The Team

Dylan Ell

Dylan Ell is a 4th year Materials Engineering student from Whittier, CA, and he will be graduating in June 2021.

Camden Webb

Camden Webb is a 4th year Materials Engineering student going into the Polymers and Coatings blended Masters Program.

Acknowledgements

We would like to thank iFixit for sponsoring this project, and Brett Hartt, our iFixit contact. We would also like to thank Dr. Lee and Dr. Kivy.

Life Cycle Assessment of an iFixit Pro Tech Toolkit

Problem Statement

Electronic waste, or e-waste, is a particularly harmful waste stream that is generated from the disposal of electronic devices. Extending device life spans is a way to minimize e-waste, and iFixit provides information and tools to help accomplish this. However, consumers do not currently have quantitative data regarding the environmental benefits of repair versus replacement for consumer electronics. The purpose of this project is to perform a life cycle assessment (LCA) to provide quantitative data for the environmental impacts of the Pro Tech Toolkit for the selected impact categories of global warming potential (GWP), energy use, and water consumption.

Life Cycle Assessment

LCAs can be split into four stages: goal and scope, inventory assessment, impact assessment, and improvement analysis. The goal and scope is where the purpose of the study is defined and the decision on what to focus on and level of detail is decided. In the inventory stage, inputs and outputs for the product are determined over the product’s life cycle. Inputs include energy, product materials, and any other component required to produce, ship, use, or dispose of the product. Outputs refer to any by-products, emissions, or waste material that might be released at any stage of the product’s life. Impact assessment uses the data from the inventory analysis to determine environmental impacts of each input and output. From there, improvement analysis targets the most significant contributions to the overall environmental impact in a product’s life cycle to determine the areas with the largest potential for improvement.

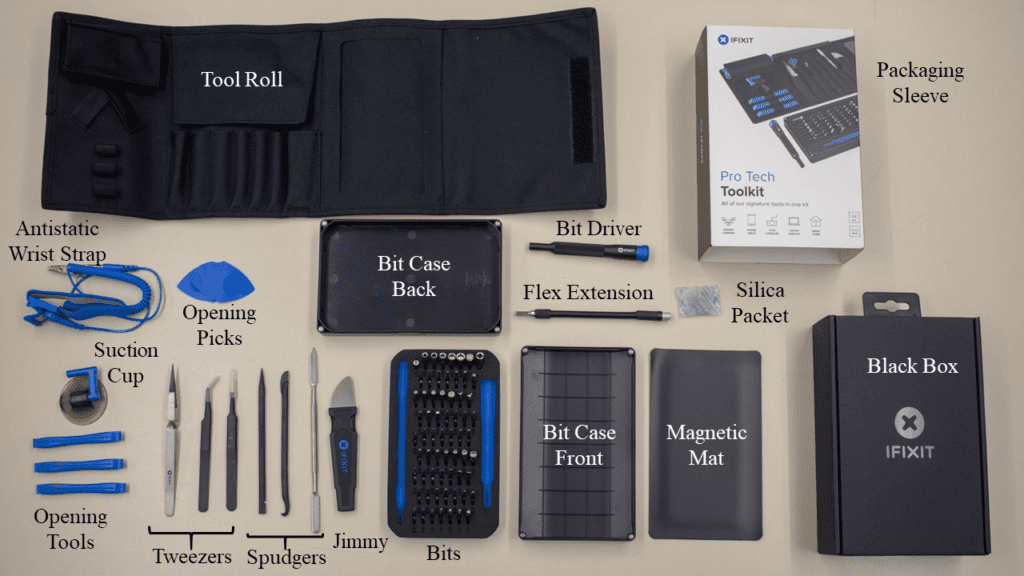

Toolkit Teardown

Each component was separated into subcomponents, organized by its material and processing. The teardown process varied by component; for example, the jimmy was submerged in liquid nitrogen, then cracked open with a hammer to separate the handle from the blade.

Each part of the separated components was weighed three times using a micro-balance, and an average mass between the two Toolkits was used for the final value.

Only two components were unable to be weighed. The aluminum bit driver was comprised of 8 pieces, but the neodymium N45 magnet was unable to be separated from the body. The mass of the magnet was calculated using known dimensions and density.

A calculated value was also used for the anti-static wrist strap, as it was not possible to cleanly strip the entire metal core of the wire from its plastic coating. A smaller section that was stripped cleanly was used to determine a ratio of copper to plastic and this was extrapolated to the total length of the wire.

All other components in the Toolkit were able to be sufficiently separated into their individual materials, but destructive separation required some materials to be measured and added together, such as the bit case back panel, which had to be shattered in the corners.

SimaPro

Assemblies

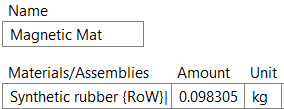

SimaPro was the software used to perform the LCA in this project. Each entry into SimaPro required three inputs: a mass, material, and processing method. The material selections accounted for the primary and some of the secondary processing methods. Using the magnetic mat as an example, the selection for synthetic rubber also included the initial polymer production, extrusion, and vulcanization of the rubber.

Each subcomponent’s environmental impact was evaluated and attributed to the component it belonged to. For example, the jimmy’s handle and blade assemblies were added for the overall impact of the jimmy itself. The “p” refers to part, so in this case the jimmy has two parts, the blade and the handle.

Each of the impact categories were analyzed using characterization models present in the SimaPro database, which were:

GWP – IPCC 2013 GWP 100a, measured with kg CO2 equivalents

Water Consumption – Available WAter REmaining (AWARE), measured in m3

Energy Use – Cumulative Energy Demand, measured in MJ

Methods

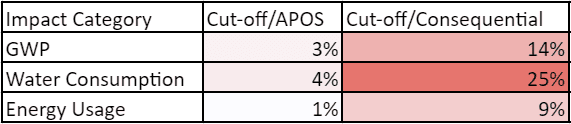

Three methods are available in SimaPro: cut-off, at point of substitution (APOS), and consequential. The primary results were based on the cut-off method, which is geared towards recycled content and recommended for first time practitioners.

Results

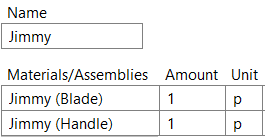

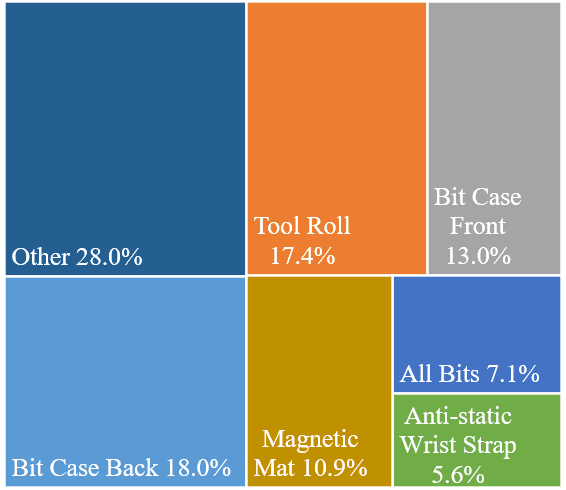

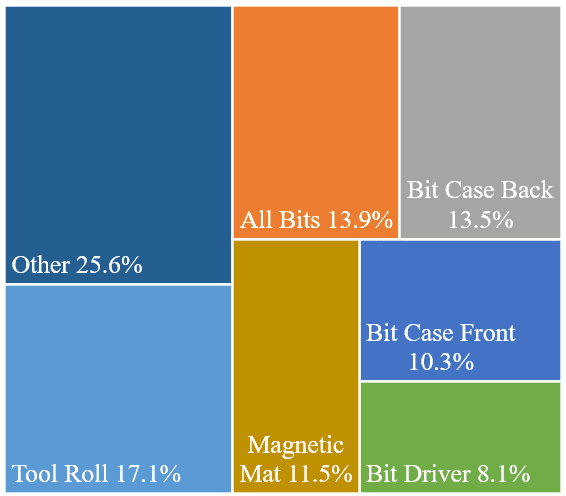

The following graphs highlight the Toolkit components that were the top six contributors to each impact category; all other Toolkit components were combined into the “Other” category. The area of each rectangle shown below corresponds to the magnitude of the contribution of each Toolkit component to the total for the impact category. The fraction of the contribution of each Toolkit component to the total for the impact category is also indicated by the percentage that appears in each rectangle.

GWP

Water Consumption

Energy use

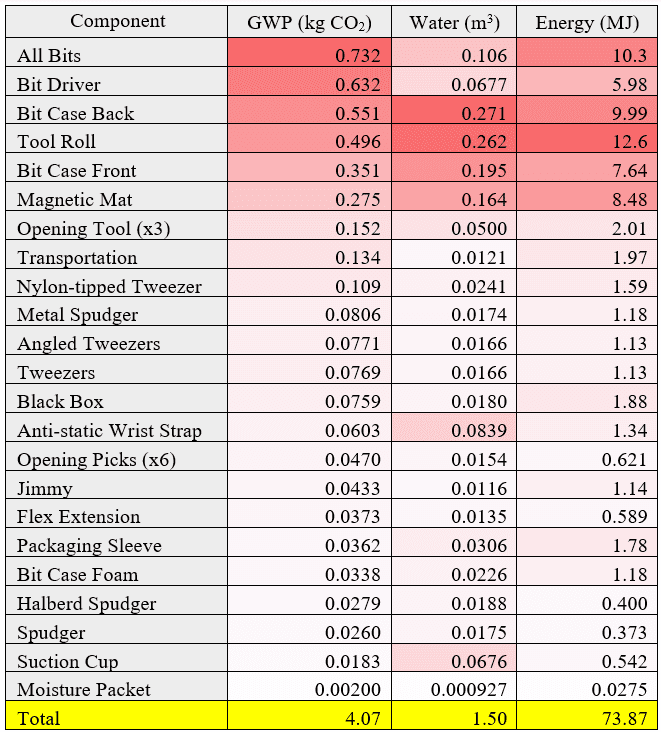

Summary of Results

Aggregating the results for each component’s contribution to each of the impact categories, the following table was constructed with the components sorted by GWP in descending order, where the intensity of the color corresponds to a larger impact:

The table shows the majority of the Toolkit’s impact across categories are from the bits, bit case, bit driver, magnetic mat, and tool roll.

Using the APOS and consequential methods to test for robustness, the total impacts of the toolkit were compared:

Between the cut-off and APOS models, only a 1-4% difference was calculated. Between the cut-off and consequential models, a 9-25% difference was observed.

Common Phone Repairs

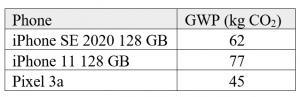

In addition to the Toolkit, repair should also consider the impact of the new part. Two of the most common phone repairs involve a screen replacement and a battery replacement. Environmental information about phone production was only available for the GWP.

- Production: 4.07 kg CO2

- Production: 3.5 kg CO2

- Saved: 38-71 kg CO2

- Production: 12.5 kg CO2

- Saved: 29-61 kg CO2

Future Considerations

Choices used during initial material selection should be further considered to ensure the best selection is chosen from the database for each given method. For example, the opening picks and opening tools were made out of polyoxymethylene, but this material was not contained in the SimaPro database. Nylon 6 was contained in the database and was used as the substitution material selection for those tools because of their similar properties and secondary processing, but further research into the structure and primary processing between the materials could more robustly determine if Nylon 6 is the closest substitution in the database. Additionally, while each component had at least one processing method incorporated, additional secondary processing methods (specifically those involving the combination of two or more materials) should be considered for each component to make sure all steps of production are addressed properly.

The largest potential for improvement in the environmental impact of the Toolkit lies in the choice of material and processing used for the bits, bit case, bit driver, magnetic mat, and tool roll.

.

This project is sponsored by iFixit