Our Team

Our team is made up of four mechanical engineering students, each of which is concentrating in HVAC&R. For our senior project we chose to participate in the ASHRAE Applied Engineering Challenge.

Blake Matsuura

Load

Analyst

My name is Blake Matsuura and I am a fifth year Mechanical Engineering student from Thousand Oaks, California. I was initially inspired by my father, who is also a mechanical engineer, to study this major. In the future, I hope to pursue work involving graphics modeling and systems design.

Mary Kelly Ogan

Plumbing Designer

Hi! I’m Mary Kelly from a small central coast town called Lompoc. I am currently finishing up my Mechanical Engineering degree and have just recently completed my minor in music. Post-graduation I plan to move to San Jose and work for United Mechanical Inc. as a HVAC design engineer and hopefully transition into a project management position down the line.

Zack Peterson

Expense

Analyst

My name is Zack Peterson and I am from a small town in the East Bay called Brentwood. I am a fourth year Mechanical Engineering student and after graduation I will begin my career as a Control System Programming Engineer at Automated Solutions Group in San Jose. I have loved my time at Cal Poly and I am very excited to take what I have learned in school and apply it in industry.

Dean Smith

HVAC

Designer

My name is Dean and I am a fourth year Mechanical Engineering student concentrating in HVAC&R. I am from the mountains in Colorado and following graduation I will be moving back to Avon, CO to work with BG Buildingworks as a mechanical systems designer. My interest in HVAC&R sparked at my internship with BG Buildingworks and I look forward to the future challenges that come with designing building HVAC and plumbing systems.

Acknowledgements

Thank you to the HVAC department and ASHRAE for giving us the opportunity to participate in this competition for our senior project. Thank you to Adrian Giovanco for taking time out of his busy schedule to meet with us and guide us through some necessary design considerations. Additionally, a huge thank you goes out to Dr. Jennifer Mott for her continued support and advice throughout the course of this project.

Project Video

Digital Poster

Project Description

Problem Statement

The ASHRAE challenge involved designing an indoor farm that is no larger than 4000 square feet within a single-family residential building to sustain the occupants. The design must consider temperature and humidity control as well as lighting, noise, and outer environment factors.

Project Scope

-

Scope

Description

Location

San Luis Obispo, California

Target Customer

Single Family Residency

Building Footprint

≤1000 square feet

Additional Design Goals

Utilize Solar Energy and Natural Lighting

Plant Information

Plant Conclusions:

- Goal: Select temperature range for several plants including lettuce, carrots, potatoes, tomatoes, cucumbers, corn, squash, peanuts, beans, basil, thymes, mint, rosemary, sage, clove, lemongrass, and artichoke.

- Result: Maintain temperature range of 65°F – 75°F year-round

Concept Design Process

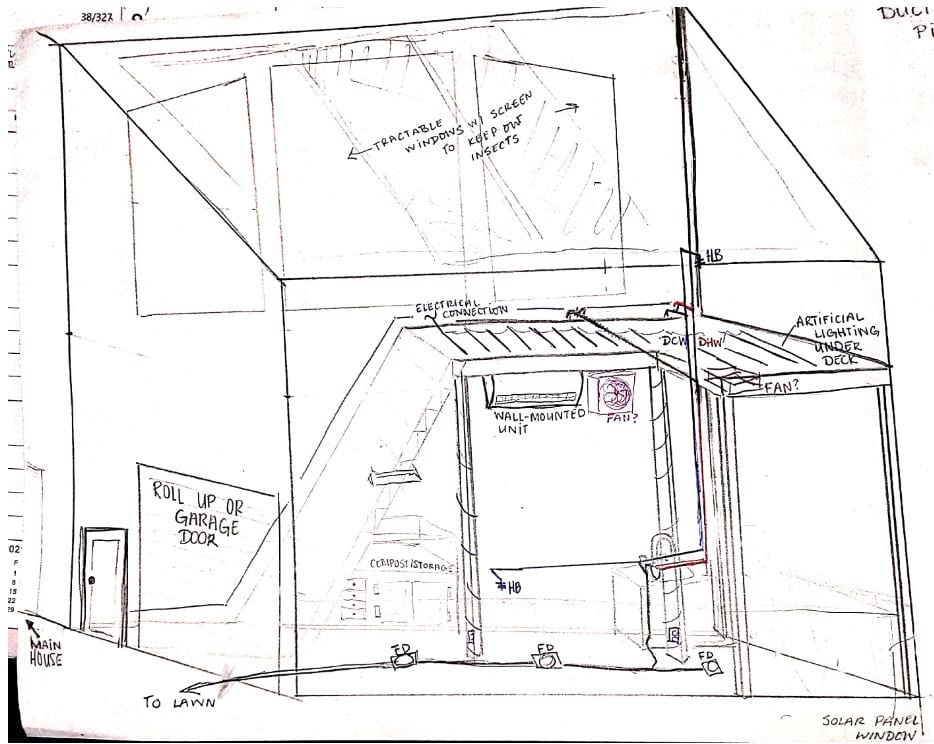

Hand Sketch of Building Concept Design

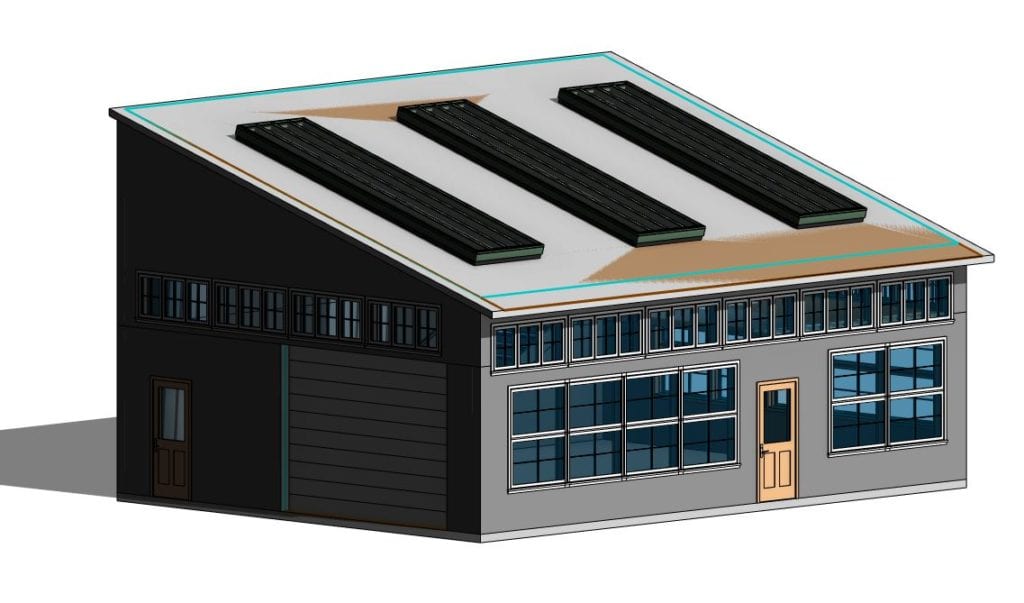

Preliminary CAD Model

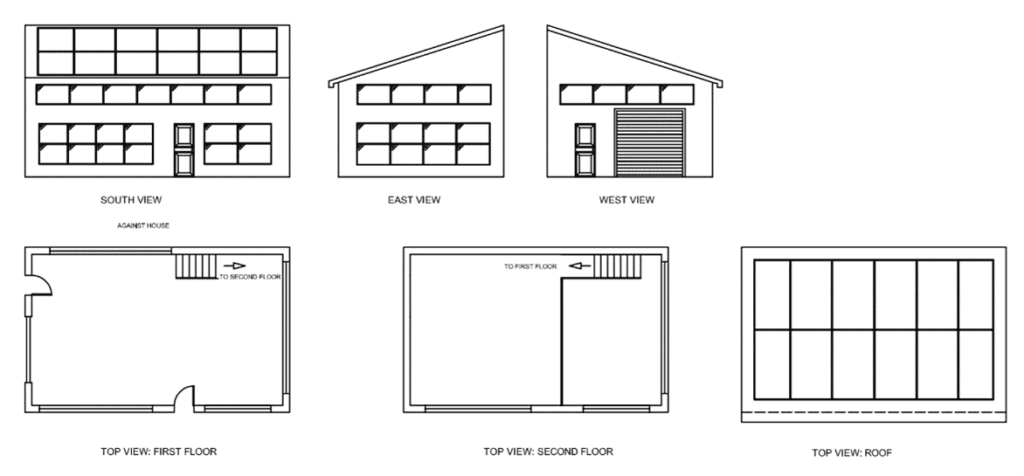

CAD Layout of Preliminary Sketch. Built in AutoCAD.

This CAD model allowed for area takeoffs and calculations to produce necessary loads from climate data and internal requirements. Calculations were completed in TRACE 700 Program.

ASHRAE/Setty Family Foundation

This project is the Setty Family Foundation: 2021 Applied Engineering Challenge

Location Analysis

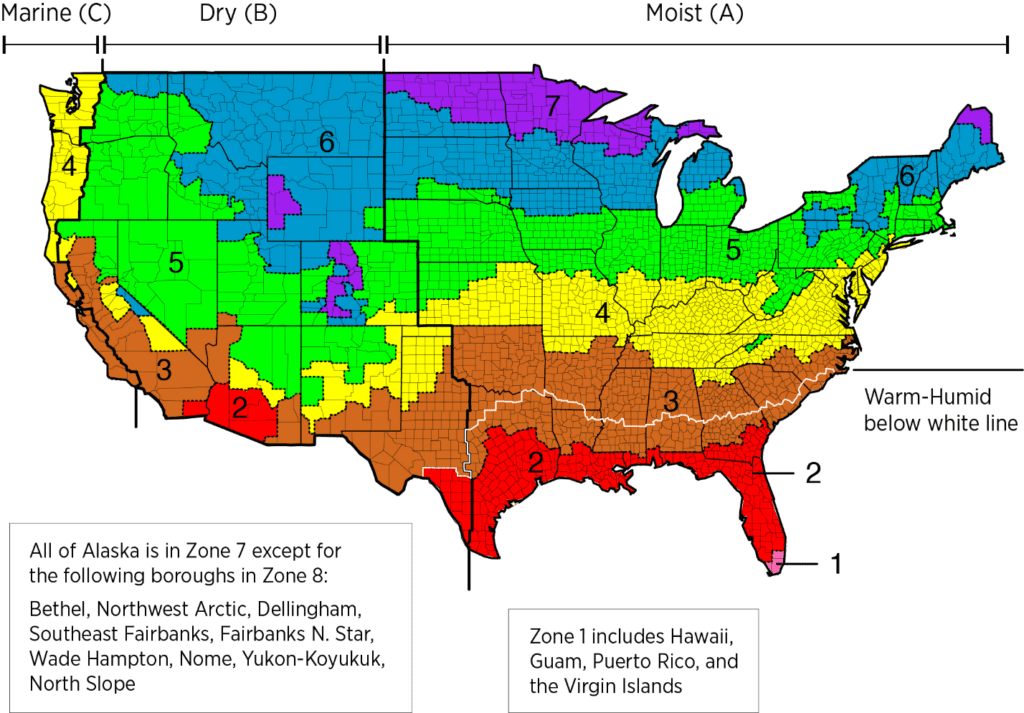

IECC Climate Zones in United States

Location/Project Details

Residency Type: Single-family residencies are more common in the San Luis Obispo area and as such, this facility type was considered to be more applicable to the community.

Climate Zone: Based off the above map provided by IECC, San Luis Obispo County is within the Marine Zone 3, and as such, building constructions and requirements were applied when finding the building loads.

Required Building Codes: The county of San Luis Obispo uses the 2019 California Title 24 energy codes as their residential standards for all buildings and as such the requirements for the building design were adhered to those outlined in the codes.

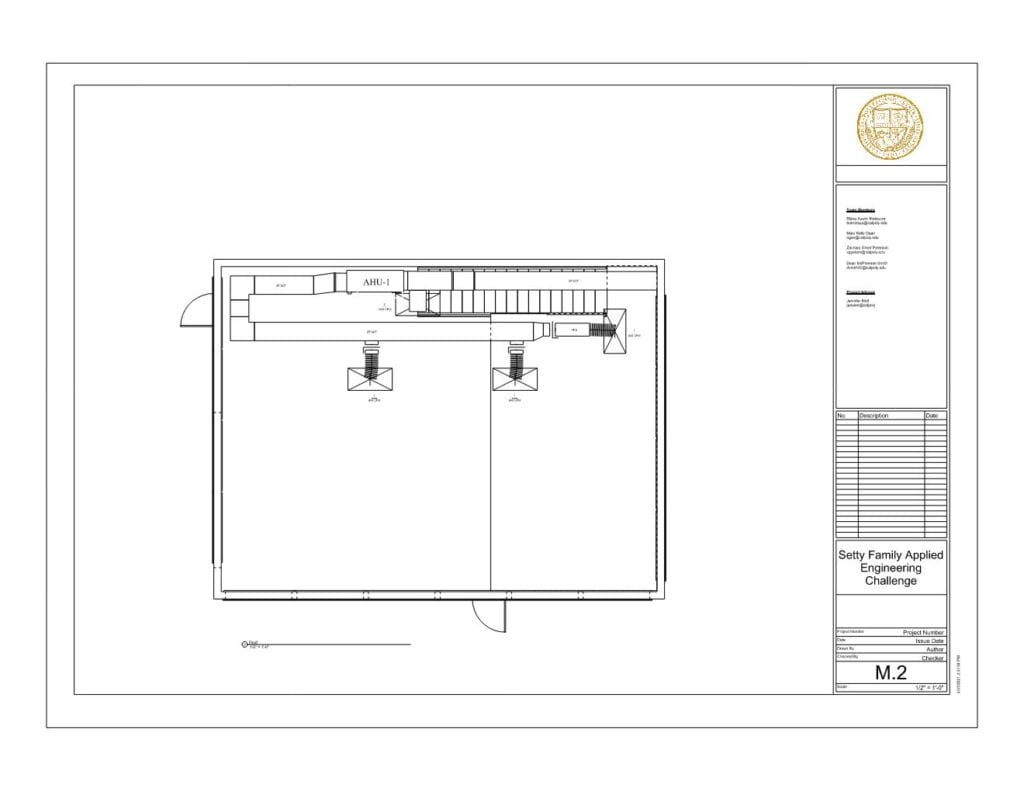

Example Construction Document

Mechanical Plan Produced from Final Model

Mechanical Equipment

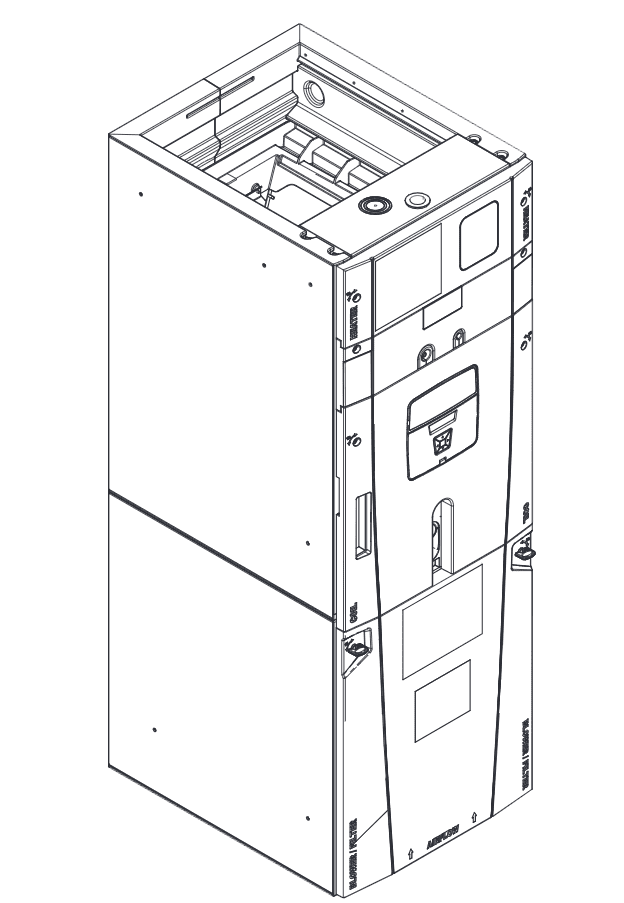

Air Handler TAM9A0C60V51DA from TRANE®

Condensing Unit 4TTV0060A1000A from TRANE®

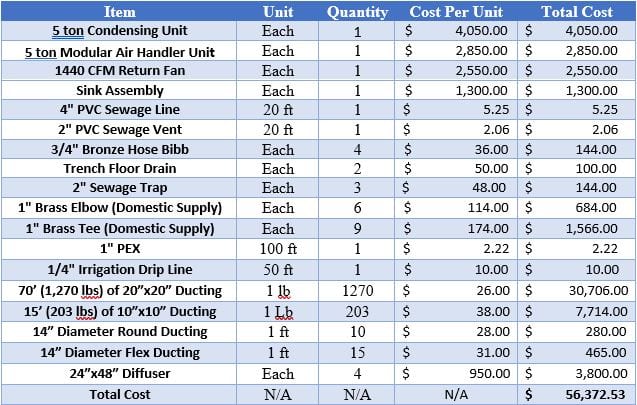

System Pricing

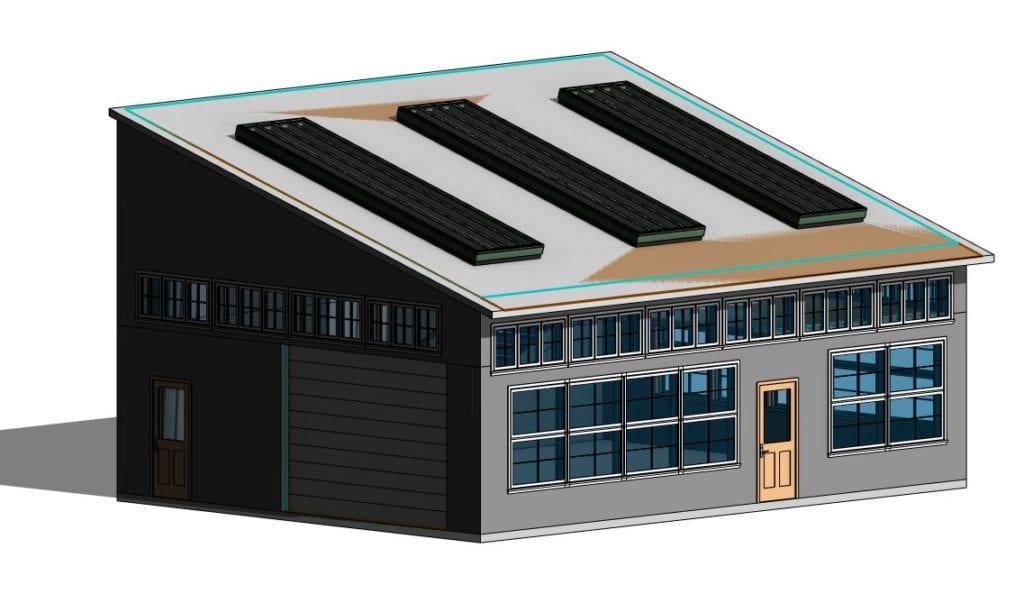

Finished Model

Final Building Model Rendering

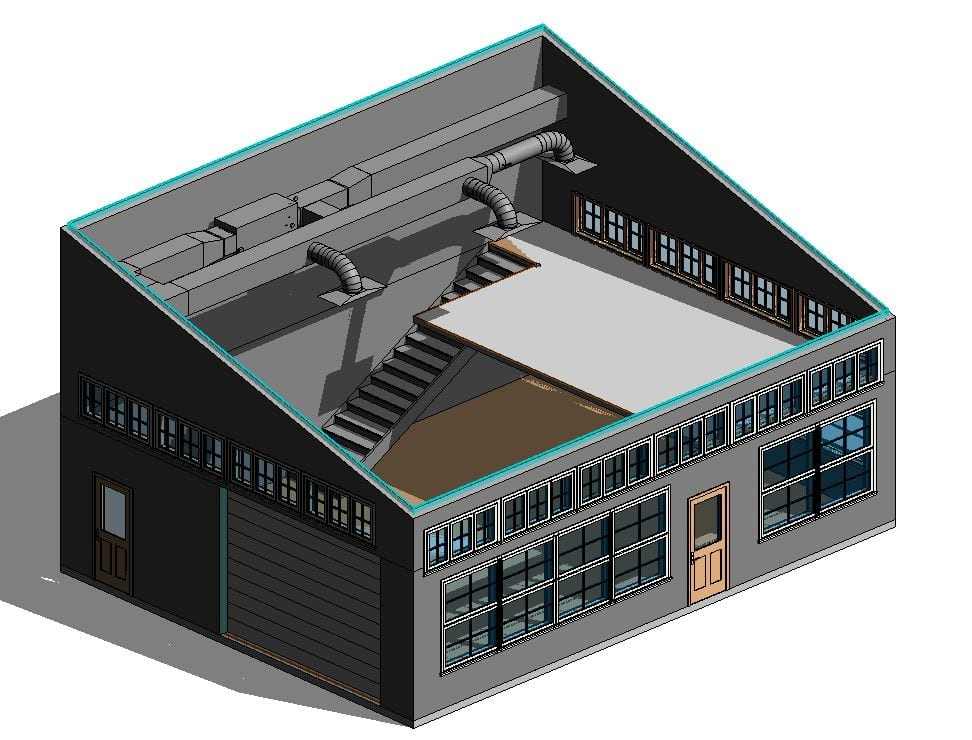

Upstairs HVAC System Model Rendering (Exhaust fan not shown. Located below upstairs section)

Design

Architecture:

To maximize use of the space, the grow room is two stories, with the second story being a balcony space. The balcony space can be used by the tenants as a casual dining area while still affording room for flora and fauna. There are several windows to allow plenty of natural light into the space and provide an aesthetic appeal. Also, thanks to a shared wall between the main part of the home and the grow room, all power supply and plumbing connections can come from inside the home.

Lighting:

The power supply from the main part of the home allows for easy wiring to the grow space for lighting. Artificial lighting is important to help the plants grow to their fullest potential. Additional overhead lighting is important for safety and convenience to the residents.

The plumbing supply connections also come from the main part of the house. This includes the domestic hot water and cold water. The hot water will only be used for the industrial sink whereas the cold water will go to the sink, hose bibbs, and irrigation. The sewage system will be independent since it will drain to the lawn outside of the grow room.

HVAC:

The airside system design was based on the cooling and heating loads from TRACE 700. TRANE equipment for the air handling unit and associated condensing unit were selected using the information from the calculated results. An exhaust fan was also selected per the required ventilation rate from the load calculation. While there is an ASHRAE requirement in ASHRAE 62.1, the resulting calculation when compared to the TRACE results showed that the load calculations provided a more conservative size to select the fan with.