Our Team

Rachel Davis

Rachel is a senior Industrial Engineering student. After graduation, Rachel will be working for Cisco as a Business Analyst.

Nicky Rodriguez

Nicky is a senior Industrial Engineering student and is pursuring her masters in Engineering Management. This summer Nicky will be interning at Cisco.

Tatum Shore

Tatum is a senior Industrial Engineering student and is pursuing her masters in Engineering Management. After graduation, Tatum will be working at Deliotte Consulting.

Acknowledgements

Special thanks to:

Dr. Liz Thompson, Senior Project Advisor

Dr. Tali Freed, Senior Project Coordinator

Shilpa Tamma, Project Sponsor

Vineet, Landed Cost Model Subject Matter Expert

Dr. Hill, Model Formulation Subject Matter Expert

Dr. Awwad, Supply Chain Logistics Subject Matter Expert

Our Project's Videos

The following videos should be replaced by embedding the link(s) from your own YouTube video channel. Please DO NOT upload video files directly to WordPress.

Our Project's Digital Poster

Problem Statement

Cisco currently does not have the most optimal network and landed cost for their products, specifically when products travel to multiple warehouses. Therefore, Cisco would like to identify the optimal process to decrease costs and lead time.

Current State:

The current state of Cisco’s supply chain is that products are statically routed through the supply chain going from a contract manufacturer, to an SLC, to the market. This project aims to identify if and when the step of the SLC should by bypassed.

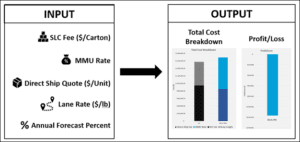

Landed Cost Model

Solution Design:

- Goal is to determine which of the two routes is most optimal for Cisco from a cost perspective

- The landed cost of an item consists of the summation of the costs incurred to get the product to the customer

- For example, product A has a landed cost of $X for the SLC route and a landed cost of $Y for the direct ship route.

- The model then compares $X and $Y and evaluates which option is cheaper, and thus the best route from a cost perspective for Cisco

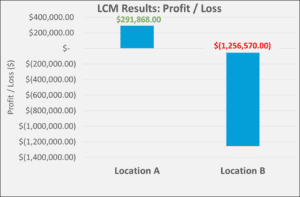

Results:

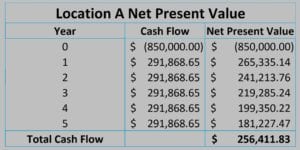

- Location A: Profit of $291,870

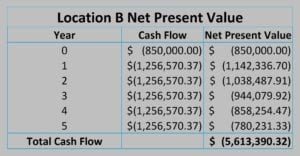

Location B: Loss of $1,256,570.00

Verification and Validation

- User Verification:

Two main goals for both models:

Make the models user-friendly

Meet Cisco’s desires

Verify: Ask the SME to perform functions on dashboard and Power App

Validate: Ask for feedback to ensure models met Cisco’s expectations

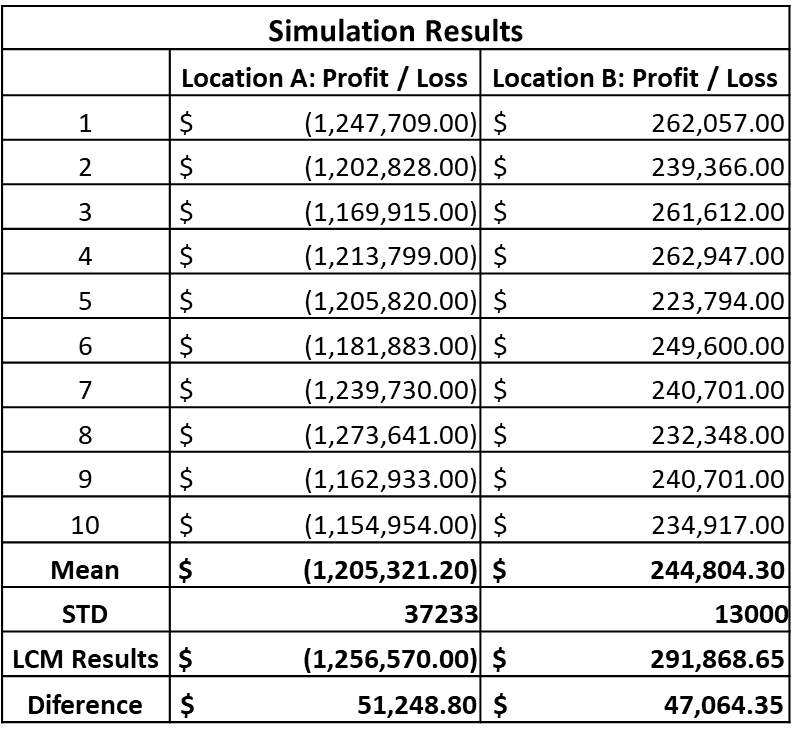

Simulation Validation:

Created for the landed cost model

Used AnyLogic to simulate the process from an order being placed to the final step of being shipped to the market

Implementation and User Guides

- Landed Cost Model:

- Cisco’s goal for the landed cost models is to transfer the two models and expand them to other locations.

- Training guide gives the user instructions of how to recreate the LCM with other locations

- User guide gives the LCM user instructions of how to use the model

- Dynamic Routing Model:

- Training video to recreate Power App

Project Objectives

Task 1: Landed Cost Model

Identify if there is a cost benefit of directly shipping products from specific Contract Manufacturers to the customers. We are focusing on two specific locations.

Task 2: Dynamic Routing Model

Build a model to decide when Cisco should route a product through an SLC and when they should directly ship the product

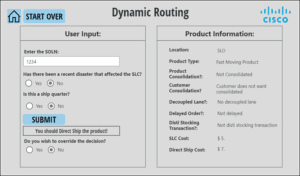

Dynamic Routing

Solution Design:

For the dynamic routing model, the team built this solution by using Microsoft PowerApps:

- Two sections on the dynamic routing screen: the user input and the product information

- User inputs SOLN (order number) and product information section populates

- User identifies if a recent disaster occurred and if it is a ship quarter

- Application calculates the total weight for each factor

- The direct ship total and SLC total is calculated and shows how to route the product

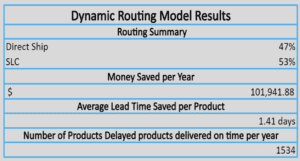

Results:

- Using historical data, the team compiled various key performance indicators:

47% of products would be directly shipped

Cisco would incur a cost savings of approximately $101,941 per year

53% of products would be routed through the SLC

Average lead time saved per product: 1.41 days

Total number of delayed orders that were delivered on time per year: 1534 orders.

Impact Analysis

NPV Calculation Inputs:

- Profit or Loss calculated from LCM

Payback rate of 10%

Total Cost of Implementation: $850,000

Results:

- Location A: Profit of $256,411.83 after 5 years

- The team reccomends to invest in dynamic routing at Location A, as it is a profitable investment

- Location B: Loss of $5,613,390.32 after 5 years

- The team does not reccomend to invest in dynamic routing at Location B, as it produces a loss