Our Team

Chris Bruni

Chris is a Mechanical Engineering Major, with experience in mechanical design utilizing 3D CAD software as well as performing detailed engineering analysis from classes taken at Cal Poly. In addition, he has experience with product design and development from a previous internship.

Jose Gomez

Jose is an Electrical Engineering Major, with a background in designing circuits and code that drive mechanical systems obtained through various Cal Poly labs. He also has a small background in science of materials from multiple classes on the topic and participating in a nano materials project for the Naval Post Graduate School.

Taylor Morris

Taylor is a Mechanical Engineering Major and has previous design experience from mechanical engineering classes taken at Cal Poly, as well as some manufacturing process knowledge from courses taken for her manufacturing concentration. She also has industry project management experience from two summer internships.

Cole Pike

Cole Pike is a Manufacturing Engineering Major, with relevant experience in design for manufacturing principles in additive and net shape processes and 3D CAD modeling. Other relevant experience is in design of experiment principles, statistical quality tools, and product/process design.

Acknowledgements

We would like to thank our project sponsor, Angel Avila, and our advisor, Jim Widmann, for all of their support throughout this experience.

Our Project's Digital Poster

Problem Statement

Veterans’ Affairs home care nurses currently spend anywhere from thirty minutes to two hours filling out monthly prescriptions one pill at a time to veterans who are unable to leave their homes. The goal of this project was to create an easy-to-use device that could be left at a patient’s home that nurses could use to quickly and accurately dispense medication into the patient’s monthly pill box.

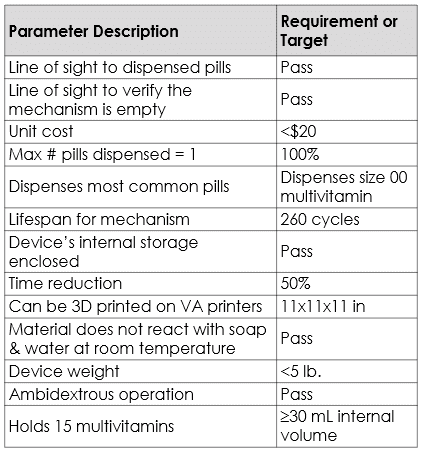

Requirements

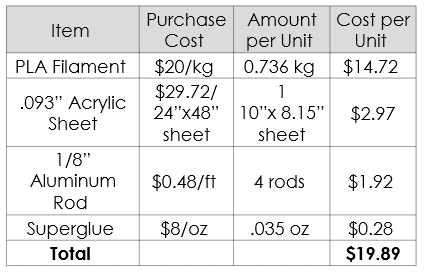

Cost

This project is sponsored by Angel Avila of the

Santa Fe Veteran's Affairs Office.

Final Design

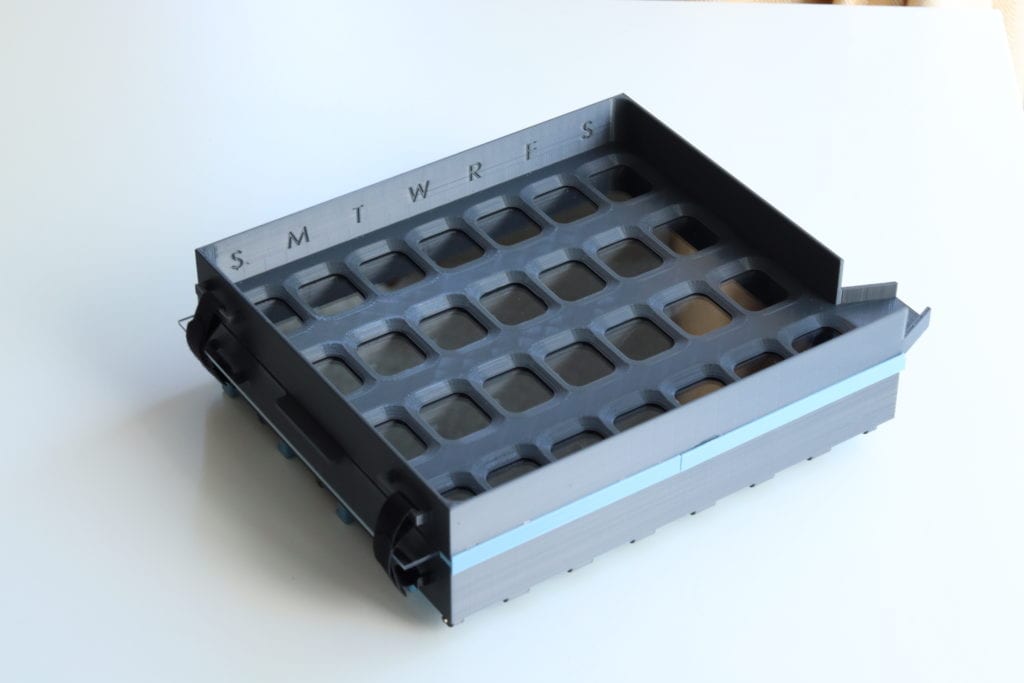

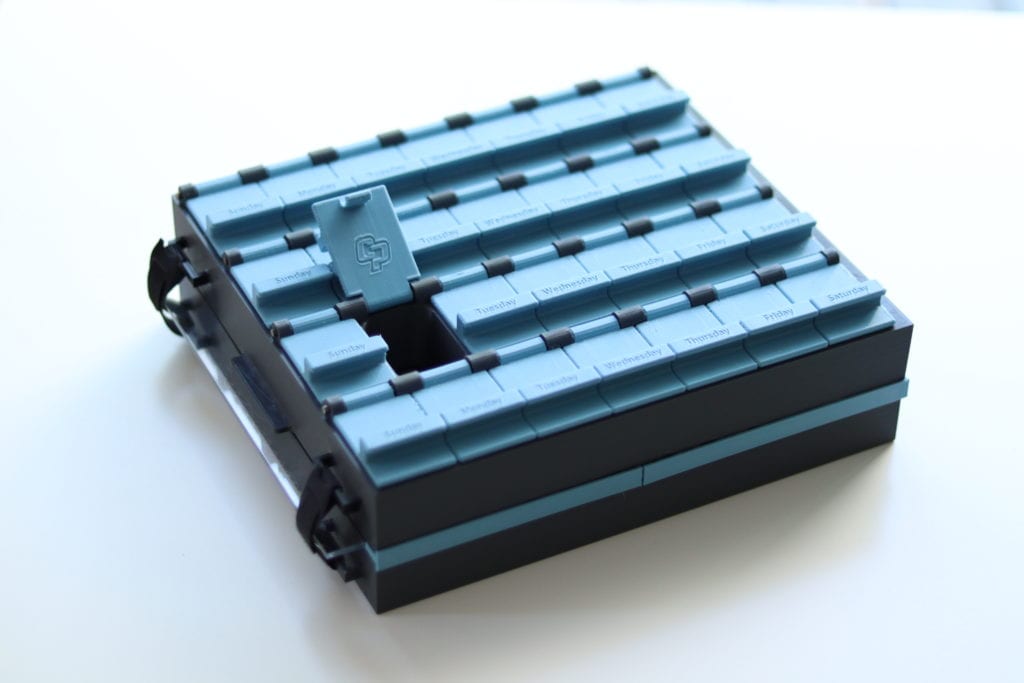

This device integrates a patient’s monthly pill box (top left image) with a sorting tray for the nurses to use to distribute the month’s pills. The device is used by pouring the pills onto the sorting tray (top right image), then using your fingers to move one pill onto each slot. If there are any excess pills, they can be removed by placing the opening of the pill bottle to the end of the funnel (bottom right image) and sliding the pills into the bottle. Then, removing the acrylic sheet in the middle of the device allows the pills to fall into their designated pill boxes.

Testing

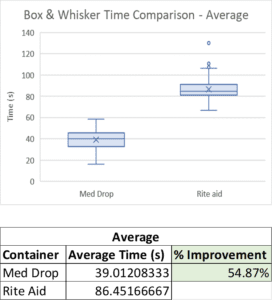

Testing was completed with consistent pills with our sorting tray vs a commercially available pill container. 48 trials were completed by each person comparing the two devices. The average percent improvement was 54.87%.

Cycle tests were also performed on our lid design to ensure that the lids would be able to endure the 260 cycle engineering requirement. 10 lids were opened and closed 520 times each and no signs of damage were visible.

Manufacturing

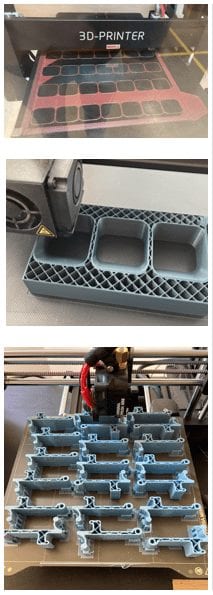

This device was almost entirely 3D printed. The sorting tray, pill boxes, sliding rails, and lids are all printed separately. The hinge pins were cut to size using bolt cutters, and the acrylic sheet was cut to the desired shape via laser cutting. It is assembled using superglue to adhere the sorting tray and pill boxes on either side of the sliding rails, and the lids are attached via the aluminum hinge pins. The total time to print the pill boxes, sorting tray, sliding rails, and 28 lids is approximately 57.5 hours. Gluing all the parts together and attaching the lids takes about 20 minutes.

Conclusion

This project resulted in an easy-to-use device for VA home care nurses to quickly distribute their patients’ monthly medication. The device satisfied all engineering requirements and received high praise from our sponsor. Currently, the time trials we performed show a 54.87% improvement over the nurses’ current medication distribution method. As 3D printing is not an ideal manufacturing method for high production volumes, future work requires manufacturing tooling for injection molding so the VA will be able to mass produce these devices.

Our Project's Videos

The following videos should be replaced by embedding the link(s) from your own YouTube video channel. Please DO NOT upload video files directly to WordPress.