Our Team

Jose Chavez

I am a 5th year Mechanical Engineering student. I enjoy spending time with friends, fishing, and watching movies.

Brennen Irey

I am a 4th year Mechanical Engineering student. I enjoy tinkering, 3D printing, and working on anything with an engine in it.

Jack Cerron

I am 3rd year transfer ME student with a General Concentration. I enjoy working on challenging project and getting my hands dirty.

James Popolow

I am a 5th year Mech E. student with a Concentration in Mechatronics and a Minor in CS. I enjoy reading, tinkering, and spending time with friends

Our Sponsor

Dr. Lauren Cooper is a Professor in the Mechanical Engineering department at Cal Poly. She worked in the renewable energy industry before returning to academia as a professor. Her Ph.D. in Mechanical Engineering with a specialty in Engineering Education and her ongoing research into improving engineering education are testament to her passion as an educator.

Project Videos

Project OVerview

Guided Activity Demonstration

Project Information

Problem Statement

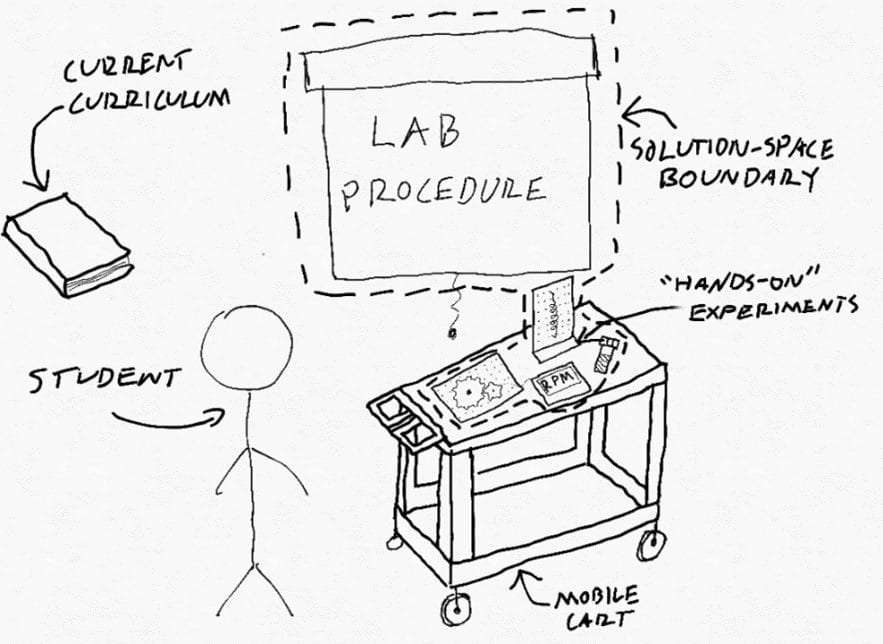

Professor Cooper, and other ME 329 professors, need a way to teach students power train design concepts in an interactive, hands-on way that shows the application of the concepts to real-world systems. These laboratory activities should be easy to use, low in cost, durable, and provide students with an exploratory and learning experience using quality parts that will focus on gears, shafts, and bearings. They should produce measurable results in response to changing parameters. It should also help them through a design activity that will model a real-world scenario.

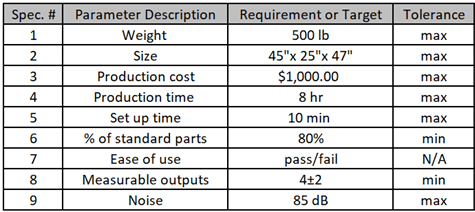

Project Specifications

Customer needs:

- • Safe and easy to use for students

- • Interactive with measurable outputs

- • Applicable to the real world

Customer wants:

- • Manufacturable by student shop techs on site

- • Composed of off-the-shelf, industrial level parts

- • Robust and maintainable

Project Scope

We made the following three decisions to define the focus of our project:

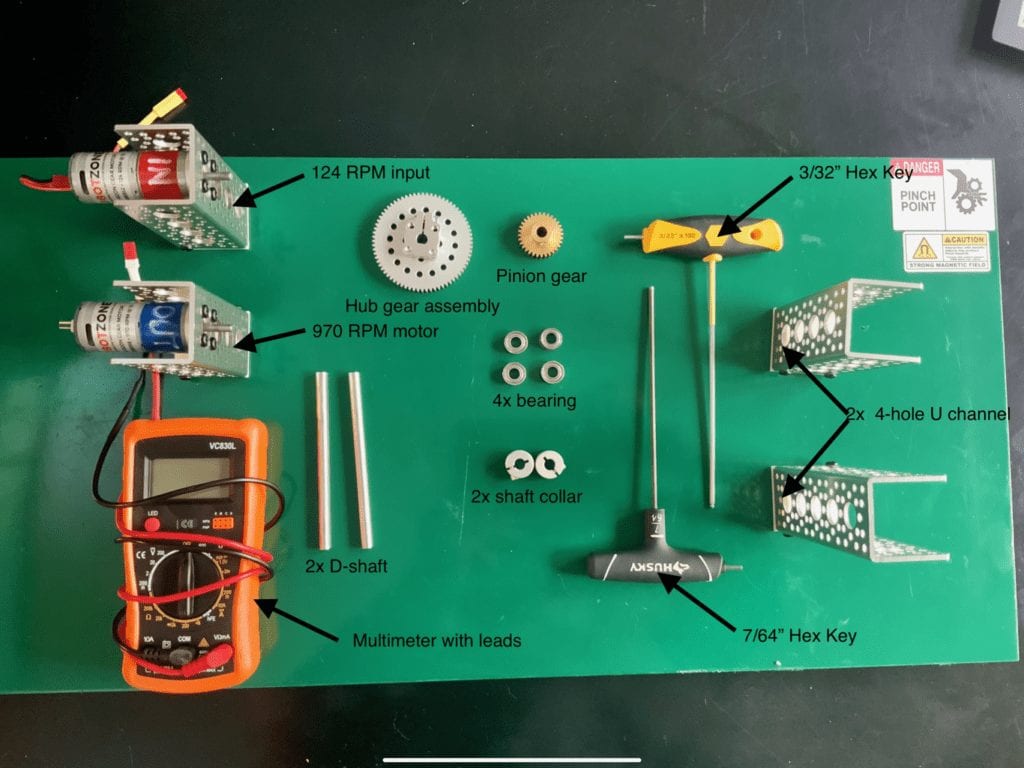

- 1. We will focus on concepts related to gears, gear trains, and power transmission systems.

- 2. The best solution would be a three-activity series consisting of an Exploration Activity, a Demonstration Activity, and a Design Challenge, but we will focus on the Exploration and Design Activities.

- 3. We will develop learning objectives and lesson plans to accompany the physical apparatuses for each activity

Research

We gained several key insights from interviewing Professor Cooper at the beginning of the project:

• Students sometimes have difficulty connecting lab activities with real world applications

• Most existing lab activities are either not hands-on, feel like a toy, or are too abstracted from industry application

• An activity related to wind turbines might be great for both Dr. Cooper and students

• The best topics to cover would be gears, gear trains, and/or fasteners

• Quality of parts are not as important as the context of the lab experiment

We also interviewed several current or former ME 329 professors including Professor Schuster, Professor Mello, and Department Chair Widmann. We found that, in general, they agreed on several key things. The solution should be:

• Safe

• Easy for faculty to use

• Easy for students to use

• Easy for the department to acquire and maintain

• Hands-on and interactive

• As high quality as possible

As users of our final product, we also surveyed ME 329 students. We received responses from 50 former students, 35 former students, and 3 future students.

We asked them:

What type of lab activity would be most useful to have more of in classes like ME 329?

Top answer: Interacting with (potentially scale) models of real systems, changing parameters and measuring effects.

Which of the following would be the most interesting/useful to you as the topic of a lab activity?

Top answer: Gear trains, shafts, and bearings

In a few words, what is it about the types of activities you selected that makes them useful?

The words appearing in the answers appear in the word cloud to the right. More common words appear larger

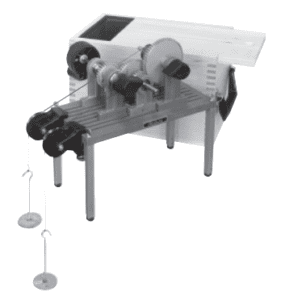

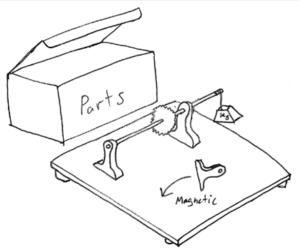

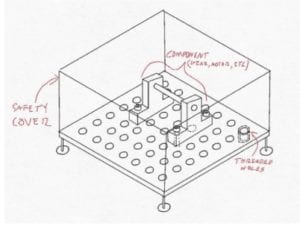

We researched various existing products in order to gain insight and inspiration for our design. Two specific products, PIC Design’s educational kit and Stokys kits, heavily influenced our design process. PIC Design’s educational kits use a modular system consisting of different mechanical components that can be rearranged and positioned using a system of rails. Our decision to use a magnetic positioning system with pillars was greatly influenced by these educational kits. Pictured below is the gear-focused educational kit:

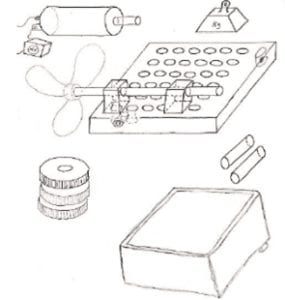

The other product, Stokys kits, provide users with a variety of structural, mechanical, and fastener components . This allows users to create many different configurations from the same base set of components. We liked the customization that Stokys kits allowed and decided to provide a variety of components to our kit to allow for maximum customization by our student users. Pictured below is one of the kits available from Stokys:

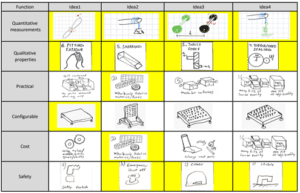

Ideation

1. Create a functional decomposition

2. Ideating on solutions for each function

3. Modelling the best ideas

4. Evaluating through Pugh and weighted decision matrices

5. Selecting the scoring design components and compiling them into the best design

We settled on a two-step solution: Exploration Activity + Design Challenge

Design Verification

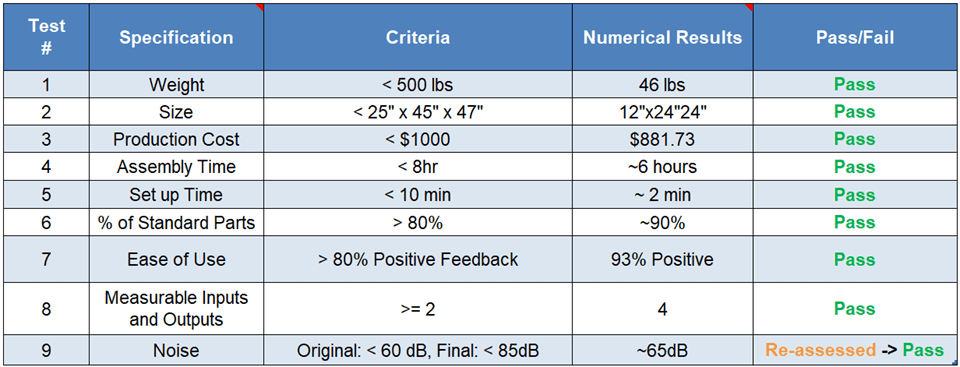

We originally set our noise limit for specification #9 at 60 dB as this was the level at which normal conversation starts to become affected according to our research. However, upon testing our motors, which give off ~65dB at a distance of 1 foot, we noted that the noise levels were not uncomfortable and did not interfere with our conversation. We decided to adjust our noise specification criteria to a max of 85dB which is the OSHA limit for safe exposure over an 8 hour work day without hearing protection.

Acknowledgements

We would like to thank our project advisor, Dr. Peter Schuster, for supporting and guiding us throughout this project. We would also like to thank Meredith Gruben for handling all purchasing of required components and materials. Finally, thank you to the many professors, students, family and friends who provided feedback throughout the project.