Our Team

Meet each of the team members who designed a prosthetic foot with the goal to assist a below the knee amputee in the act of surfing.

Alec Goodman

CAD/Builder

I was responsible for the creation of CAD parts in Solidworks as well as finding places to outsource more complex parts. I enjoy riding dirt bikes and going camping with my family. Working on this project was a fun experience for me. I had a great team and I thought the goal for our project was something that would help a lot of people.

Kyler Peterson

Communicator/Treasurer

I was the single point of contact with our sponsor from QL+, who focused on coordinating with the team to meet deadlines. I have an interest in engineering design, where the satisfaction of seeing a working prototype has only enhanced this interest. I also enjoy spending time at the beach, playing frisbee, and making a prosthetic which will have a positive impact on someone’s life.

Aris Recidoro

Coordinator

I was responsible for making a schedule throughout the year and making sure we as a team met the deadlines. I like Piña colada and getting caught in the rain. I am also a diehard 49ers fan and have rewatched the show Community three times. I like to tinker with things so working on this project was a lot of fun and it was great experiencing being in charge of the project direction.

Acknowledgements

This project is a continuation of a Surf Leg V1 created in a previous Cal Poly senior project. This was initially sponsored and funded by QL+ until they pulled out near the end due to unforeseen circumstances. The project is a project for Operation Surf, a non-profit organization started by Van and Amanda Curaza whose mission is to help veterans rehabilitate from mental and physical disabilities through the healing power of the ocean by teaching them how to surf. Additionally, one of the members of the last senior project, Samantha Campbell, was a consultant for our team throughout the year.

Project's Videos

Surf Leg Digital Poster

Design

Our prosthetic was designed to be used for below the knee amputees in the ocean with a variety of different user builds. It needed to be adaptable with multiple weights and multiple heights of various users. It also needed to be lighter than previous designs.

Design Requirements

- Designed with a max weight of 300 pounds

- Lighter than 10 pounds

- Needs to be Salt water resistant

- Needs to be comfortable for long periods of time

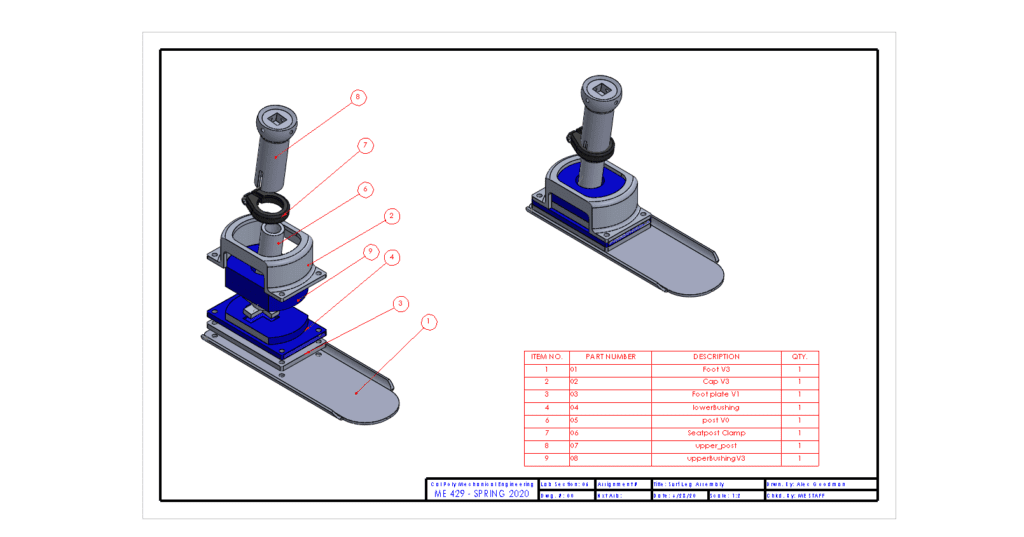

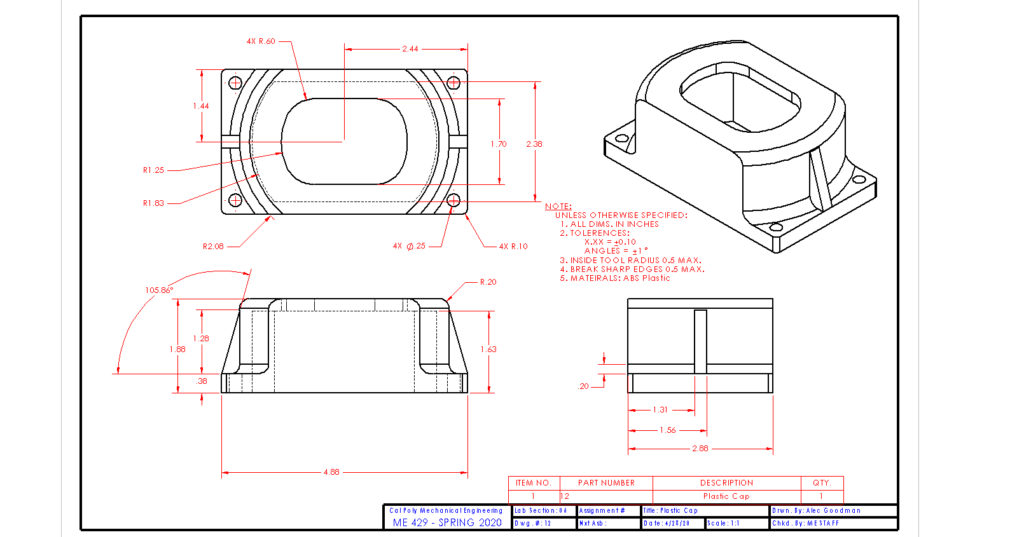

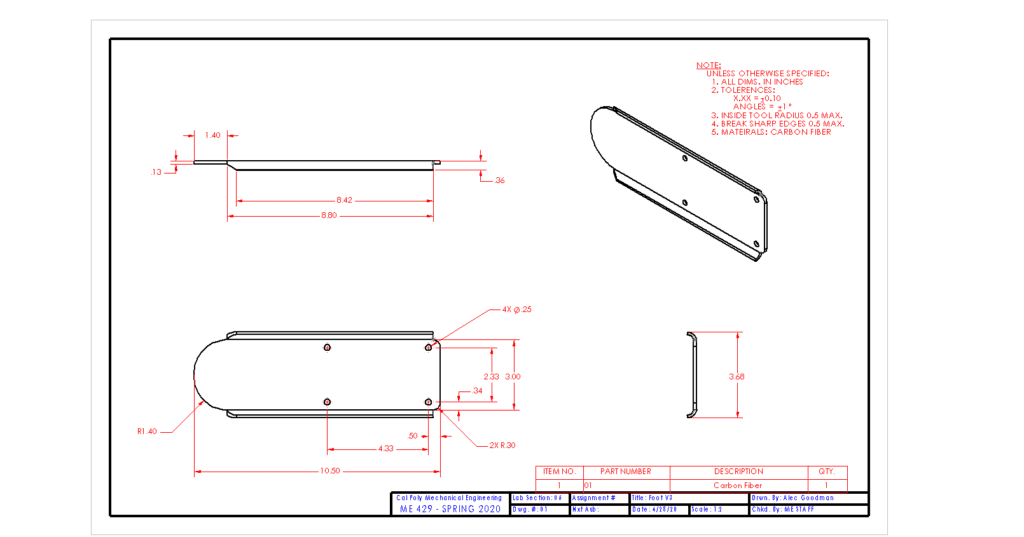

CAD Modeling

Each of our parts were designed using the Solid Works CAD program. We used Surf leg V1 as a base for our designs and then proceed to modify them to be lighter.

Two of our more complex designs are shown below. The ribs on the second picture allowed for more support front to back while the edges on the foot allowed for support on the side to side roll.

Material Choices

After researching material and analyzing their properties we chose to make our foot out of Four different materials. We chose Carbon Fiber, ABS plastic, Aluminum, and PolyTek rubber. The reasons are explained below.

Carbon Fiber – This material was chosen due to its strength and limited flexibility. It seemed to be a commonly used material for prosthetics which is why we looked into it.

ABS Plastic – This material was chosen due to its durability, Strength, and weight. It was much lighter than the aluminum equivalent and had enough strength to serve our purposes.

Aluminum – This material was chosen for its high strength and low weight. It was used in key weight bearing areas that we couldn’t use the ABS.

PolyTek Rubber – This rubber had various resistances to choose from which allowed us to have lighter and heavier weights depending on the user. It was also pourable which allowed us to mix them for more variety.

This project was sponsored by Cal Poly & QL+ based upon the needs of Van Curaza and Operation Surf

Introduction

Problem Definition

The team members of this project are Alec Goodman, Aris Recidoro, and Kyler Peterson and the purpose of our senior project was to improve Surf LEG V1, the previous senior project’s product. We listened to the feedback that Van Curaza and QL+ had from the last version and decided that our main emphasis was to decrease the weight of the leg and increase its mobility and all around functionality.

Testing

Movement Test

The most important tests we conducted were weight and movement tests in order to see how the legs mobility would perform under the stress of a prospective user.

Forces ranging all the way up to 60 lbs were applied in all directions to see how the leg would perform and the angle achieved. The leg was able to hold up to the forces and the range of motion achieved hit our specifications.

Durability Test

We tested the legs durability to outside forces and extended use.

The leg was put through squat motions 300 times with an applied force of 50 lbs to see if any wear occurred. Some cutting was found in the rubber so the cross section was rounded out to reduce the effects. Other than that, the leg held up and no other fatigue was found.

Through these tests and multiple other minor tests, we found that he leg had the proper range of mobility needed for surfing and could withstand outside forces from all directions.

Results

After completion of the surf leg prosthetic prototype, all tests which were conducted met and exceeded the desired specifications. The weight test with a goal of under 10 lbs was exceeded by a final design weight of 2 lbs.

Considering the durability and movement tests, the prototype met all specifications with minimal wear on the rubber ankle component. We proceeded with purchasing more liquid rubber to provide our sponsor with additional rubber ankle components. This is incase the fatigue on the rubber after many uses begins to compromise the functionality.

Manufacturing

3D-Printed Parts

Due to COVID-19 restrictions, a number of our parts were manufactured via 3D-printing. This included the following:

Carbon Fiber/ABS Foot

ABS Foot Plate

ABS Ankle Cap

PLA Rubber Ankle Molds

Liquid Rubber Parts

The mobility of our foot was provided by a liquid rubber gelatin of different strengths that was set in the 3D-printed molds above. This required combining two solutions together, provided by PolyTek, which after mixing would begin to harden within five minutes.

Aluminum Parts

The two knee components, as well as the post clamp with allows for height adjustability, was all purchased in aluminum. The bottom knee post with an outer diameter of 1.00″ fits inside the top knee post with an inner diameter of 1.25″. An aluminum cross was welded to the bottom of the bottom knee post as shown below.

Bottom Knee Post

Top Knee Post

Post Clamp

Future Recommendations

The final step of our design process, which will be up to our customer due to COVID-19 restrictions, is to successfully use the foot with an adaptive athlete. As all possible tests which could be conducted with the team were implemented and successful, the only thing left to do is present this design to a below-the-knee amputee and grant them the thrill of surfing.

We also would have liked to make the foot out of pure carbon and layed it up ourselves as this would have been a great learning experience as well as provided the foot with increased strength.

As the foot itself is completed, there is nothing left for the sponsor to do except for add a rubber covering to the bottom of the foot to protect the surfboard from the scratching of the carbon fiber foot.