The Team

Behind every successful project, there is a hard-working team. Meet the students behind the Scitechatorium’s newest exhibit, The Oscylinderscope!

Esther Hurst

Team Captain

Esther is a fourth-year mechanical engineering student with a passion for arts & crafts, hiking, and spending time with her loved ones. She has plenty of experience working in hands-on design/manufacturing through her lead position in Cal Poly’s Supermileage Vehicle Club and her employment on-campus as a machine shop technician.

Felipe DeJesus

SolidWorks/ Structural Lead

Felipe is a fifth-year mechanical engineering student concentrating in mechatronics. He grew up in Atascadero and chose Cal Poly for its prestigious (and local) engineering program. Felipe’s interest was piqued in the SciTechatorium by the opportunity to give others the formative experiences he had as a child interested in STEAM. When he is not doing schoolwork, you can find Felipe around SLO county climbing and mountain biking

Emma Salam

Documentation and Accounting

Emma is a fifth-year mechanical engineering student from Tacoma, Washington. She grew up skiing and figure skating but has enjoyed living in San Luis Obispo for the access to beautiful trail and surfing locations. Emma chose mechanical engineering due to her love of physics and creative design. Emma is the second oldest of five sisters. She has worked at skating and wilderness camps and is excited to help kids learn in a hands-on way.

Nejad Harara

Sponsor Contact

Nejad is a fifth-year mechanical engineering student. He is a Bay Area native and one of four siblings. During his free time, he loves being outdoors and spending time with his family and friends. The SciTechatorium Interactive Display senior project interested him because of his love for youth education and creative expression. Having been a youth counselor for many different STEAM based summer camps, Nejad has the background to understand what it takes to teach children new concepts in exciting ways.

Acknowledgements

The team would like to recognize and give a warm thank you to our incredible project advisor, Dr. Mohammed Noori, and our wonderful sponsor, Christian Strauli. Thank you both for your time, advice and support. We are better engineers because of you. Special thanks to Chris Harrington at Ernie Ball for your guidance in helping us find the correct guitar strings for our exhibit. Thank you to all the Cal Poly Mustang 60 shop technicians for your guidance and expertise. And thanks to all of the senior project students who offered valuable feedback on our designs, reports, and final prototype.

Our Project Video

The Oscylinderscope

Problem Statement

The Bellevue-Santa Fe Charter School’s SciTechatorium needs a new way to attract K-6 students to explore STEAM concepts. Our solution should complement existing exhibits while adding new, collaborative, hands-on learning to the space. The exhibit must engage users with learning experiences that are fun, interactive, and encourage further exploration, because as the Bellevue motto goes: “what we learn with pleasure, we never forget.”

Design Criteria

The following criteria guided the team’s design decisions as we developed our prototypes and final design.

- Safety:

- The design should not invite misuse or provide unnecessary hazard.

- User Engagement:

- The educational aspects should be age appropriate.

- Collaboration:

- Students should be inspired to collaborate and work together while exploring the exhibit.

- Accessibility:

- Users of any mobility level, including those in wheelchairs, should be able to interact with the exhibit.

- Maintainability:

- Exhibit must be maintained for no more than $50 per year, and maintenance should be prioritized when designing for failure modes.

- User Enjoyment:

- Design will embody the BSFCS motto, “What we learn with pleasure we never forget.”

- Manufacturability:

- Design must accommodate the extremely limited shop time available.

Ideation and Modeling

Existing Exhibits:

To create a holistic learning experience, the team decided to create an exhibit that meshed well with the exhibits already in the SciTechatorium. The museum currently contains multiple exhibits focused on sound and music, and the students take a class to learn to play guitar.

The walk-in guitar design was not chosen due to manufacturing limitations imposed by COVID-19 and limited shop access. The team moved forward towards an easier-to-manufacture concept.

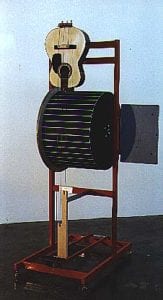

The Oscylinderscope was originally created by Norman Tuck and showcases sinusoidal waves in plucked guitar strings. Our design adapts Tuck’s exhibit to include bass strings and a simpler wooden frame.

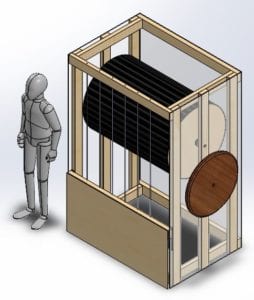

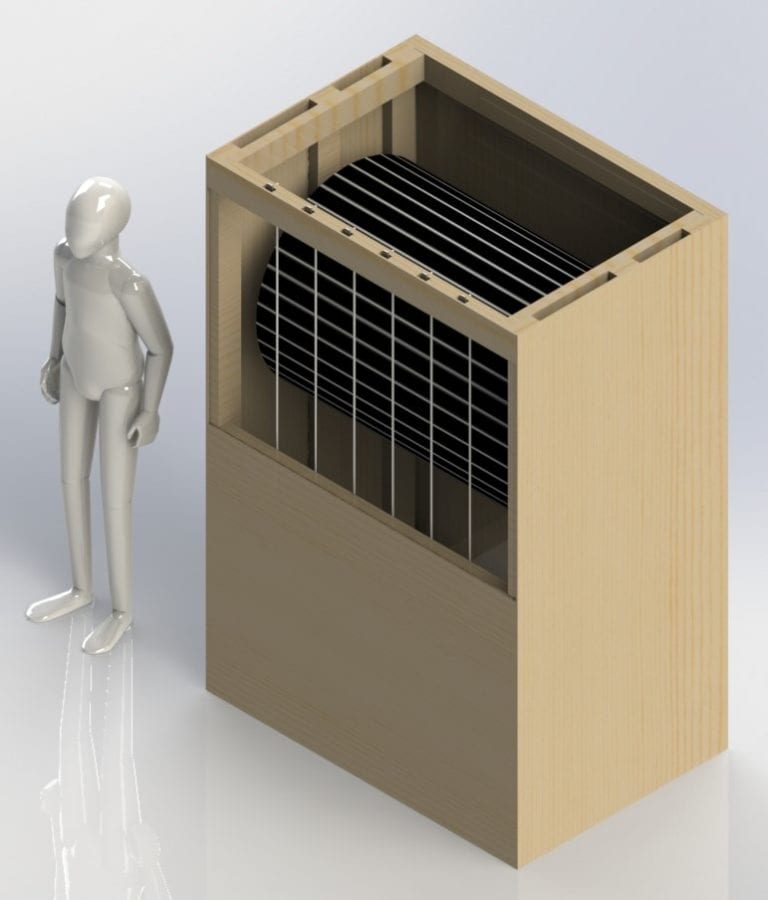

Below is the team’s earliest prototype of our Oscylinderscope, featuring an external hand wheel, gear reductions, and plexiglass sides. For reference, the character in the render is four feet tall.

Sponsor: Bellevue Sante Fe Charter School

Final Design

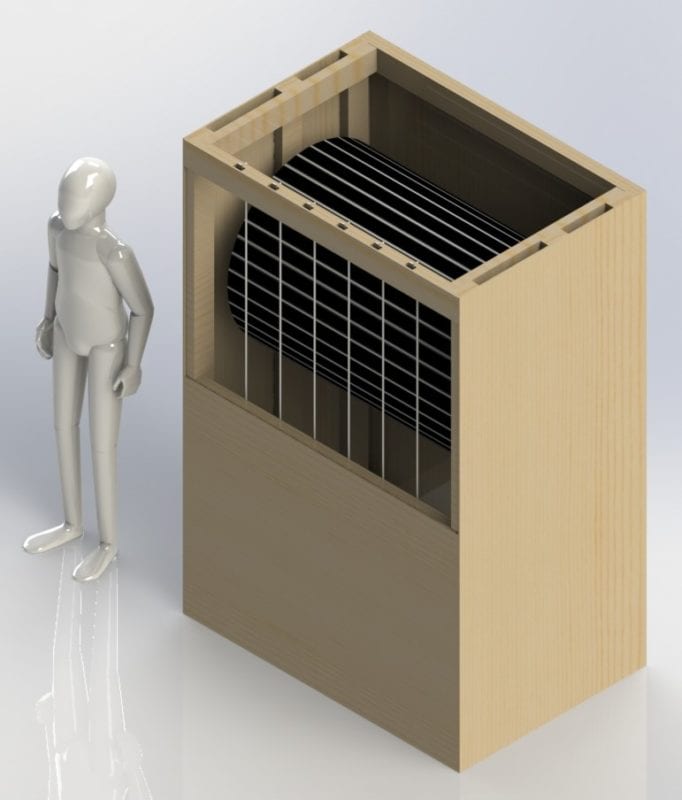

This rendering shows the final SolidWorks model of the Oscylinderscope. The mannequin in the image is roughly 5′ tall.

This CAD model allowed for dimensions of various components to be finalized and aided in determining tolerances necessary for manufacturing and assembly.

Function Visualization

Mechanical Details

Tensioning of the string is accomplished using standard guitar tuning hardware.

Tuners are placed at the top of the exhibit (6′) to prevent students from accessing them.

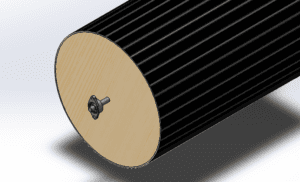

The Osclinderscope is connected to a stainless steel axle using shaft collars and supported by flange bearings.

Axle and bearing sizing was performed by Esther Hurst who used conservative estimates to perform stress and life-cycle analysis.

Calculations & Analysis

Tension Calculations

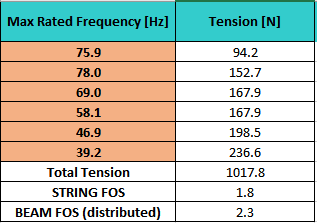

To determine the amount of tension present in each string, we used the following equation:

$T = 4*m*L*f^2$

Using this equation, we were able to calculate a rated frequency (f) for each string based on mass (m), length (L), and rated tension (T).

With the table above, an operator can easily ensure that the strings are tensioned to the proper level using a guitar tuner.

Testing

The Oscylinderscope will be used, on average, daily by 20 students. Its target audience is students between the ages of 5 and 12. The exhibit was tested on critical design aspects to verify:

Testing Results:

Noise

- The exhibit does not create dangerous levels of noise.

Durability

- Components are robust and can withstand the wear and tear of user testing and design troubleshooting. Bearings have been lubricated and a new set of bass strings have been installed prior to sponsor hand-off.

Tipping

- The use cases the team considered during testing did not lead to tipping. Just in case, a 50-lb sand bag designed to rest on the bottom supports of the exhibit will eliminate any potential of this hazard.

Cleaning Accessibility

- The most touched surface, the cylinder, is easily cleaned using disinfectant wipes. Polyurethane coating was used to protect high-wear surfaces from damage caused by cleaning agents.

User Testing

- During user testing, the overwhelming response was positive and enthusiastic. Especially after the simplification of the design from earlier versions, points of interaction were made clearer and users were easily fascinated by the visuals the exhibit creates. Many users asked questions after interacting with the exhibit, which shows user desire for further exploration, fulfilling one of the team’s main design goals.

- All in all, testing indicates that the exhibit is successful by all design parameters. The exhibit is engaging and interactive leaving users with exploratory questions about the illusion and waves. No user misuse occurred during testing, which was important to our safety mitigations. The design is intuitive and users easily understood the proper and safe points of interaction.

Moving Forward

One of the biggest challenges we faced on this project was getting access to the Cal Poly Machine Shops. Due to COVID-19, shop access was restricted to adhere to social-distancing safety guidelines. In addition, all team members were not residing in San Luis Obispo until campus began to reopen in spring quarter. Because of these hurdles, some of the original exhibit design’s functionality was omitted. If the team had more time, here’s what we would want to improve:

- Create a mechanism that allows students to modulate the tension in the strings

- Add hinges to the walls to make maintenance access easier

- Perform actual user testing with students from the SciTechatorium

- An external hand wheel to spin the drum

- Painted educational materials and sponsor acknowledgments