Our Team

We are the VIBE Senior Project Team, including Angela Colabella, Molly Rodda, Emma Neal, and Joey Chen.

Angela Colabella

Industrial Engineer

Angela was responsible for the cost-estimating, manufacturing, and production planning for this prototype, as well as serving as the primary point of contact with the project sponsor. Angela will be graduating with a B.S. in Industrial Engineering and a minor in Italian Studies. After graduation, Angela will continue her studies at UC Berkeley pursuing a master’s degree in Industrial Engineering & Operations Research.

Molly Rodda

Mechanical Engineer

Molly was responsible for the overall mechanical design of the VIBE fit-widget bracelet. This included choosing the materials, 3D CAD designs, assembly, and testing of the bracelet band, the interchangeable icons, and three versions of the interchangeable fidget toys. Molly will be graduating with a B.S. in Mechanical Engineering, and she is actively looking for a company to start her career in Engineering.

Emma Neal

Electrical Engineer

Emma was responsible for the electrical systems of the VIBE fit-widget bracelet. This included circuit schematics, PCB production and assembly, testing, and implementation. Emma will be graduating with a B.S. in Electrical Engineering and a minor in Music. Following graduation, she will begin working as a field engineer, doing contracting work for PG&E.

Joey Chen

General Engineer

Joey was responsible for the research of the fidget element and the engineering drawings shown below. He will be graduating with a B.S. in General Engineering. He plans on looking towards engineering jobs in the entertainment field after graduation.

Acknowledgements

We would like to thank our sponsor David Postula and our advisor Karla Carichner for their guidance and support throughout the design process over the past year. We could not have done it without you!

Project Videos

The following videos should be replaced by embedding the link(s) from your own YouTube video channel. Please DO NOT upload video files directly to WordPress.

Project Videos

The following videos should be replaced by embedding the link(s) from your own YouTube video channel. Please DO NOT upload video files directly to WordPress.

Project Poster

Background

SPONSOR

The sponsor of the VIBE fit-widget bracelet is David Postula. His vision for the bracelet was to create a fun and useful tool to help children with anxiety and restlessness.

problem statement

Many children and teens need a way to focus, relieve stress & anxiety, and channel their energy in the classroom as such feelings can prevent them from performing at their best.

Objective

Our goal was to create a wearable focus tool for young students featuring a fidget element and a thoughtful reminder icon. The bracelet must be classroom-friendly and provide an outlet for the user to release energy while improving focus on daily tasks.

Requirements

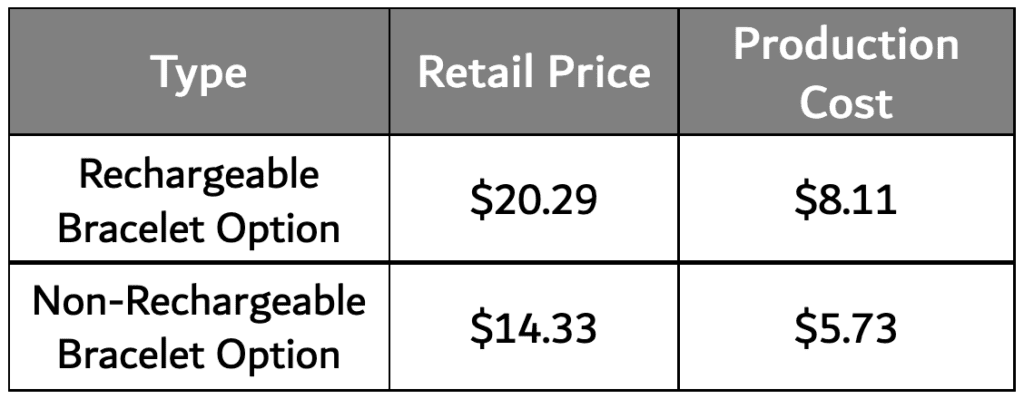

- • Low-cost design: retail price of $10-$20

- • Vibration reminder element for intermittent reinforcement throughout the day

- • Multiple timing intervals for vibration reminder

- • Fidget feature for energy release

- • Adjustable band to accommodate wide age range of 5 to 15 years old

- • Interchangeable personal icon for user customizability

- • Classroom-friendly

- • Kid-friendly

- • Aesthetically pleasing

- • Comfortable for daily wear

- • Durability to withstand a child’s daily routine

Pricing and Cost

The VIBE team designed 2 different prototypes, one with a rechargeable battery and one with a non-rechargeable battery. As shown above, the non-rechargeable option fits well within the cost requirements. However, in mass production, it is believed that the rechargeable option will fit within the cost constrains providing a more reliable and efficient product.

The VIBE Fit-Widget Bracelet

This project is sponsored by David Postula

Mechanical Design

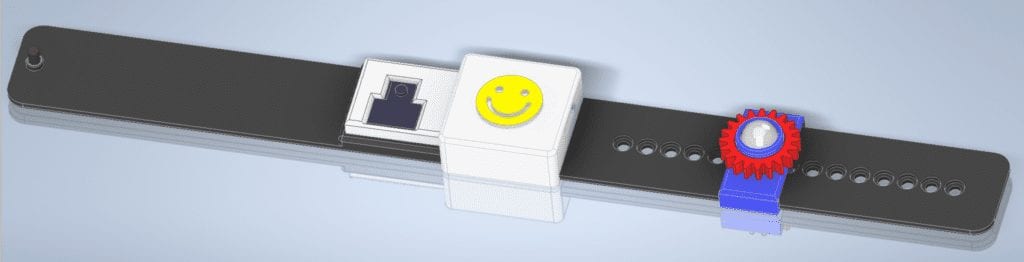

The mechanical design of the VIBE bracelet consists of a TPU band designed for 15 different wrist sizes, an interchangeable TPU icon, and a interchangeable fidget toy. The design is meant to provide the customer with customization and comfort.

Fidget Toy Element

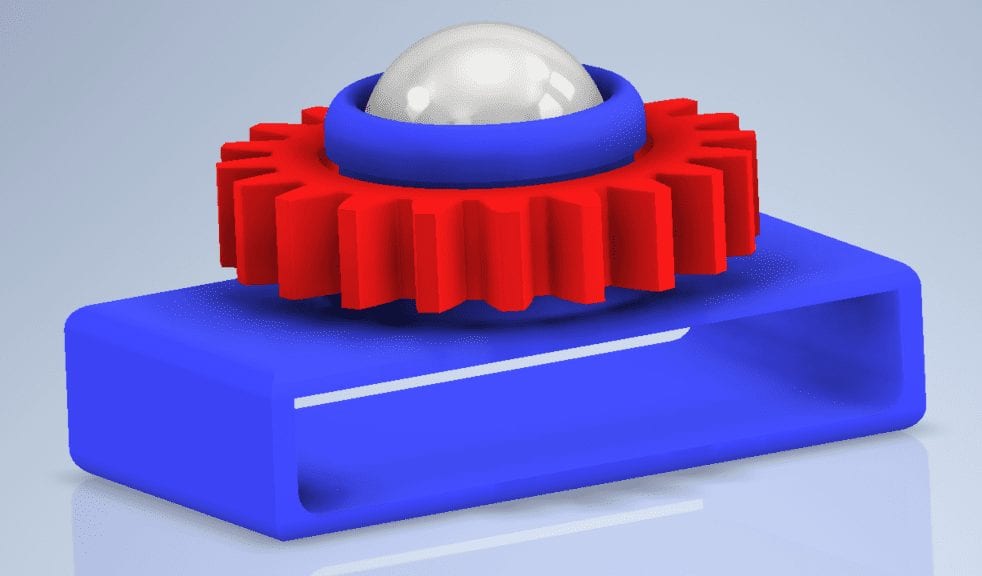

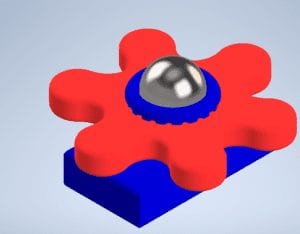

These 2 fidget toys are examples of possible fidget elements on the band. The toy on the left consists of a smooth gear with a roller ball in the center. The toy on the right is a slight modification, with a haptic feedback spinner with a roller ball in the center. Both fidget pieces are options for the prototype VIBE bracelet.

Reminder ICON Element

These 2 icons are examples of possible designs for the interchangable/customizable icon of the band. The goal of the icon is to have a personal and meaningful visual symbol for the user. With a simple icon design, there is potential for any number of customizable designs.

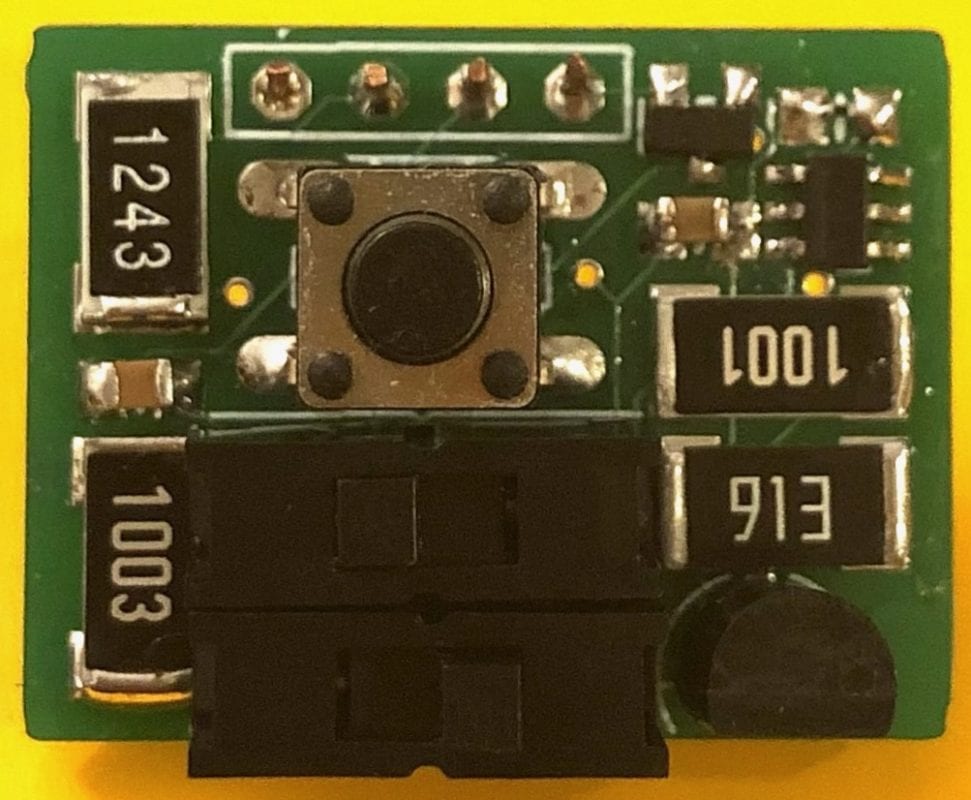

Electrical Design

The purpose of the electronics system is to turn on a vibration motor at a set time interval to give the user physical feedback. The vibration will draw the user’s attention to the icon placed on the bracelet band and therefore be an effective reminder system.

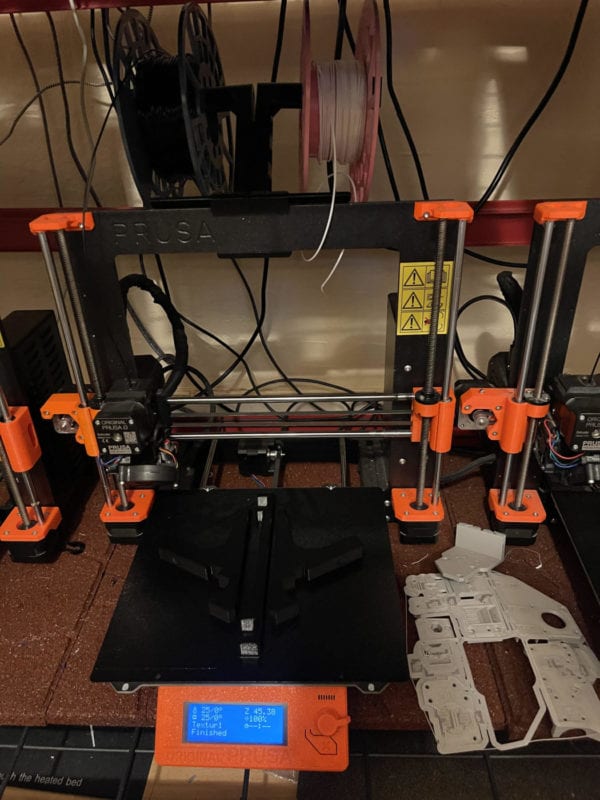

Manufacturing

The band, icon, and fidget element were all manufactured through 3D printing with TPU.

The custom PCB was manufactured using a PCB fabrication manufacturer called JLCPCB. The assembly of the board and wiring between components was completed by the VIBE team.

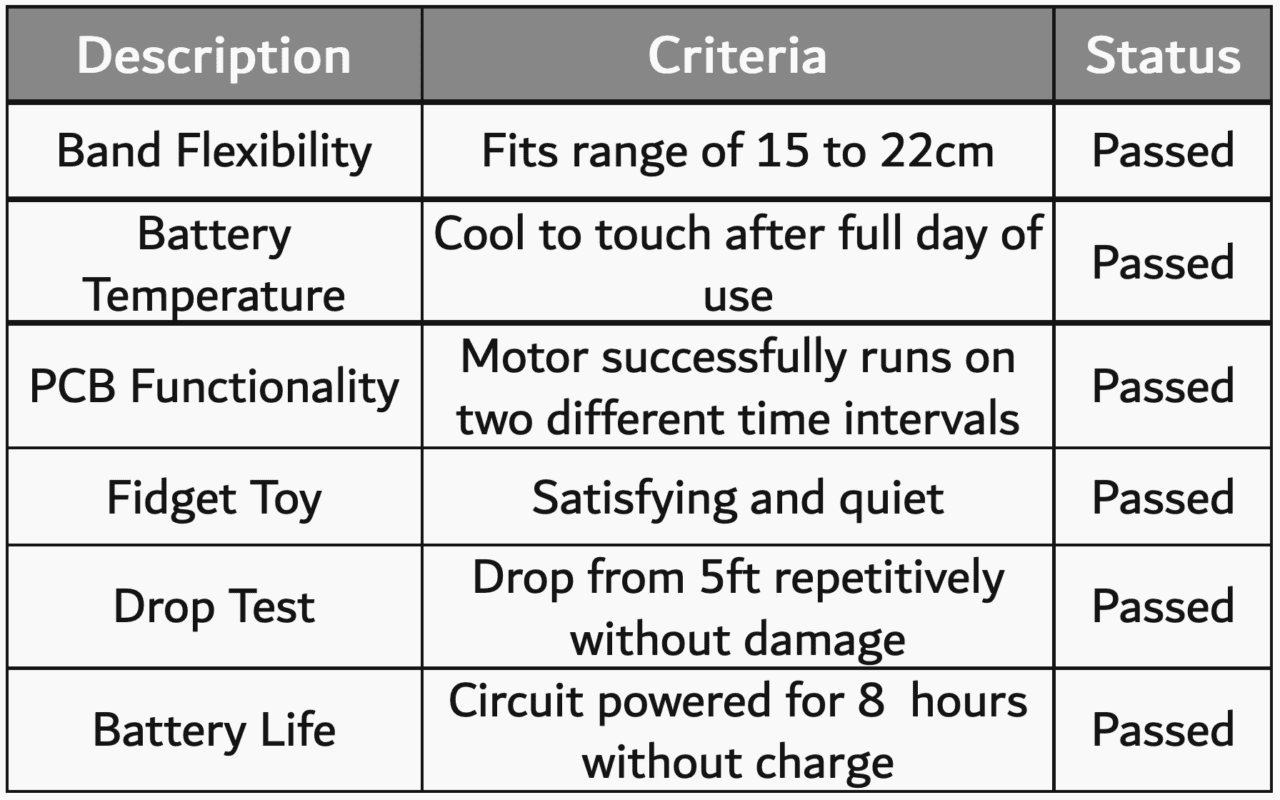

Testing

The testing of the VIBE bracelet centered around comfort, durability, and functionality. After many prototype iterations, the designed bracelet was able to withstand repeatedly dropping from 5ft or higher, constant bending and twisting, and changes in adjustability. The electronics system was functional after running for a full day many days in a row, the battery lasted more than 8 hours of the day, and the vibration motor consistently went off at the correct time (whether 30 minutes or 1 hour). With the completion of these tests, the prototype met all of the design requirements proving to be a successful design.

Conclusion

The final prototype designed by the VIBE team is adjustable, customizable, and lightweight to maximize comfort and appeal. The band is over-designed in some areas due to 3D printing limitations. Future developments include injection molding, downsizing, designing more fidget/icon elements, increased waterproofing, and testing with children.