Concept Prototype

Our concept prototypes for this activity were not very functional, but demonstrated the intention of the design concept.

Learning Objectives

This activity has a number of core learning objectives that students should achieve with anything but the most basic implementation of this activity.

Core Learning Objectives (* = direct from class syllabus):

- • Generate ideas and concepts for mechanical designs*

• Select appropriate machine elements, components, and materials for mechanical systems*

• Analyze and size selected machine components for appropriate strength, stiffness, or fatigue life*

• Apply computer-aided engineering techniques to component and system design*

• Kinematic analysis and design of gear trains*

In addition, there are a number of learning objectives that students will achieve if most or all of the recommended requirements are requested.

Extension Learning Objectives:

- • Predict and measure power losses in drive trains

• Measure efficiency of a mechanical drive train system

• Integration of fluid dynamics with mechanical systems

• Selection of optimal electro-mechanical components

Documentation

Guides students through the lab.

Advises professors on how to implement the lab.

Design Challenge Activity

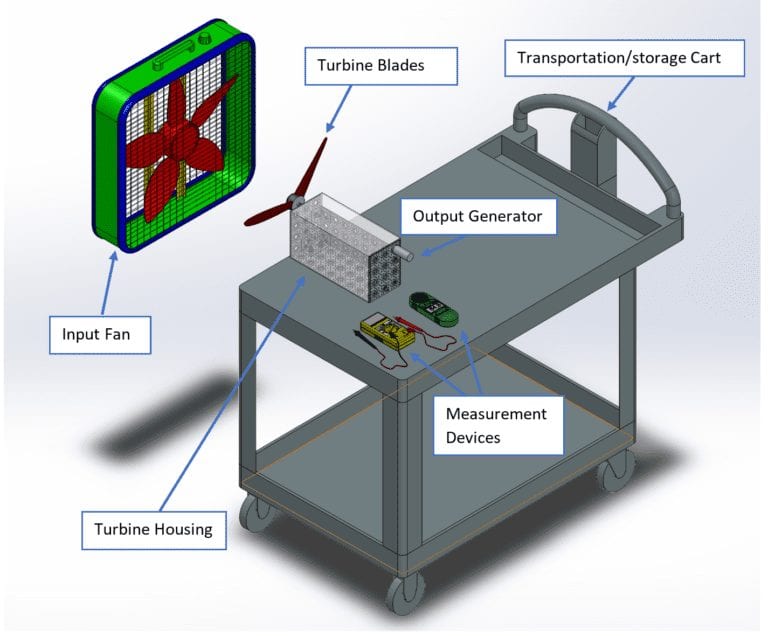

Final Design

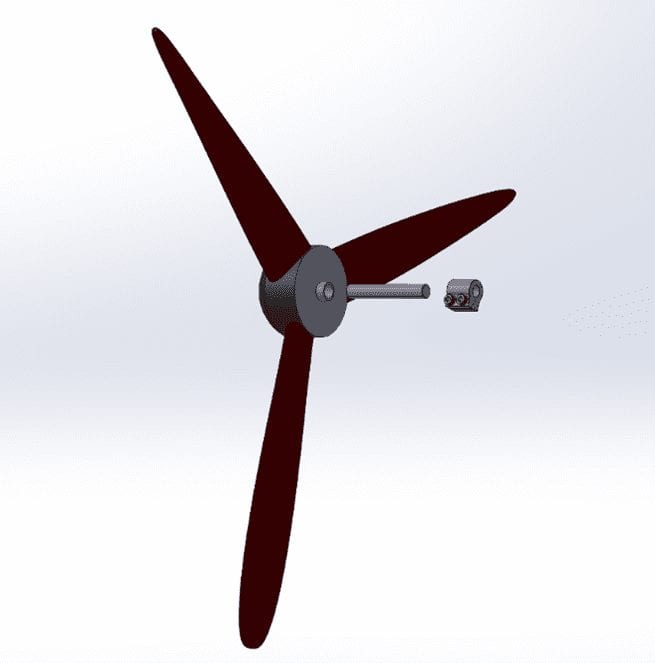

For this activity, groups of students are challenged to design a drive train for a model wind turbine with the goal of maximizing power output.

They will do this over 1-6 weeks before testing their designs to see which groups’ is the best.

Professors can choose to ask for any or all of the following requirements for this project:

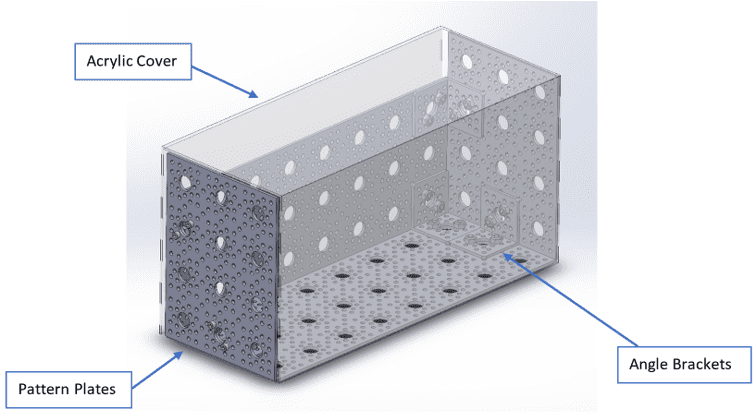

- • Power train must fit within housing

• In-line input and output shafts

• A CAD model of final design

• Force analyses- o FEA of their design

- o Calculation of all forces within their power train

o Identification of point of failure in their design

o Calculation of expected shaft bending

- • Calculation of expected input power

• Calculation of expected power losses, output power, and efficiency

• Design review presentation including all of the preceding items in this list

• Calculation of actual efficiency using expected output power and output power measured during testing

• Post-testing report/presentation explaining suspected reasons for variation between expected and actual results

Drive train components will come primarily from the core components of the exploration activity. However, there are additional options that may add to the learning experience:

- • Advanced components such as chain drives, worm gears, and bevel gears

• 3D printing components not supplied in their kit

• Using a small group budget to purchase components from Servo City

On test day they will be provided with a housing, turbine blades, and a fan. They will implement their design in the housing, attach the blades, and use the fan to simulate wind, measuring output power using a multimeter.

Verification

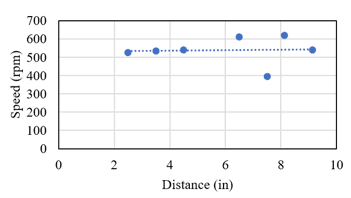

Backwash Test Results

- This test was performed to see the effects of backwash on the wind turbine design.

- Input fan distance was set fixed.

- The distance between fan blades and the housing varied.

- The results in the plot show that the lowest rotational speed is 2% slower than the average speed across all. distances

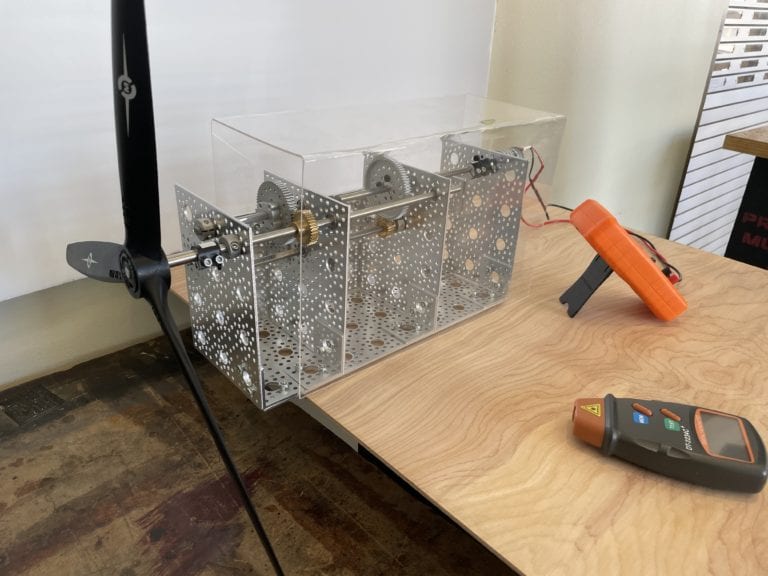

Preliminary Testing

- This preliminary test confirmed that the wind speed had enough power to overcome the frictional forces at the gear train.

- For this test, we used two gears, two 3D printed costumed wind turbine blades, and a DC motor.

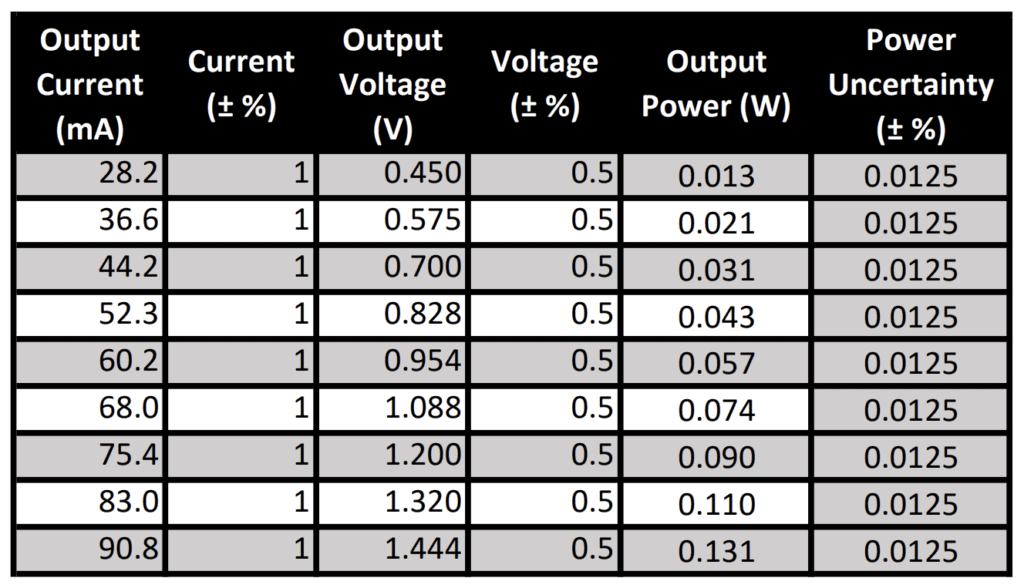

Power Uncertainty Analysis

- The output power uncertainty is ±0.0125%

- The multimeter has a current uncertainty of ±1.0% and voltage uncertainty of ±0.5%

- The output current contributes to most of the power uncertainty

Cost

This activity benefits from re-using many of the components from the Exploration Activity as well as the fact that only a couple need to be provided per class for testing day.