Our Team

Meet the team behind the air cannon at the San Luis Obispo Botanical Gardens!

Sydney

Hosokawa

SHE/HER/HERS

Sydney is a fourth year mechanical engineering major with a general concentration from Sacramento, CA. She enjoys her time outdoors, traveling, and spending time with family and friends. After graduating, she will be working in the medical device industry.

Jordan

Nguyen

HE/Him/his

Jordan Nguyen is a fourth year mechanical engineering major with a general concentration from Westminster, CA. After his undergraduate term, he will be hunting for a job in the biomedical industry with the possibility of going back to school sometime in the future to pursue further education.

Jessica

Ouyang

SHE/HER/HERS

Jessica is a fourth mechanical engineering student from Pleasanton, CA. Her hobbies include spending time at beach, traveling around the world, and going to concerts. In the next year, she will be working on getting her master’s degree here at Cal Poly through the Blended Program.

Marina

Smeltzer

SHE/HER/HERS

Marina is a graduate mechanical engineering student from Paso Robles, CA. She enjoys spending time outdoors, especially at the beach and in the pool. She is pursuing a job where she can put her knowledge of mechanical engineering to good use.

Acknowledgements

We would like to thank our SLOBG sponsors, Eve, Anika, and Michael for supporting us throughout this project, along with Steve and Larry, SLOBG volunteers who were crucial in the installation of the air cannon. We would also like to thank the Cal Poly Mustang 60 Machine Shop and the helpful student technicians, along with Eric Pulse for their manufacturing tips and patience throughout the build phase of our project. And lastly, a huge thank you to TnT customs in Paso Robles who did an amazing job painting the air cannon to give it a real aesthetic wow factor and GAR Bennett for donating the 24″ diameter PVC pipe that made our project possible.

Our Project's Videos

To the left is a video about our project and the process it took to get there.

On the right is a video about the SLO Botanical Garden.

Our Project's Digital Poster

Background

what is the need?

The sponsors from SLOBG wanted an interactive physics display to be implemented in their children’s garden to educate children and adult visitors about physics concepts in a welcoming and comfortable atmosphere.

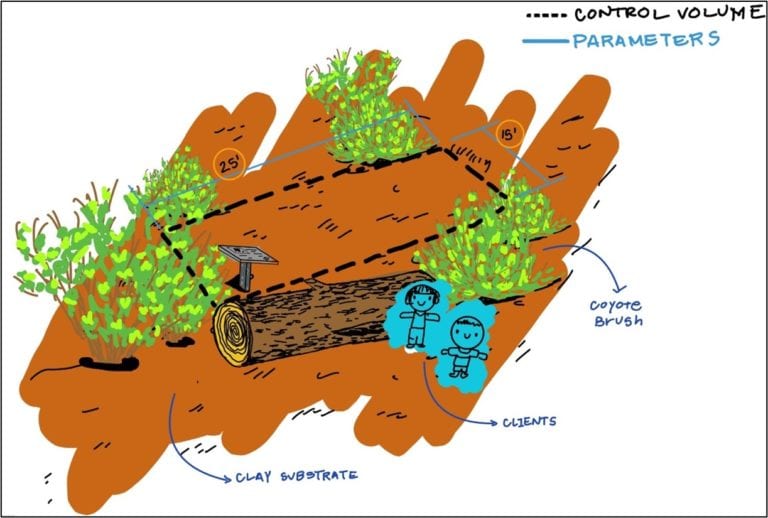

The boundary diagram for the project shows the land that was set aside by SLOBG in the Children’s Sage Meadow. The visitors played a part in the design as their age and physical capabilities had to be considered to create a design that is effective and sustained. A sign explaining the structure and the physics concepts is placed next to the structure in English and Spanish.

Ideation

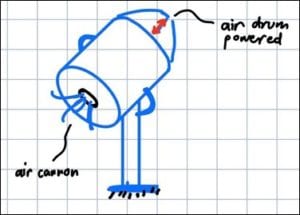

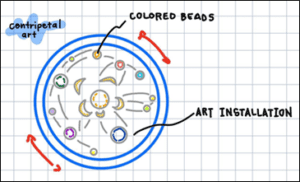

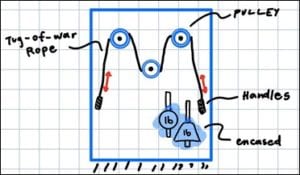

An accumulation of all the brainstorming sessions, initial general research, and constant flow of ideas resulted in concept designs for this project. Starting with a functional decomposition tree and brainstorming, ideation models were created and presented to the sponsors.

A pugh matrix contributed to deciding the top ideas shown in Figure 2, 3, and 4.

Concept Design

Figure 5 displays the original sketch for the log target stand and building blocks that would have been attached to the stand with a cord.

concept sketch

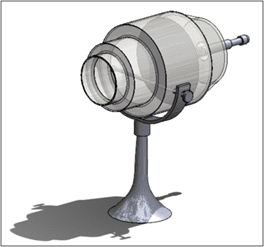

Concept cad model

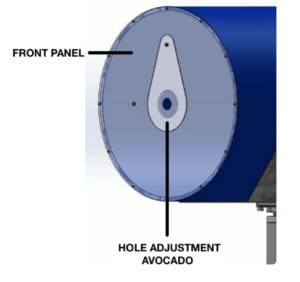

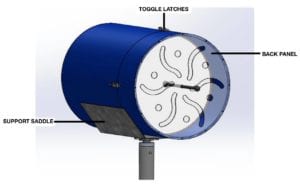

After creating the concept prototype shown in Figure 6, a computer-aided design (CAD) model was employed to show the air cannon in more detail. The CAD model of the air cannon shows the swivel feature that was not in the concept prototype. An isometric view of the air cannon is shown above in Figure 7.

Structural Prototype

This was the final Structural Prototype, which was used to verify that the model could be scaled up in size and that manufacturability was plausible. Preliminary testing showed that the air pressure at the exit hole was significant even at a larger drum size.

Engineering Analysis

Strength analysis

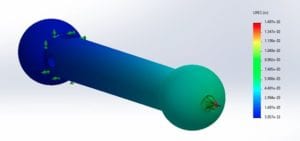

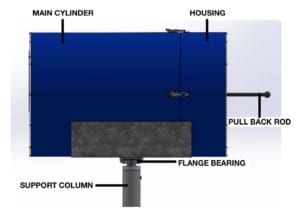

The pull-back rod was originally a plastic 3-D printed part and it was tested using finite element analysis (FEA) to show how structural strong it is. However, even though the final design uses a metal rod which is stronger than plastic.

Structural analysis

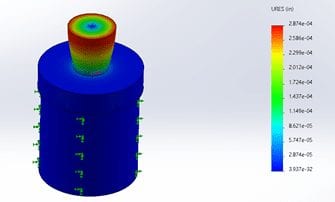

The point of failure is at the bearing pole mount so it was vital that stress analysis was done on it.

Finite element analysis was done on the displacement of the bearing pole mount with a 400 lbf torque applied, showing that the displacement is indiscernible at around 0.0003 inches.

Testing

Accuracy test

The accuracy test’s goal was to determine how far the pull-back rod needed to be pulled in order to produce expected results. From testing, it was found that the pull-back rod produced accurate results when fully pulled back and one inch short of fully pulled back. This test is shown below in Figure 11.

Distance test

The exit air distance the air cannon created was measured by shooting the air cannon at the targets from determined distances. The final distance the larger exit hole was able to knock down the targets before failure was four feet. This test is shown above in Figure 12.

Manufacturing

San Luis Obispo Botanical Garden

The San Luis Obispo Botanical Garden (SLOBG) is a non-profit organization that provides a place for visitors to connect with and explore nature.

Final Part

demonstration

final cad model

Key Findings

After assembly and testing, it was found that the smaller exit hole that we included in the design did not produce a higher exit pressure as expected from Bernoulli’s principle. This was due to the vacuum that was created inside the drum. The diaphragm was unable to spring back as quickly, causing the exit stream to be weak and was not capable of knocking down the targets. The air was also exiting between the seam of the exit hole and the avocado piece, damping the air stream.

Conclusion

A huge motivating factor throughout this engineering design process was the understanding that this product has the power to educate and inspire the next generation in STEM. From the beginning, the goal was to create an interactive physics display that demonstrated the laws of nature, bringing those that visit the garden closer to the great outdoors. The mechanical air cannon the team built demonstrated Bernoulli’s principle in a simple and engaging manner, while utilizing nature as the key component, contributing to the effectiveness of the display. Seeing the project from conception to installation provided insight into the iterative nature of the engineering design process.

Recommendations

The iterative nature of the engineering design process and bringing a concept to life in a relatively short time frame allowed the team to reflect on the aspects that worked and the aspects that could have been improved upon further.

1. Encasing the pull-back rod with a spring to create a higher exit velocity and hopefully achieve farther exit distances for the target stands.

2. Testing on various exit hole diameters and creating a more stable mechanism for varying exit hole sizes.

3. Incorporating a swivel stop on the bearing to prevent the air cannon from rotating 360 degrees.

4. Optimizing the bearing-pole mount to further reduce any stress concentrations and incorporating a press fit into the pole instead of a clearance fit.

5. Testing on clear plastics that can withstand weathering, easily water-jetted, and scratch-resistant.