Our Team

We are the Underdogs, a group of Mechanical Engineering students

Parker Johnson

Design/Manufacturing

I am a fifth year engineering student with a passion for manufacturing. I don’t have any dogs, but my cats have kept my lap warm these past few quarters as I’ve worked on Aspen’s cart. I had a great time working on this project, improving my current skills in fabrication, and gaining new ones.

Jack Montgomery

Design/CAD

I am a fifth year student currently working from my family home in Newcastle, California. It has been a great inspiration to be back home with my four dogs running around me as I work. I hope to help Aspen so she can be just as energetic!

Katherine Thomas

Design/Analysis

I am fifth year student originally from Dallas, Texas and I have a passion for helping others and our environment. I have a rescue dog named Coco that I adopted during my sophomore year who has given me motivation through my degree and this project. I hope to one day work in the clean energy field.

Acknowledgements

We would like to thank Robin Swanson and Audrey Beil for approaching us with such an interesting project. It was so fun getting to know and help Aspen!

Problem Statement

A three-legged dog who just wants to play...

Aspen was hit by a car, and six weeks later surgery was performed on her rear left leg in July 2019. Aspen is having a difficult time adjusting to the three-legged lifestyle as she is energetic and playful. Her missing limb is preventing her from playing for extended periods of time. Aspen’s owners want her to be able go on walks around the neighborhood and hikes on some nearby trails. What makes Aspen’s amputation unique from most is that she was amputated just below her hip. She has no remaining portion of her leg which makes prosthetics complicated. We were tasked with creating a solution for Aspen.

Requirements

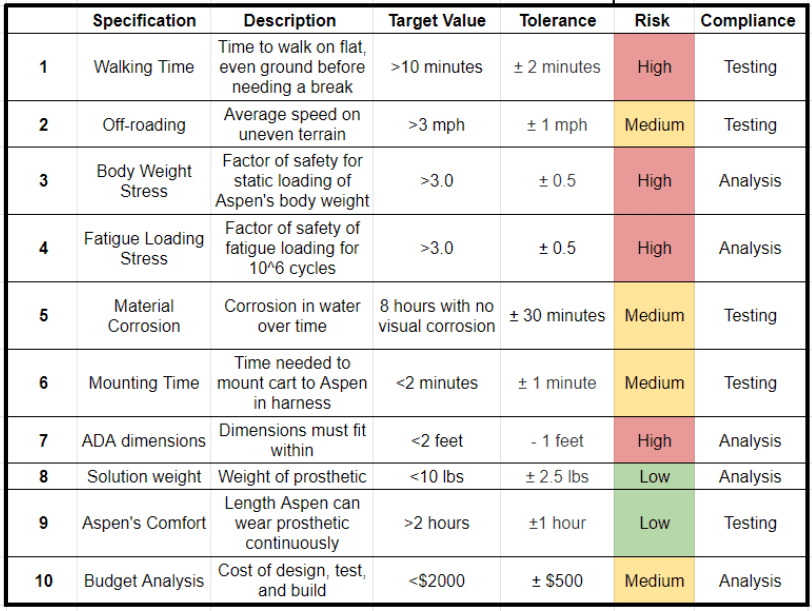

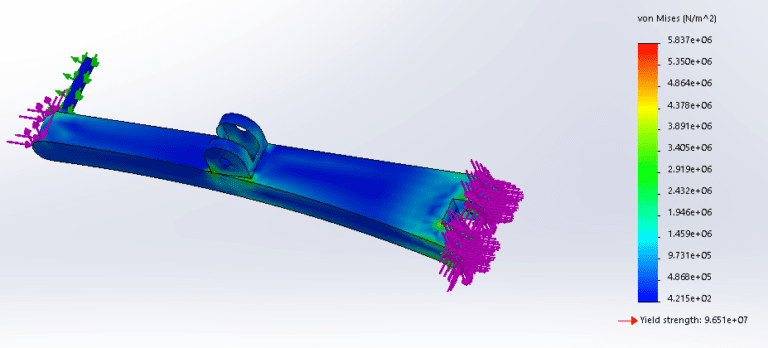

- Factor of safety of 3 against fatigue and static stresses

- Average uneven-terrain speed of 3 miles per hour (or greater)

- All parts of solution are corrosion resistant

- Weighs less than 10 pounds

- Conforms to ADA requirements

- Maximum budget of $2000 for design, testing, and manufacturing

- Allows for normal walking speed over typical terrain (sidewalks, well-manicured trails)

Engineering Specifications

Prototyping & Iteration

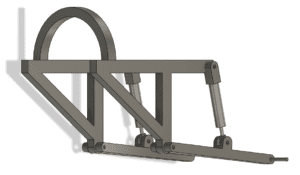

Many different concepts were brainstormed, from actual prosthetics to wheel like supports. After building concept models, a cart design was settled on. The first concept model can be seen below.

Version 1.

- Single large back loop

- Square aluminum stock

- Larger cross section of materials

Version 2.

- Smaller dual back loops

- Mix of rectangular/circular aluminum stock and aluminum plates

- Increased thickness of bracket

Aluminum stock was changed from solely thick rectangular to a mix of aluminum bars and circular tubing

- The stresses were concentrated around the brackets so we increased the strength of the brackets while decreasing the strength of the frame to decrease the solution weight while keeping the same relative factor of safety

Other design choices to note:

- The rear hip support wasn’t modeled in version 1 because originally we were just going to have a sling

- Foam tape was added to contact points between cart and Aspen

Manufacturing

- Manufacturing was largely completed by Parker, at his workplace’s shop

- TIG welding was performed by professional welder

- Rear support was 3D printed

Testing & Calibration

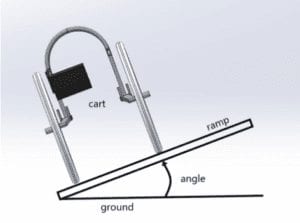

Tipping Test

The Tipping test was to determine what the safe elevation grades of operation were for this cart. We completed this test at an extreme condition (all of Aspens front weight on one side) to ensure that our measurement would encompass all foreseeable uses. Due to the range of locations of the front support and the method of measuring the angle, we decided to run an uncertainty analysis which can be seen below.

Corrosion Test

The Corrosion Test served to prove that the cart would last in wet conditions. Since Aspen lives in the Bay Area, it is likely that the the cart will be exposed to rain and mist. To ensure that the cart would suffer no damage from this, we observed the aluminum stock’s deterioration when submerged in a saline solution. We found no signs of corrosion.

Stress Analysis

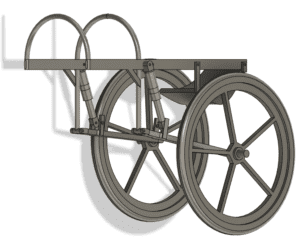

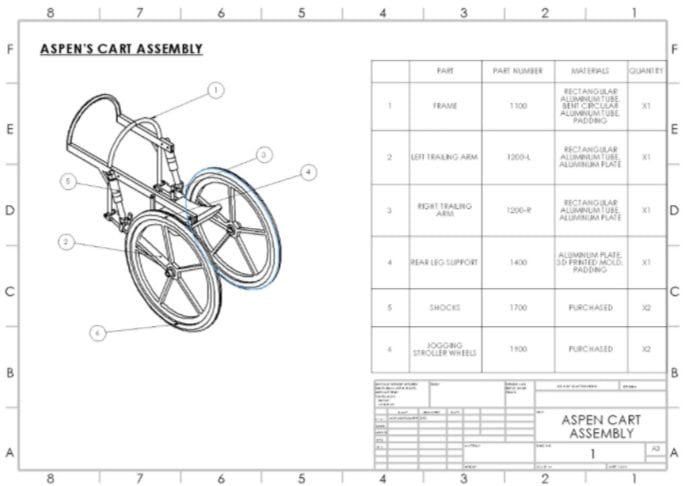

Final Design

Specifications

Weight: 15 lbs

Size: 24″ x 20″ x 10″

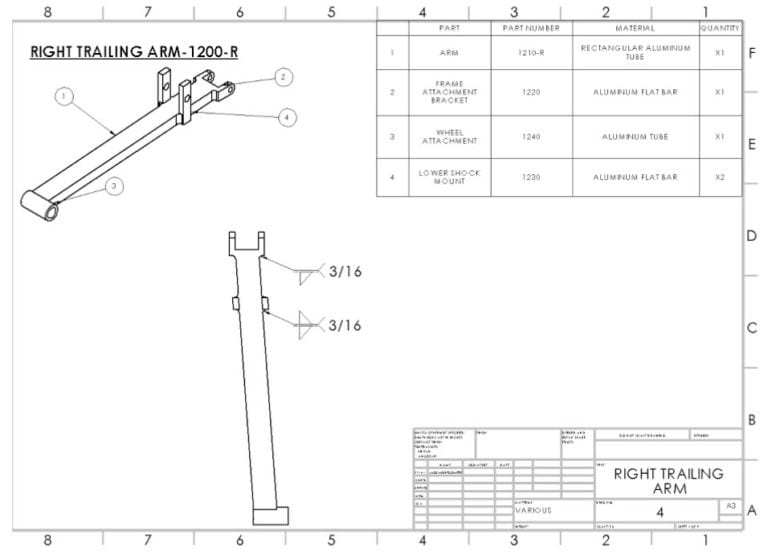

Custom Components

- 3-D printed rear leg support (with dryfast foam)

- Trailing arms (TIG-welded Aluminum rectangular tubing & flat bar)

- Frame (TIG-welded Aluminum rectangular & circular tubing)

Stock Components

- Jogging stroller wheels

- Bicycle air shocks

- Ray Allen Icon Air dog harnesss

Drawings

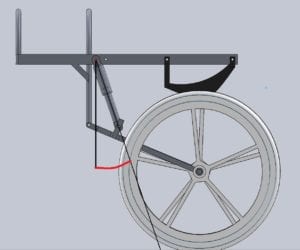

Adjustability

Short travel position

- 10.8° to vertical

- utilizes right hole of top bracket

- 5.242:1 ratio of vertical to horizontal force

- More resistance to vertical shock (better on uneven terrain, i.e hiking trails)

Long travel position

- 18.8° to vertical

- utilizes left hole of top bracket

- 2.937:1 ratio of vertical to horizontal force

- Less resistance to vertical shock (better on even terrain, i.e sidewalks)

Conclusion

Improvements to be made

- The design did not fit Aspen as perfectly as we hoped. We incorporated adjustments for fitment, but not quite enough. The cart could be modified to be highly adjustable.

- The wheels could be more optimized to reduce weight and friction.

References

Nakano, Kahoru Nakano, and 中野 かほる. “JP2003009704A – Walk-Assisting Tool for Pet.” Google Patents, Google, 14 Jan. 2003, patents.google.com/patent/JP2003009704A/en?q=leg&oq=dog%2Bpet%2Bprosthetic%

Bleg.Barr, A. R. S., et al. “Clinical Hip Dysplasia in Growing Dogs: the Long-Term Results of Conservative Management.” Journal of Small Animal Practice, vol. 28, no. 4, 1987, pp. 243–252., doi:10.1111/j.1748-5827.1987.tb03879.x.

Bergmann, G., et al. “A Comparison of Hip Joint Forces in Sheep, Dog and Man.” Journal of Biomechanics, vol. 17, no. 12, 1984, pp. 907–921., doi:10.1016/0021-9290(84)90004-6.

“Bionic Pets.” Bionic Pets, 2020, bionicpets.org/.

“Creating Prosthetic Leg for Tripod Dog.” Health Sciences, University of Delaware, 8 Mar. 2017, www.chs.udel.edu/creating-prosthetic-leg-for-tripod-dog/.

Crowninshield, R. D. “Use of Optimization Techniques to Predict Muscle Forces.” Journal of Biomechanical Engineering, vol. 100, no. 2, 1978, pp. 88–92., doi:10.1115/1.3426197.

“Dog Braces & Prosthetics for Your Pets.” OrthoPets, orthopets.com/.

“Eddie’s Wheels for Pets – The Pet Mobility Experts.” Eddie’s Wheels for Pets – The Pet Mobility Experts, eddieswheels.com/.

Eng, Roy, and Michael Mcguire. “US7549398B2 – Adjustable Wheelchair for Pets.” Google Patents, Google, 18 Oct. 2007, patents.google.com/patent/US7549398B2/en?q=leg&oq=dog%2Bpet%2Bprosthetic%2Bleg.

Goldner, Birte, et al. “Kinematic Adaptions to Induced Short-Term Pelvic Limb Lameness in Trotting Dogs.” BMC Veterinary Research, vol. 14, no. 1, 2018, doi:10.1186/s12917-018-1484-2.

Lee, D. V., and A. A. Biewener. “BigDog-Inspired Studies in the Locomotion of Goats and Dogs.” Integrative and Comparative Biology, vol. 51, no. 1, 2011, pp. 190–202., doi:10.1093/icb/icr061.

Luethje, Thomas. “DE19925629A1 – Wheel-Chair for Dogs Consists of Frame, Side Guide Struts, Suspension, Stomach Sleeve, Straps, Movable Strips, and Bracket.” Google Patents, Google, 7 Dec. 2000, patents.google.com/patent/DE19925629A1/en?q=leg&oq=dog%2Bpet%2Bprosthetic%2Bleg.

“Meet Derby the Dog.” 3D Systems, www.3dsystems.com/customer-stories/meet-derby-dog

Newby, Sylvan, and Dean Pullen. “US9962249B2 – Mobility Aid for Quadrupeds.” Google Patents, Google, 8 May 2018,

patents.google.com/patent/US9962249B2/en?q=leg&oq=dog%2Bpet%2Bprosthetic%2Bleg.

“The Original Dog Wheelchair – Made in USA.” K9 Carts, 15 Jan. 2020, k9carts.com/.

Parkes, Lincoln J. “Prosthetic Cart for Animals.” Google Patents, Google , 24 Apr. 1984, patents.google.com/patent/CA1166095A/en?q=dog&q=pet&q=prosthetic&q=leg&oq=dog+pet+prosthetic+leg.

Parkes, Lincoln J. “US6820572B1 – Mobile Prosthetic Apparatus for Disabled Four-Legged Animals.” Google Patents, Google, 23 Nov. 2004, patents.google.com/patent/US6820572B1/en?q=leg&oq=dog%2Bpet%2Bprosthetic%2Bleg.

Usherwood, J. R., et al. “Mechanics of Dog Walking Compared with a Passive, Stiff-Limbed, 4-Bar Linkage Model, and Their Collisional Implications.” Journal of Experimental Biology, vol. 210, no. 3, 2007, pp. 533–540., doi:10.1242/jeb.02647.

エング ロイ , et al. “JP5385584B2 – Pet Adjustable Wheelchair.” Google Patents, Google, 18 Oct. 2007, patents.google.com/patent/JP5385584B2/en?q=cart&oq=dog%2Bwheelchair%2Bcart.