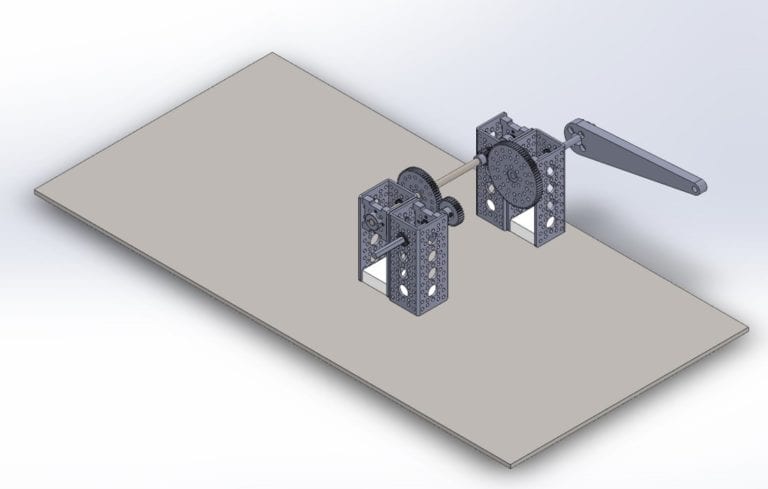

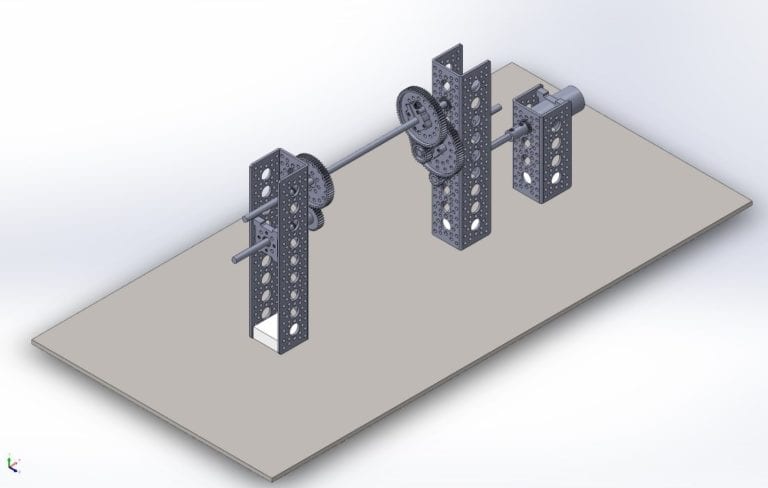

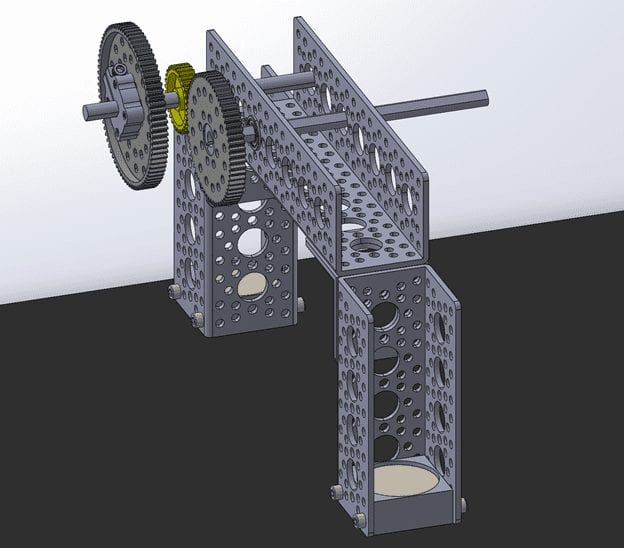

Concept Prototype

Our first concept prototype came from Lego Technics. We liked the idea of being able to build any configuration we wanted with multi-purposeful components.

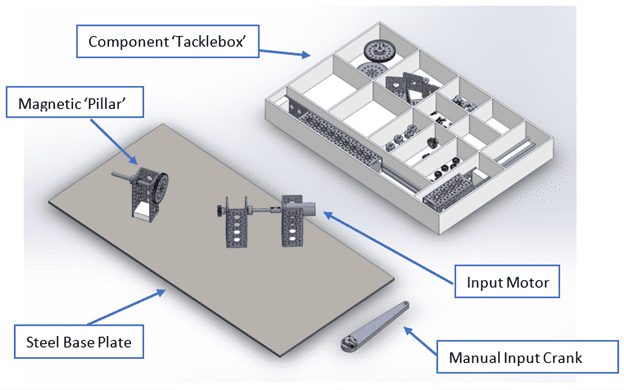

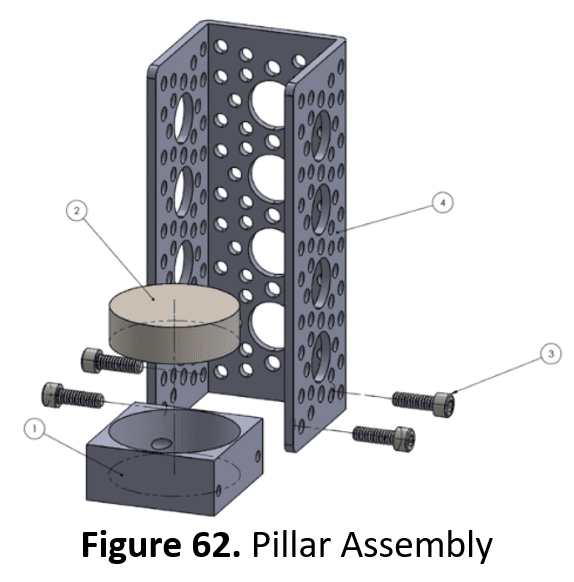

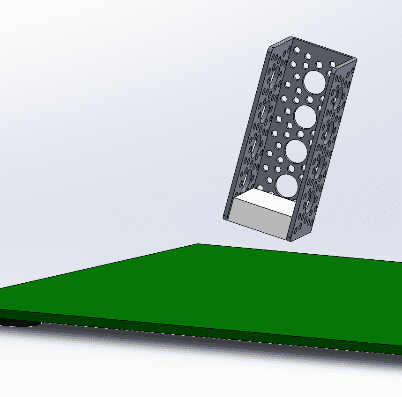

SolidWorks was a great tool used to model the more robust components of our prototype design. The supplier had all major building components already modeled up ready to be downloaded for free.

Learning Objectives

The core learning objectives are:

- • Practical behaviors of gears and gear trains

• Practical experience with spur gears

• Design and behavior of speed increasing and torque increasing systems

• Properties of forces between meshing gears

• Measurement of drive train system properties

Additional learning objectives through careful observation and experimentation with the ‘extended learning’ components include the following:

- • Observe causes and effects of shaft bending

• Observe causes and effects binding of shafts and bearings

• Observe causes and effects of drive train friction

• Practical experience with worm gear systems

• Practical experience with helical gear systems

• Practical experience with bevel gear systems

• Practical experience with chain drive systems

• Practical experience with belt drive systems

Documentation

Guides students through the lab.

Advises professors on how to implement the lab.

Feedback

Exploration Activity

Final Design

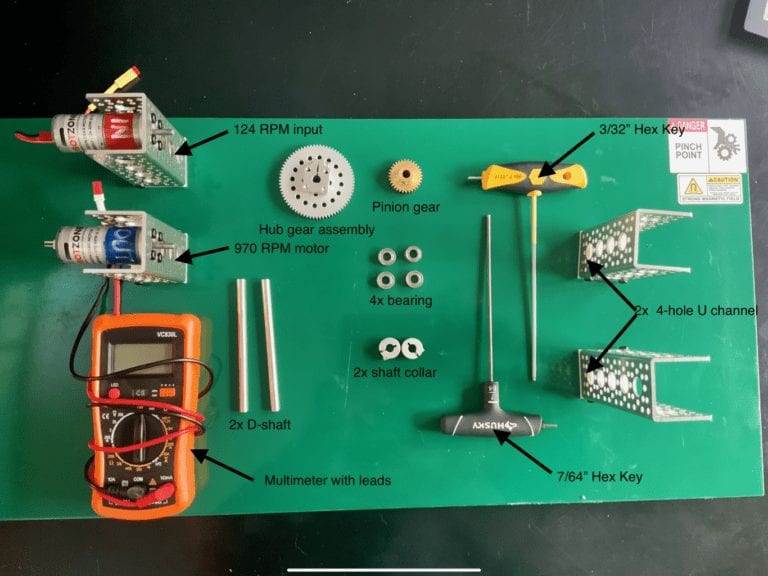

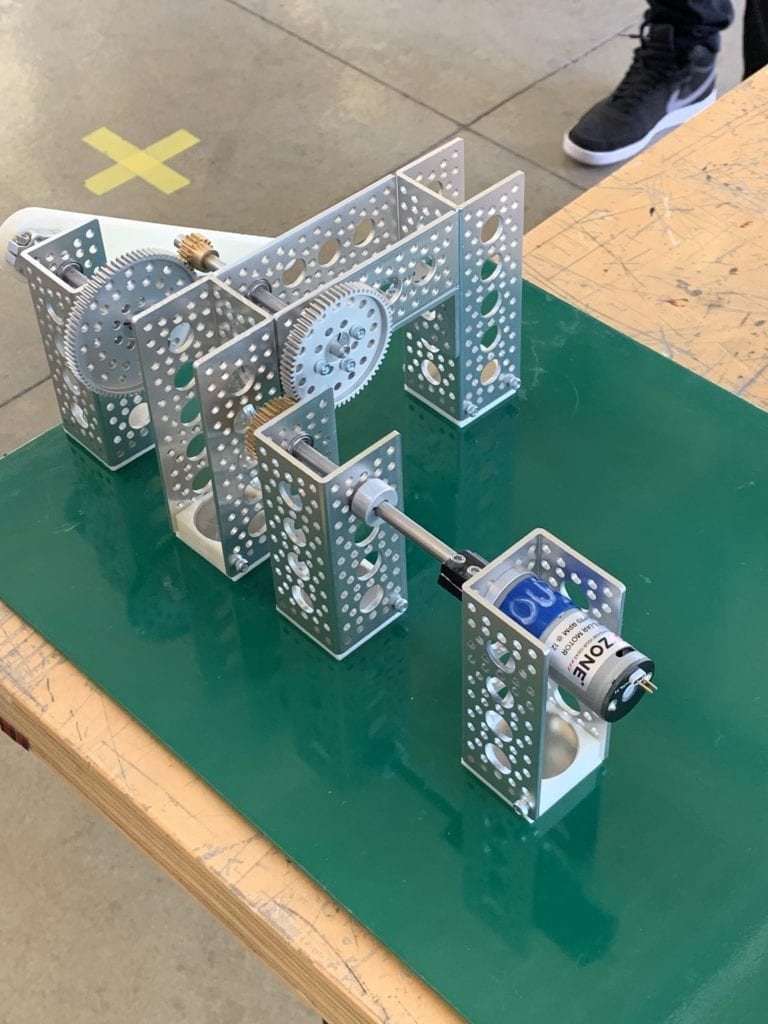

The Exploration Activity is a kit consisting of:

- Steel base plate

- Magnetic “pillars”

- Modular drive train components

- Tools

- Measurement devices

Kits are to be provided to groups of 3-5 students to demonstrate important concepts through the guided activities and then through further exploration of different configurations on their own.

Verification

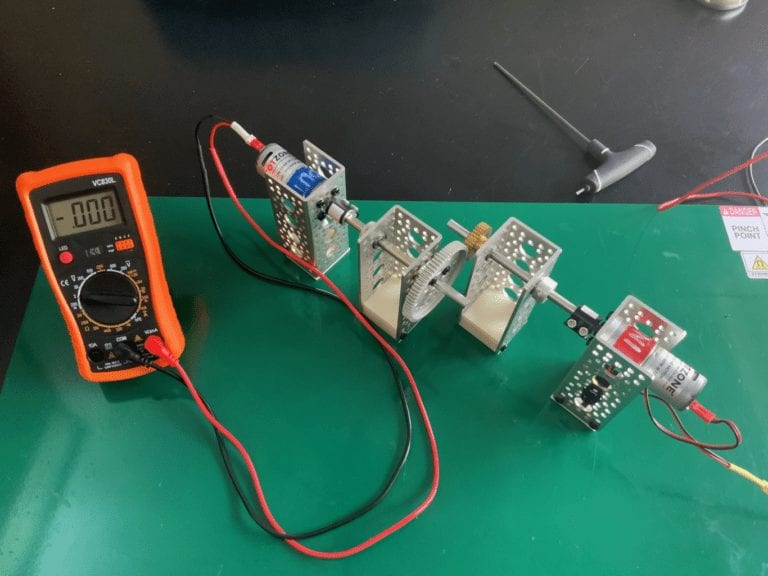

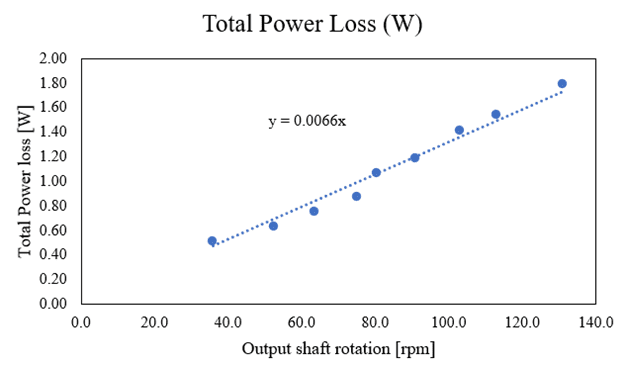

Power Loss Test

This test was performed to verify power loss in the system. The plot above shows that when the shaft speed increases or in other words the power supply voltage increases, then the loss in power within the two motors increases. The rate of which the loss occurs can be seen is nearly linear and expected if the loss in the system remains constant.

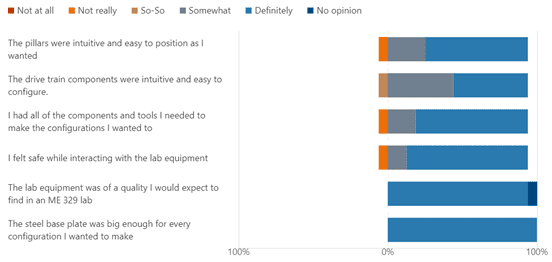

Ease Of Use

During our testing we were able to get test our design with past, present, and current engineering students. There feedback was compiled in the figure above and the feedback came back positive. There were a few comments throughout the testing that we took into consideration such as making the lab manual more descriptive and making small changes to some our components.

Magnet Power

In the early stages of the design we tested to see if the magnetic force would be strong enough to hold not just the pillars but the whole gear train configuration. The result when securing the multiple gear meshes to the input and output motors showed that there was no movement in the configuration.

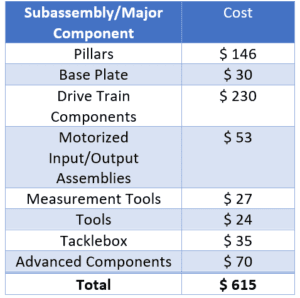

Cost

The total cost of $615 per kit may seem high, but considering these components will be used again for the final design activity, and that they could potentially be used for multiple sections for many quarters, we are confident the educational value is well worth the cost.