The railroad boys

Joshua Giacone

I am a 4th ME graduating in Fall 2020. I am from Long Beach, CA. My hobbies include: surfing, pc building/gaming, camping, and hiking. I am hoping to find work within the construction industry when I graduate.

Matt wieland

I am a 4th-year mechanical engineering student graduating this spring. After graduation, I will be returning to Reno Nevada where I will be working for an HVAC&R consulting firm.

Zack allen

I am a 5th-year mechanical engineering student from Danville, California graduating this spring. I will be returning to the Bay Area to work for an HVAC&R consulting firm and continuing my swimming career outside of work.

Acknowledgements

Thank you to our former professor, Larry Sun, and Andres Lujan from DMG for their time and advice on this project. Their insight and experience regarding HVAC&R system selections were instrumental in the development of this recommendation. We would also like to thank our professors Steffen Peuker, Ph.D., and Jennifer Mott, Ph.D., for guidance through our ME HVAC&R student career.

Our Project Videos

Railroad Project Process and Results

History

Swanton Pacific Railroad is a historical site that Cal Poly Alum Albert B. Smith (Al) created to store his 1915 Panama-Pacific steam locomotives and equipment. Al built the Swanton Pacific Railroad on his Davenport ranch and today it stands as an operational memorial to him through the help of countless volunteers. The current rolling stock on the ranch includes three 1/3 scale Pacific-type steam locomotives that were built for the 1915 Panama-Pacific International Exposition, along with a diesel switcher locomotive and passenger/maintenance railcars. Events are held throughout the year where rides are offered to the public while the tracks and locomotives are in safe conditions.

Problem Statement

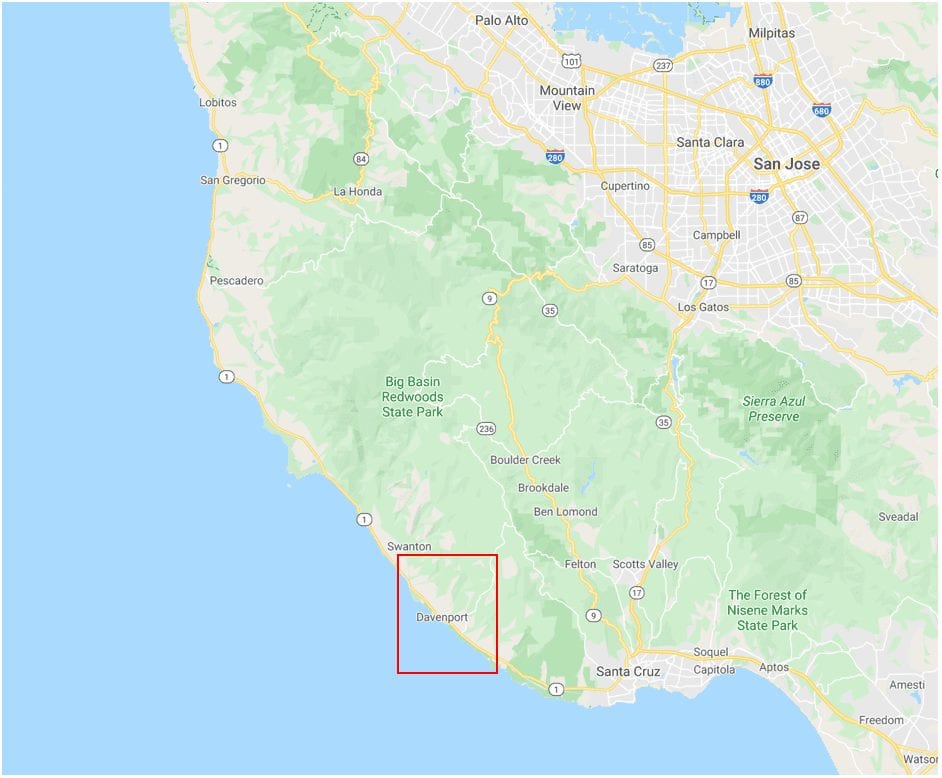

The Swanton Pacific Railroad, located in Davenport, California, faces complications due to weather. Due to the proximity of the site to the ocean, the air is humid. The humid air and cooler winter temperatures in Davenport create a good environment for rust to form. This rust can lead to costly repairs for the railroad when it forms on the locomotives and tools. The cooler temperatures also create less than ideal working conditions due to the outdated heating solutions within the spaces.

Graphical location of Swanton Pacific Railroad.

Design Challenges

- Cold humid climate:

- 37°F in winter with 80-100% relative humidity.

- High infiltration rates within buildings:

- Well above a conservative 0.3 cfm/ft^2 due to age of buildings.

- Outdated electrical system:

- Capacity of about 100 Amps total for the 3 buildings.

- Historical building retrofit and renovation:

- Machine Shop used to be an old Boy Scout kitchen.

Site Visit

February 8th 2020,

We drove up to Davenport to meet the volunteers working there and get to get a better idea of the buildings we were working with. From the moment we arrived we could sense the passion these volunteers had for the site and for keeping Al’s legacy alive.

During the visit we walked through all the buildings noting areas that can be renovated to help decrease the infiltration rate. We also performed in-person building takeoffs where we found the ceiling heights, number of doors and windows, and building orientation. These takeoffs were necessary to accurately perform load calculations for the buildings.

Talking with all the volunteers and hearing their stories gave us a perspective on the importance of this place and further motivated us to find a solution to protect these historic trains for years to come.

Currently, there are standing propane heaters used within the three buildings to supplement the lack of mechanical heating solutions. The Roundhouse also has a small wood fire stove for heating.

Above is on the back side of the railroad. When the railroad opens to the public this is were they host events.

Shown above is the backside of the machine shop.

Load Calculations

Load calculations were done using load calculation software with information based on rough, conservative measurements and impressions from our site visit. We assumed with renovations the building should be sealed to 0.3 cfm/ft^2, still a very high infiltration rate because the buildings are much older. Using weather data stored in the software for Davenport, CA and the building area/ceiling heights, an estimated heating and cooling load was determined for buildings. This load was used when selecting the tonnage for the system component selection.

Machine Shop: Heating Load of 38,000 Btu/hr.

Round House: Heating Load of 64,000 Btu/hr.

This project is sponsored by the Swanton Pacific Railroad.

Existing Conditions

Pictured above is the gathering table with a wood fire stove on the left. This wood fire stove is the only source of heating for the round house.

Above is the inside of the Car Shop. This building is the newest of the three and has a built in crane.

As a result of the property’s age, absence of heating equipment, and lack of renovations the indoor environment is cold and wet. The location provides challenges for these conditions because the cold temperature and high humidity account for rust on the locomotives and equipment as well as issues with comfort for the volunteers. Each building has a high infiltration rate, little to no insulation, and a collection of heavy metal machinery that absorbs heat.

Pictures

Albert B. Smith next to one of his 1915 Panama-Pacific steam locomotive.

1915 Panama-Pacific steam locomotive on a railway turn table.

Infiltration Solution

Interior image of the Round House with locomotive.

Interior of the machine shop. The propane heater is visible on the left.

All three of the buildings we looked at had significant infiltration issues however only the Round House and Machine Shop needed an emphasis on reducing them. These infiltration issues were present through cracks in the old seals on the windows, between doors and door frames, the exhaust and smoke stacks, the gap between train rails and garage doors, and general cracks in the building from lack of renovations over the years.

For the Round House there were many improvements that would help such as replacing all the windows with gas filled double pane windows, replacing and reframing all the doors to prevent gaps between door and frame, adding foam underneath track doors, sealing up exhaust stacks when not in use, and sealing off the plenum from the space below with a rockwool insulation.

For the Machine Shop there were many similar solutions however the cost would be significantly less to fix up compared to the Round House. Again replacing the windows with a gas filled double pane window, replacing and redoing framing around doors, remove or seal up kitchen exhaust, apply a brush seal under sliding doors, and place waterproof foam in the train rails to provide a seal when the tracks are not in use.

Round House

System Specifications

- 6-ton split system:

- Air Handler Unit.

- Condenser refrigerant reheat coil

- Electric reheat coil.

- Condenser split system heat pump.

- With a digital scroll compressor.

- R410A as refrigerant.

- Air Handler Unit.

A photo of the front of the round house showing the connection to the train turntable.

The system operates by mixing outside with inside air and cooling it as it passes over the evaporator, which causes the water vapor in the moist air to condense. The system uses a modulating hot gas reheat coil to route off super heated vapor from the compressor to economically reheat the dried air. If the air needs further heating for comfort it passes over an electric resistance heater to raise the air temperature to the desired set point. The controls system can be set to operate only monitoring humidity levels during off hours and can be set to monitor temperature and humidity during working hours.

Machine Shop

System Specifications

- 4-ton split system:

- Air Handler Unit.

- Condenser refrigerant reheat coil

- Electric reheat coil.

- Condenser split system heat pump.

- With a digital scroll compressor.

- R410A as refrigerant.

- Air Handler Unit.

Exterior picture taken demonstrating the current conditions of the machine shop. Within the machine shop contains many tools along with lathes, mills, drill presses, and other various equipment used to maintain the locomotives.

The HVAC system operates in the exact same manner as the one previously described above for the Round House. Please see Round House for detailed HVAC operation description.

Car Shop

The car shop solution is not concerned with the humidity control of the building so our proposals pertain to heating the building to comfortable working conditions. Our recommended solution is a portable, forced air propane heater capable of heating the entire space within 2 hours. The unit is portable and easily adjustable between the high and low settings and can even be switched off once the space is heated to desired conditions. Another viable solution are wall mounted infrared heaters that provide spot heating for 160 square feet. Finally, sticking with the standing propane heaters is a satisfactory solution, but more heaters are necessary as they are not efficiently sized for the amount of heating they provide.

Exterior picture taken of the Car Shop on the right connected to the Car Barn on the left. The car shop contains a crane for heavier assemblies and the car barn stores the passenger cars.