Our Team

Amanda Almada

Mechanical Engineering

Amanda is a fourth-year Mechanical Engineering student. She had an R&D Engineering internship at Medtronic, where she worked on the design and development of neurovascular stents. She is interning at Cepheid this summer as a Component Engineering intern. After this summer, she has one more quarter until she graduates and then she hopes to get a full-time job in the medical device industry.

Jae De Leon

Biomedical Engineering

Jae is a fourth year Biomedical Engineering student with a mechanical design concentration. He is starting Cal Poly’s biomedical masters program in fall 2020. He enjoys going to beaches, kayaking, and and working out. After school, he plans to go on a long tropical vacation before pursuing a full-time job within the medical device industry in the bay area.

Miles Curtis

Manufacturing Engineering

Miles is a General Engineering student focusing on Manufacturing Engineering and entrepreneurial design. Next year he plans to paraglide, surf, and work part time in a machine shop.

Clare Lupo

Biomedical Engineering

Clare is a fourth-year Biomedical Engineering student with a concentration in Mechanical Design. She will be back at Cal Poly next year to pursue her master’s degree in Biomedical Engineering. She enjoys hiking and painting in her free time, and hopes to have a career helping people through the development of medical devices.

Acknowledgements

Thank you to the Quality of Life Plus Organization, our challenger Cassie Perando, our sponsor Vanessa Salas, our advisor Dr. Lily Laiho, Jon Monet, Tim Bump, and everyone else who has helped us this year.

Our Project Videos

QL+ Farming Prosthetic for Cassie: Digital Poster

Project Description

Challenger: Cassie is a Navy Veteran who lost her arm between her elbow and shoulder a couple of years ago. She currently works on a farm in Oregon where she performs manual labor on a day-to-day basis. She came to QL+ because her current prosthetic doesn’t meet her needs related to her work on the farm.

Proposed Solutions:

- Clamping Terminal Device

- Bracing and Screw Holding Terminal Device

Background

Cassie uses a body-powered prosthetic arm that uses hand attachments (terminal devices) to perform specific functions. The project objective was to build two terminal devices to help with her farming tasks.

Design Constraints

Clamp

- Length: 6 inches

- Weight: 0.25 lbs

- Clamping range: 0-3 inches

- Lateral stiffness of grip: 0.05 inches

- Maximum clamping force: 250 lbf

- Attaches to current adaptor

- Feature to attach cable

- Cassie assessment: comfort and efficacy

Brace/Screw Holder

- Length: 6 inches

- Weight: 0.25 lbs

- Stabilizing and driving screw size 1.5”-3”

- Attaches to current adaptor

- Feature to attach cable

- Cassie assessment: comfort and efficacy

Manufacturing Plan

*Manufacturing halted due to COVID-19 pandemic. Plan outlined below will be passed on to future QL+ team to complete.

Clamp

| Material | Manufacturing Plan |

| 7075-T651 Aluminum | Main shape cutout: waterjet, on-campus machine shops Detailed geometry: CNC machining, on-campus machine shop |

| Off the shelf components | Assembled with spring, hardware, and off-the-shelf barrel adjuster on campus |

Brace & Screw Holder

Material | Manufacturing Plan |

7075-T651 Aluminum | Main metal body: CNC machined, on campus machine shop |

Adhesive for rubber/metal connection | Order 3M Neoprene High Performance Rubber and Gasket Adhesive 1300 |

Rubber | 1) 3D print external mold with QL+ printers 2) Pour rubber mix into external mold until hardens 3) Wait for rubber mix to harden, then remove from external mold |

This project is sponsored by Quality of Life Plus (QL+)

Design Features

Clamp

- Quickly adjustable clamping range

- Four-bar linkage provides mechanical advantage

Brace & Screw Holder

- Right angle surface in rubber padding grips and holds construction boards for the application of power tools

- Magnetically holds screws steady for easy driving

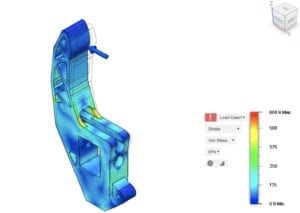

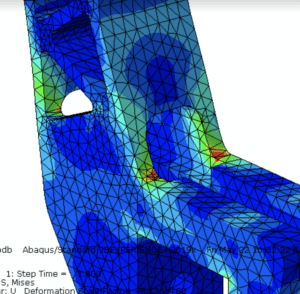

FEA Stress Analysis

The design was iterated based on FEA stress analysis of the main jaw.

Stress was originally concentrated at the inner fillet of the main jaw.

Based on the FEA analysis, the fillet radius was increased to reduce the stress concentration.

Prototype Assessment

Brace & Screw Holding

Prototype sent to Cassie was assessed based design and usefulness. Scored highly on metrics for usefulness and design. Next iteration adjusts angle of attachment to prosthetic adaptor to be parallel with body of device.

Clamp

Cassie had few critiques for the clamping device and prototype scored high on almost every metric. Next iteration modifies feature used to attach cable to fit larger diameter ball.

Final Design

Clamp

The purpose of this device is to allow Cassie to grasp and clamp down on objects such as wood boards. She will have a strong grip and a clamping range of 0” to 2.5”.

Brace & Screw Holder

This device will allow Cassie to brace material for the application of power tools and to hold and stabilize screws. The magnetic slots will allow her to hold 1.5”-3” long screws firmly enough to start them into material with a power drill.

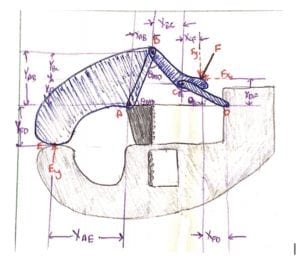

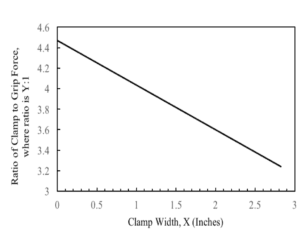

Clamp Force Analysis

A MATLAB script was created to calculate the clamping force created with the geometry of the linkage designed for the clamp terminal device.

An equation shows how the clamp width (X) affects the ratio of clamp to grip force (Y). This equation is plotted and can be used to estimate the clamping force generated from any initial gripping force and at any clamp width between two locked positions.

Conclusions

- While these devices were designed specifically for Cassie, they have the potential to be useful to many people

- Cassie is very excited about these designs and their potential to help her in her daily life

Recommendations for Future Work

This project is ready to be passed on to a future group to complete manufacturing and testing:

- The clamp will require iterative manufacturing and fine-tuning to achieve a perfect fit for testing and use

- The brace & screw holder is ready to be manufactured and tested