The amount of energy produced by this array is exceeds the ASHRAE Standard 189.1 requirement for renewable energy production. If a full net zero approach is desired by the owner, there are two ways we recommend reaching that goal:

An additional, similarly sized, solar array can be placed on another suitable location on the school’s campus.

- Renewable energy can be purchased directly from the power grid at similar costs to building and installing a second solar array.

Design Solutions

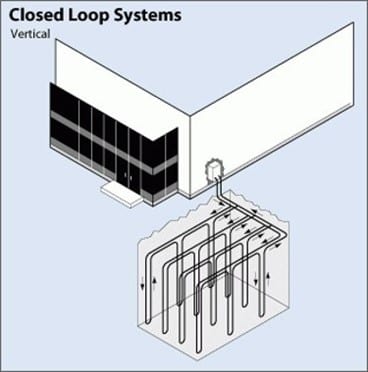

Mechanical Systems

- The low outdoor air temperature can cause the evaporator to operate inefficiently. As a result, a ground source variable refrigerant flow (VRF) heat pump with a dedicated outdoor air system (DOAS) are used to heat the building.

They reduce energy use in the following ways:

- Lower the amount of cold outdoor air required

- Increase the evaporator temperature to 40°F, increasing its efficiency

- Removes energy loss from transferring heat out of the refrigerant

water efficiency

Potable and nonpotable plumbing system design strives for best practices in water use efficiency, specifically focusing on the needs of the kitchen and dining spaces. The following measures ensure the building continues to operate at a high standard.

- Energy Star criteria appliances

- Greywater collection and ultraviolet light radiation treatment

- Drain water Heat Recovery

- Hydronic Systems Controls

Renewables

The building will utilize a rooftop solar array to produce energy. Most of the energy generation by the solar panels will be occur during the summer months when the building is not operational. Therefore most of the solar energy will be sold back to the grid to offset the energy used during the operational months of the building.

- 25,000 ft2 in area

- 5° roof angle

- 89% average efficiency over the 50-year building lifespan

- 1,421,000 kBtu/yr in energy generated

- Offsets 53% of the building’s 50-year energy usage

Cost Analysis

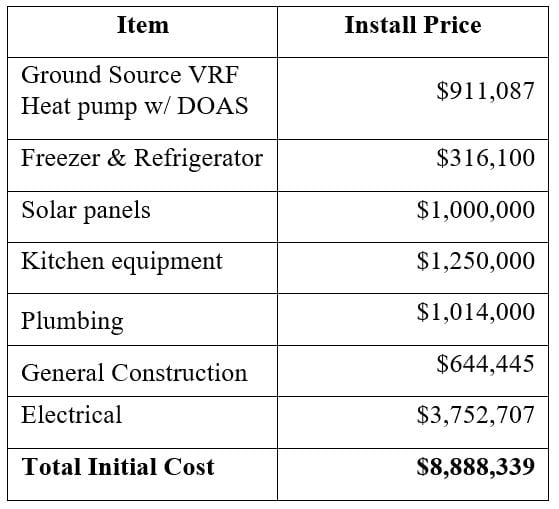

- The full lifecycle cost of the building combines the $8.9 million USD initial cost with the lifecycle cost for 50 years $9.6 million USD for a total price of $18.5 million USD. The majority the lifecycle cost is spent on yearly maintenance and electricity costs.